An Industrial Band Saw for Virtually Any Application

Cosen Saws, North America plans to showcase at least four fully automatic band saws suitable for high-volume production as well as a jack-of-all-trades utility toolroom band saw at IMTS.

Posted: June 9, 2020

Cosen Saws, North America (Charlotte, NC) plans to showcase at least five industrial band saws at IMTS 2020. The first four are fully automatic and come with a 1¼-inch blade and a 5-horsepower motor.

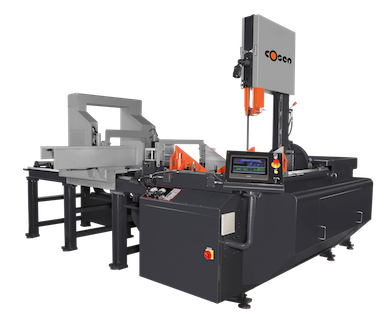

The company’s response to the market’s desire for more automation in structural steel fabrication, the AV-2026NC combines a vertical-tilt frame band saw with an automated feeder. Operators push a button and walk away until the job is completed. With a capacity of 20 inches by 26 inches at 90 degrees, the saw feeds up to 59 inches per single shuttle and can index up to 999 inches of material.

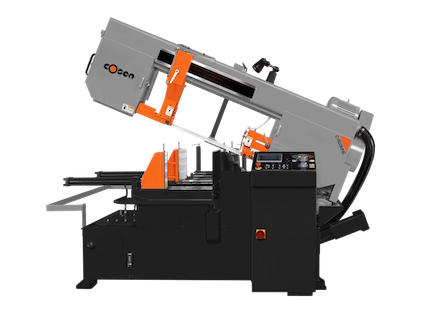

The horizontal scissor-style C-260NC is a fully programmable entry-level automatic band saw for high-volume environments. SNC (Smart NC) control system enables users to store 100 jobs, index material up to 999 inches, and manage work flow from an easy-to-use HMI touchscreen display. Footprint of 85 inches by 86 inches is great for small-to-medium-size shops. Round capacity: 10.2 inches; rectangular capacity: 10.2 inches by 11.8 inches.

The heavy-duty horizontal scissor-style C-510MNC with SNC control performs straight cuts or 60-degree-angle miter cutting. Round capacity: 14 inches; rectangular capacity: 13 inches by 20 inches.

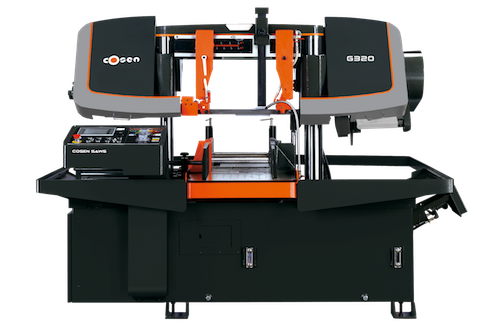

Equipped with a quick-approach bar system, Save-A-Blade feature, and SNC control, the dual-column G320 combines rigidity and state-of-the-art software for affordable high-volume production. V_Drive technology detects when material becomes more dense and automatically adjusts amperage to cut nickel-based metals like titanium and Hastelloy 25% to 50% more efficiently. Round capacity: 12.8 inches; rectangular capacity: 12.8 inches by 15 inches.

The compact, rugged VCS-310 vertical contour band saw comes with a cast aluminum table that can be adjusted to a plus/minus 15 degree tilt, an inverter blade drive system that allows for infinitely variable blade speeds, table t-slot, rip fence, built-in work light, and built-in blade welder. Equipped with 230V 1PH power; provides 8.6-inch height capacity and 11.96-inch throat capacity.

Booth N-236931