VELO3D Qualifies Hastelloy X for Sapphire 3D Metal Printer

A new process enables the industrial gas turbines market to print components it couldn’t before, including those that must withstand extreme high temperatures.

Posted: July 13, 2020

VELO3D (Campbell, CA) has released a production process for additively manufactured parts in Hastelloy X. This is a nickel-based alloy, suitable for the laser powder-bed fusion (LPBF) process, which is very resistant to corrosion cracking and oxidation. Hastelloy X is most often used to manufacture parts for combustion-zone components in gas turbine engines due to its high temperature strength.

“Power generation applications such as industrial gas turbines are a key focus for VELO3D, so it is important that we qualify the right materials to serve that market,” says Benny Buller, founder and CEO of VELO3D. “We will continue to add more of these types of compatible materials that enable customers to print parts they couldn’t before, yet with even better material properties than those produced by traditional manufacturing.”

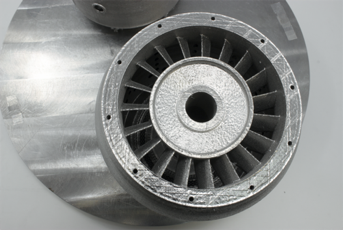

Air mobility and power generation pioneer Sierra Turbines recently partnered with VELO3D to print a prototype for their 20-kilowatt microturbine engine with a unicore in Hastelloy X. They aim to print 95 percent of their engine through metal additive manufacturing, taking advantage of the design freedom possible through VELO3D’s SupportFree process.

“Sierra Turbines wants to lead aerial and power systems into a new way of manufacturing,” says Sierra’s founder and CEO Roger Smith. “That means pushing the limits of what is possible to create a more heat-resistant, lower maintenance, and higher-performing gas microturbine. VELO3D’s technology makes this the ideal manufacturing solution for turbines.”

VELO3D is well-known for enabling geometric freedom through its patented SupportFree process, which reduces the consideration of support structures for complex passageways, shallow overhangs and low angles. Coupled with its non-contact recoater, VELO3D’s printing process can create the intricate cooling passageways and fuel delivery channels needed to achieve high-output fluid transmission and electrical power.

VELO3D’s Sapphire metal AM printer is now compatible with Titanium64, INCONEL alloy 718, Aluminum F357, and Hastelloy X.