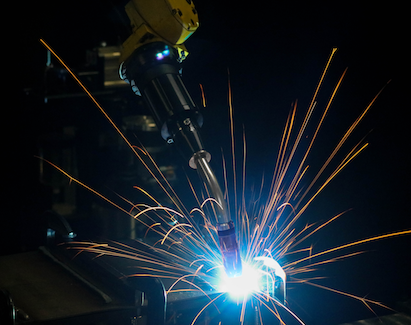

How to Choose the Right Type of Contact Tip for Your Robotic Welding Cell

Contact tips may be tiny, but using the wrong type or replacing them too soon can have a huge impact on productivity. Here’s what to consider to improve results and save money by properly matching tip type to application.

Posted: August 12, 2020

WELDING TIPS COLUMN

BY JUSTIN CRAFT

Contact tips are often referred to as the smallest fuse in the fuse box that is your robotic welding cell. But this small fuse can have a big impact on productivity. In terms of overall efficiency, the contact tip is key.

Contact tips depend on repeatability to be effective in the welding process. Here’s how choosing the right one for your application can improve results and save money.

How Do Contact Tips Affect Efficiency?

The job of the contact tip is to transfer the welding current to the arc and guide the welding wire as consistently as possible. If either of these two factors degrade, the overall welding process also degrades, affecting quality.

When an operation changes contact tips every few hours, there’s an obvious effect on productivity. It requires the weld cell to be shut down, and the operator may have to enter the cell to change out the tip. If the robot is buried inside the welding line, contact tip changeover takes even longer.

Not only are these changeovers inefficient, but they also introduce the potential for mistakes. Every time a human interacts with the robot, there’s a risk of incorrect consumable installation or other improper adjustments that can lead to poor-quality welds and costly rework.

Choosing the right tip depends on the results you’re looking for and the needs of the application. In the automotive industry, for example, choosing a quality contact tip is critical because unplanned downtime is the enemy of a high-volume multirobot operation. Contact tips in these applications need more wear resistance.

A high-quality contact tip provides a longer life and a more consistent and stable arc. Longer tip life results in more robot uptime, less time wasted on nonvalue-added labor for tip changeovers, and reduced human interaction with the robot that could lead to error. But the contact tip itself isn’t the only factor impacting tip life; welding wire, part fit-up, robot programming, and grounding also contribute.

Different Types Of Contact Tips

Understanding the differences between the several types of contact tips will help you make the best choice for your operation.

Copper contact tips. Contact tips made from this material are the most conductive to transfer welding current. However, copper is also the softest option and will keyhole (or wear the bore unevenly) much faster. If keyholing is a pain point in your operation, this may not be the best choice.

The initial cost of copper contact tips tends to be cheaper than other options.

Chrome-zirconium contact tips. This alloy provides better wear resistance and longer life than copper tips, holding up better to the demands and increased arc-on time of robotic welding. They are slightly less conductive than copper tips, but still sufficient for most robotic applications.

HDP contact tips. They can last 10 times longer than copper tips — and up to 30 times in some cases — depending on the application and waveform being used. Operations may be able to go from changing contact tips every two hours to only changing tips once a week.

HDP contact tips are engineered to endure wear better, providing increased resistance to arc erosion in pulsed welding, as well as spray transfer and CV MIG. The precise fit between the tip and the wire also results in good arc stability to help produce high-quality welds. Because HDP contact tips reduce the impact of the welding current decline over time, they can provide a more stable and consistent arc over the life of each contact tip.

These tips work best in applications that use high-quality copper-coated solid wire.

Common Pitfalls With Contact Tips

Once you understand the types of contact tips available, there are numerous factors to consider when choosing the right tip for your application. Here are some common mistakes operations make when choosing contact tips so you can avoid the same pitfalls.

Only considering price. It’s important to look beyond the initial price and consider the big picture, which includes the downtime and labor required for changeover along with any quality issues that may be happening in the weld cell. If a contact tip lasts three times as long, the robot can continue to weld instead of being down for a tip changeover — and there’s less human interaction inside the cell.

Ignoring ID tolerance issues. The size and cast of the welding wire are important in deciding on contact tip type. Some tips need to be undersized for the welding wire used, while some tips need to match the wire size. Also, the same exact wire will vary in the necessary contact tip size depending on if the wire comes in a small spool or a 1,000-pound barrel.

For most copper and chrome-zirconium tips, it’s recommended to undersize the contact tip by a single wire size when using a 500-pound barrel or larger of wire due to the wire cast. With smaller sizes of wire packaging, use contact tips that match the wire size. The goal is to maintain a clean, consistent contact between the wire and the tip so the weld current is conducted as efficiently as possible.

Using poor-quality wire. In most cases, poor quality welding wire will lead to poor results from your contact tips. This is due to the lubrication on the wire and the consistency of the wire diameter; inconsistent wire diameter wears the tip faster.

Choosing a higher-quality wire can improve tip life and produce better results. Also, wires without a copper coating and cored wires wear tips much faster. Using copper-coated solid wires typically slows contact tip wear.

Not being open to change. Some companies think the status quo is fine because they aren’t experiencing issues. They change tips in the robotic welding cell every couple hours even if they don’t need to be changed.

Looking at the true length of the tip or investing in higher-quality tips could optimize overall process, saving money as well as unplanned downtime and reducing the need for nonvalue-added labor hours.

Analyzing The Robotic Operation

If contact tips are being removed proactively even when there’s no keyholing, burnbacks, or erratic arcs, there could be potential to get more life out of them. So how should you analyze your robotic welding operation to determine when to change to a different type of contact tip?

Contact tips react differently to different applications, so the first step is to run trials with varying quality levels of tips. This will provide an accurate comparison and a level set for expectations. Run each tip to failure, including the current brand, rather than proactively changing the tip on a set schedule. Be sure to log the time each part lasted. Ideally, run multiple contact tips in any trial to eliminate any outliers.

This type of trial can help identify how much labor time is spent on tip changeovers, how much robot uptime can be achieved, and what failures are occurring with each type of contact tip.

If an operation previously experienced 10 burnbacks a day and reduces that to zero by using a higher-quality contact tip, this can help eliminate unplanned downtime.

Optimizing Contact Tip Efficiency In Robotic Welding

It’s important to look beyond the purchase cost and consider the big picture to best evaluate the potential productivity, weld quality, and efficiency gains of certain contact tips. The benefits can be especially significant in robotic welding applications, where regular contact tip changeovers can be greatly reduced.