Press Brake Tooling For Virtually Any Bending Challenge

Mate Precision Tooling supplements its extensive range of standard hardened and precision-ground press brake tools with modified standard and custom designs for special bending challenges.

Posted: June 26, 2020

Mate Precision Tooling (Anoka, MN) adds modified standard and custom press brake tools (PBT) to its extensive range of standard hardened and precision-ground PBTs. All tool styles in North America are available in American precision style, European precision style and Wila Trumpf style.

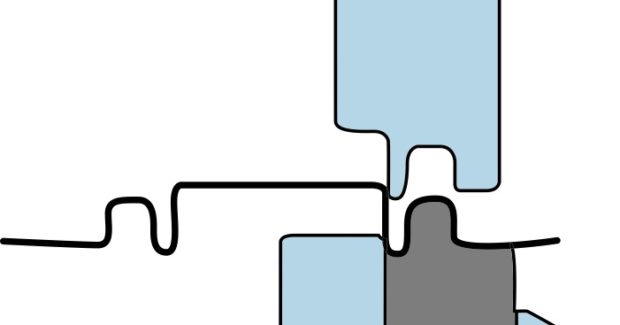

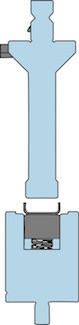

While standard tools meet the needs of most fabricating operations, bending variations may require modifying the angle of a standard punch or die a few degrees. Sometimes the angle of the standard punch or die needs to be modified. This is easily accomplished because the induction hardening depth is 0.118-inch to 0.157-inch (3mm to 4mm). This allows material removal to modify an angle or change a radius without jeopardizing the structural integrity of the tool.

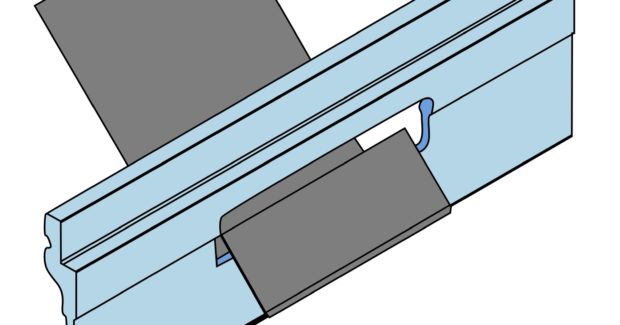

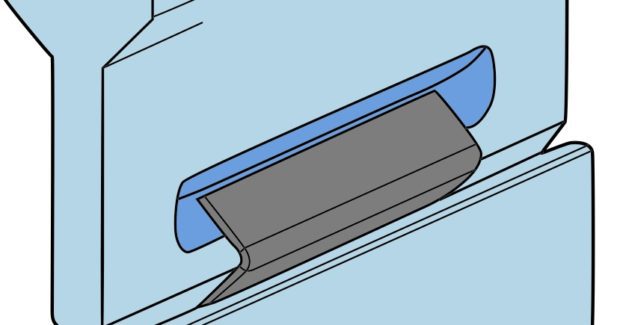

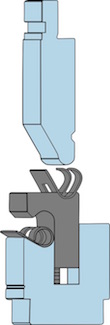

Other frequent modifications include cutting a window or relief pocket to provide clearance so a formed part doesn’t collide with the punch during the forming process.

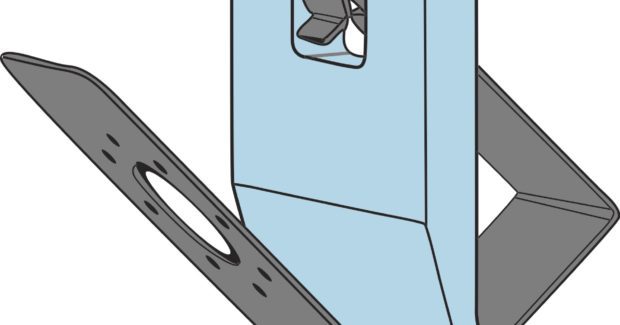

When a standard or modified standard isn’t the best solution, Mate’s application specialists will design a custom tooling solution. Frequent requests include forming multiple bends in one stroke to decrease production costs by increasing the number of formed parts per hour; for example, a hinge curl tool that forms the curl in two or three strokes. Mate offers an endless variety of custom press brake tools for virtually every special bending requirement.

All tools, whether standard, modified, or custom, are guaranteed to satisfy bending application needs and backed by 100% customer satisfaction guarantee.