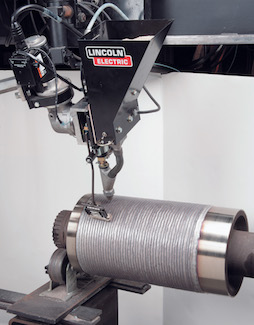

High-Carbon Metal-Cored Wire For Caster Roll Rebuilding

Lincoln Electric’s Lincore 420HC-S metal-cored wire for submerged-arc welding (SAW) may be used where higher hardness is required and on work rolls and backup rolls when water spray causes pitting on tool steel deposits.

Posted: June 22, 2020

The Lincore line of hardfacing and build-up wires from Lincoln Electric (Cleveland) are formulated for arc welding processes including FCAW-S (flux-cored self-shielded), FCAW-G (flux-cored gas-shielded), GMAW-C (metal-cored), and SAW (submerged-arc).

Most often used for caster roll rebuilding, Lincore 420HC-S metal-cored SAW electrode may be used in flat, horizontal, and circumferential welding positions. Because it produces a high-carbon, 420 stainless steel deposit, the wire may be used where a higher hardness is required and on work rolls and backup rolls when water spray causes pitting on tool steel deposits.

To offer options depending on weld thickness, the wire is available in the following wire diameters and package sizes:

- 3/32, 50-lb. coil

- 3/32, 600-lb. speed-feed drum

- 1/8, 50-lb. coil

- 1/8, 600-lb. speed-feed drum

The 50-pound coil is light enough for one person to lift and install on a wire feeder reel. The speed-feed drum offers a larger, bulk package for high-production environments; more wire in the package means fewer changeovers and less downtime for the welder.