Reshoring Is Increasingly Appealing to Casting Buyers

The growing U.S. manufacturing trend toward reshoring means many companies are seeking domestic-made products. On the investment casting front, Franklin Bronze Precision Components says it can shorten supply chains and offer fast part delivery for manufacturers.

Posted: June 22, 2020

Reshoring is the trend of bringing manufacturing from overseas back to its local origin – the United States. The tariffs on China, Canada and Europe imports were designed to both level the global trade playing field and incentivize U.S. companies to bring manufacturing back to America. Now, it seems that the COVID-19 pandemic may have accelerated this trend.

The COVID-19 pandemic has disrupted complex global supply chains from logistics (closed borders, idling ships, and reduced routes) to operational capacity concerns which impact production schedules and order fulfillment.

For the investment casting industry, many companies are looking to return to domestic made castings citing common reshoring reasons: high overseas prices, shipping costs, long lead times and logistical issues. Equally as often, casting companies want a local partner to collaborate with to meet the market challenges of rapid innovation and product development. Changing consumer behaviors demand rapid and iterative innovation which can be more effectively achieved by shortening supply chains and bringing producers closer to final consumers.

“When evaluating a local supplier, companies should look at total cost, including transport, duty, freight, carrying cost of inventory, quality and delivery, rather than simply labor costs, as happened in the 1990s’ offshoring wave. Having suppliers close to home, eliminates much of this “extra” cost and logistic headache – and provides opportunities to customize products,” explains Kevin Weaver, industrial sales manager.

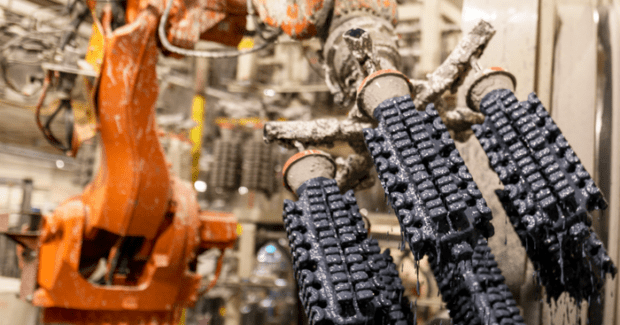

“Here, at Franklin Bronze, we offer speed to market and close collaboration with our customers, an advantage for those looking to reshore,” he continues. “With robotic processes, in-house tooling and castings machining, we are able to react and deliver parts fast.”

“By working with customers close to home, we are able to technically support in designing and developing parts that are manufacturing friendly to minimize cost and maximize performance. Our in-house metallurgical engineer is always available to propose alternative metals and treatments that minimize cost without compromising the function or performance of the component. 3-D printing is available to produce prototypes as well as small lot production in the shortest time possible.”

For more on reshoring and Franklin Bronze: https://www.franklinbronze.com/why-reshore-secure-your-supply-chain/