How to Solve 8 Top Problems that Undermine Profitability in Metalworking Operations

Every ounce of additional productivity rung from each step in the process adds up to significant cost savings over time. From coolant and tooling to programming and scrap management, opportunities to increase efficiency abound.

Posted: June 18, 2020

PROFIT MASTERY COLUMN

BY TERESA PHILLIPS

There are eight common problem areas that affect operational profitability in metalworking operations. Here’s a look at those challenges, how they threaten profits, and what metalworking shops can do to counteract their effects to maximize growth.

- Machine Tooling

Numerous metal-based materials are used in metalworking. Based on their composition, these materials each machine differently. For instance, many superalloys are used in medical device manufacturing. End mills and inserts can burn up if they are not run properly.

Solution: Select the proper cutting tool for each material. Research shows choosing the most appropriate cutting tool for the material being machined saves as much as 15% on overall costs and improves machining productivity by 20%.

- Cutting Fluids

When not managed properly, cutting fluids are a costly expense. In addition to comprising up to an estimated 10% of the cost of a finished part, large volumes of waste coolant are costly to handle and haul away. Outdated and inefficient fluid-recycling systems are also problematic.

Oil-based coolant can also pose challenges. Most applications use a water-miscible fluid, but oil-based coolants are the best option for precision machining applications. When oil-based coolant residue gets inside the machine it can stain parts. These stained parts need to be cleaned.

Solution: Recycle cutting fluids in-house with a turnkey system that provides machines with a consistent source of clean fluid at the proper concentration. Such systems have been proven to:

- Increase tool life up to 25%

- Reduce haul-away costs by up to 90%

- Lower coolant purchases up to 75%.

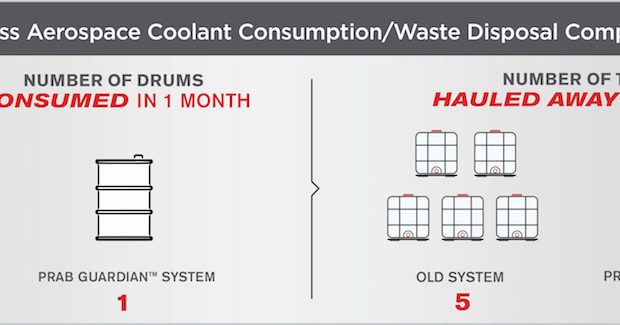

Koss Aerospace, a Tier-1 manufacturer of aircraft components and assemblies in Mississauga, Ontario, realized significant savings after updating its filtration system. The waste cutting fluid had an obvious foul odor and was challenging to maintain.

Koss used a simple coalescence system to recycle fluid, a labor-intensive process that required significant downtime for sump maintenance. With an average sump size of 132 gallons (500 liters), the system also lacked the capacity to process all the fluid from the company’s 26 machining centers. As a result, Koss was disposing of excess spent coolant and incurring significant haul-away costs. After replacing the system with a modern centralized coolant recycling system, coolant purchases fell 75%.

When it comes to oil-based coolant, consider switching to a synthetic coolant if the application isn’t in precision machining. Synthetic coolants have excellent cooling properties that provide long life in the sump, which reduces both maintenance and waste. Also, synthetic coolants don’t contain mineral oil. Parts come off the machine cleaner and, as a result, don’t require washing and blow-off.

- Setup and Fixturing

It’s not uncommon for half of the setup time in milling and turning applications to be wasted.

Solution: Use quick-change tooling that allows the operator to switch out tooling via a quick-release screw. Operators are able to easily remove the current tool and replace it with no additional setup.

With regard to fixturing, using a workholding vise enables quick change-outs and minimizes downtime. Also, having multiple fixtures nearby and ready to use saves time. This makes switching parts quick and easy when the machine cycle is complete.

- Technology and Innovation

With technology constantly changing, you risk losing your competitive advantage if you don’t stay abreast of innovations.

