CAD/CAM Software Suite Adds Virtual Machining, Additive Manufacturing, and Automation Capabilities

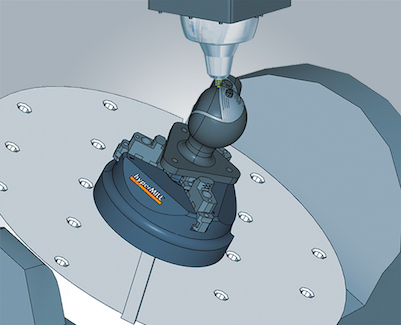

The latest versions of the hyperMILL CAD/CAM software suite from Open Mind Technologies AG encompasses a wide range of user-friendly enhancements and new machining strategies to advance the capabilities for accurate, efficient 3D and 5-axis machining.

Posted: July 6, 2020

Developed with Industry 4.0 in mind, the latest versions of the hyperMILL CAD/CAM software suite from Open Mind Technologies AG (Needham, MA) encompass a wide range of user-friendly enhancements and new machining strategies to advance capabilities for accurate and efficient 3D and 5-axis machining.

VIRTUAL Machining Optimizer provides solutions over and above simulation and identifying error conditions. These capabilities improve toolpaths that are traditionally calculated in the CAM engine, and incorporate knowledge of the part model, tooling, the toolpath calculation and collision check engine, and the machine tool model with its physical constraints. Individual part programs may be linked with smooth and safe connections, enabling the cutter to remain close to the workpiece.

A new Automation Center allows users to automate job list creation in hyperCAD-S, serving as both a development and runtime environment. Features include the ability to select and position the clamping device as well as define a uniform process for all programmers.

ADDITIVE Manufacturing supports 3D printing and subtractive machining on one machine tool, including filling strategies for planes and free-form shapes in 2D and 3D sections. Applications also include hybrid machining to fix damaged parts and additive machining of an existing component.

The integrated MAXX Machining finishing module enables use of conical barrel cutter technology to reduce cycle times by over 90%. Three modules – finishing, roughing, and drilling – are ideal for planar, ruled, and curved surfaces often found in complex 5-axis components.