Nanometer-Level Motion Control for Micromachining

As micro-processing quality requirements become more demanding, legacy systems don’t always meet accuracy and repeatability specifications. Built around ALIO’s 5-axis laser gimbal, 6D Laser’s integrated infinite field of view (IFOV) system increases processing speed while eliminating errors from field stitching.

Posted: August 26, 2020

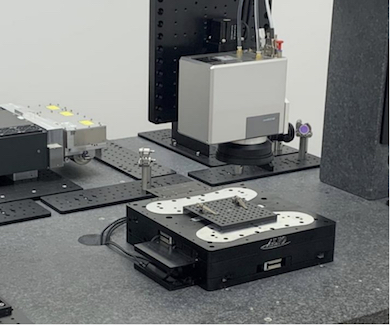

6D Laser LLC is an affiliate of nanometer-level motion control specialist ALIO Industries Inc. (Arvada, CO) that integrates ultrafast laser processing with precision multiaxis motion systems by partnering with key component and subsystem suppliers. The company has partnered with Scanlab GmbH to develop an unlimited field-of-view (UFOV) scanning solution for planar processing that combines the precision galvo scanning of Scanlab’s XLSCAN system with ALIO’s precision monolithic XY stages.

Conventional UFOV systems that control a scan head and XY stage typically use high-speed galvo scanners to compensate the slower stage’s following error. A tracking error is induced by the mass inertia and the design of each system’s servo control loop.

This means the real position of the laser spot lags the target position. Therefore, the real laser spot position is correct only after a certain amount of time has elapsed – and the system momentarily oscillates. Because of this, any imperfections in the stage error mapping, or galvo field correction, will impact overall precision due to the time lag in the servo loop cycle.

Attempting to extrapolate the slower stage’s behavior using estimated values works only at slow speeds and for nonabrupt motions. Especially at corners and sharp features with high acceleration or deceleration rates, this tactic can produce significant position errors.

XLSCAN uses intelligent filters to control the scan head and stages so each system’s physical limitations are taken into account before processing in an integrated trajectory plan. The positions of both systems are coordinated to submicron-level precision within a microsecond. Precision is limited only by the image field calibration and stage error mapping.

Automatic laser control can correct the spot distance relative to the velocity and the laser power across the scan field. For increased throughput, four scan heads can be controlled with one XLSCAN controller.

In addition, the laser signal can be raised or attenuated in accordance with application requirements for straight as well as rounded laser markings. Multiple parameter changes and jumps for individual vectors are also possible.

“Infinite field of view (IFOV) processing systems offer considerable advantages over traditional field-stitching systems by combining the high-speed scanning of galvos with the large field sizes available with motion control stages,” says 6D Laser Chief Technology Officer Stephen Uhlhorn. “This increases processing speed while eliminating errors from field stitching. However, current systems are limited to processing 2D planar substrates. As geometries become increasingly complex, the need to control angle of incidence (AOI) for nonplanar substrates becomes crucial. Our system solves this problem.”