Solution: Using integrated tools to expand functionality is a way to drive efficiency. For example, a tool for a 5-axis machine that drills, countersinks, and chamfers – instead of three separate tools – reduces the number of individual tools required to complete a job.

- Metal Removal Rate

Lackluster metal removal rate (MRR) – the amount of material removed, typically per minute, while machining – and manual processes can significantly slow production.

Solution: Increase MRR by using the correct toolpaths, depth of cuts, speed, carbide grades, and geometries.

Deburring is another area of production that can be improved. By changing from manual deburring to a deburring wheel, especially if it’s automated deburring, will save a significant amount of time immediately and over time.

- Programming

A machine that’s not programmed properly can create unneeded operational steps, which contributes to overtime and lower production rates. Further, outdated control systems and programming cause many inefficiencies, such as low productivity, high maintenance, and low output.

Solution: Update or replace outdated control systems and/or hire a reputable and knowledgeable automation company for programming. Updating machine programming or adding automation to current operations:

- Reduces time to market

- Improves quality

- Makes the workplace safer

- Increases output

- Reduces labor requirements.

By remotely monitoring equipment, real-time data can be used to proactively adjust maintenance programs and production schedules. KMC Global Controls & Automation of Kalamazoo, Mich., works with manufacturers to program machines to reduce labor costs. Features such as maintenance reminders, interactive fault screen controls, user-friendly human-machine interface (HMI) screens, and cloud-based machine monitoring that automatically shuts off inessential operations when they’re not being used (see the next discussion item) increases machine utilization without adding costs.

- Energy Waste

Operations that run when they aren’t needed are a primary waste of energy. Pumps, blowers, conveyor motors, blending, and vessel agitation are a few examples of equipment and processes that are left to run for long periods of time even when product or materials aren’t being produced.

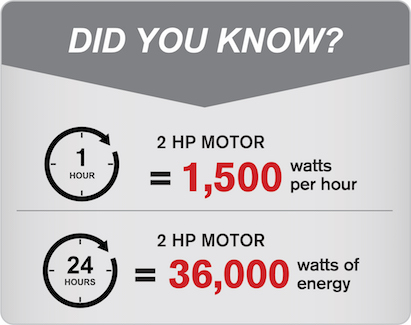

And it’s not just large power consumers that are the culprits; wasted energy from small motors add up over time. For example, one 2-horsepower motor that draws 1,500 watts/hour uses 36,000 watts (3.6 kilowatts) of energy in one day.

Solution: Four ways to increase energy efficiency and lower costs are to:

- Replace motors with lower-horsepower motors that match the power to the need of the application.

- Employ speed- and load-altering devices to efficiently manage the delivery of material from one process to another.

- Tests motors during the initial start by running them for a short period of time. Then, pause the motors until product arrives.

- Utilize cloud-based machine monitoring systems to identify energy wasters that can be shut off during periods of inactivity.

- Scrap Management

Manually handling and/or failing to process scrap in-house before it’s sent to the scrap dealer is a considerable source of lost revenue. Scrap that isn’t effectively processed takes up valuable space and takes operators away from production. It also accrues high haul-away costs and yields reduced prices from scrap dealers.

Solution: Invest in processing equipment that separates chips from fluid and reduces large piles of turnings to small chips that brings a higher price per pound from dealers who prefer dry chips. Such equipment includes:

- Conveyance systems automate moving scrap from the point of generation to the processing equipment and then to recycling containers. Conveyors create a safer shop by significantly reducing operator interaction with material and decreasing forklift traffic.

- Crushers and shredders turns large piles of turnings into shovel-size pieces.

- Wringers/centrifuges separate chips from cutting fluids, create dry chips, and collect spent fluid.

- Briquetters compress wet chips into dry, compact pucks that are easy to re-melt, transport, and store.

Where to Begin?

Maximize profits by focusing on these eight problem areas. Prioritize them based on which ones will produce the greatest cost savings and then systematically address each problem, one at a time.