Quickly and Easily Measure Carbide Tools and Metal Blanks

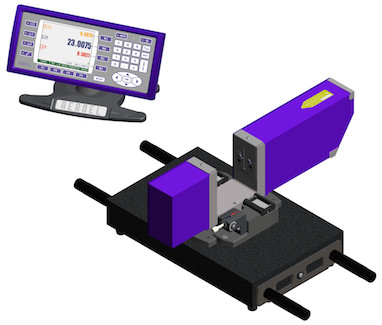

Confirm tolerances without gauge remastering with the Aeroel MECLAB.T40 from Marposs. The benchtop laser measurement system doesn’t require a PC, so it’s ideal for use on the shop floor.

Posted: August 26, 2020

Available from Marposs Corp. (Auburn Hills, MI), Aeroel’s MECLAB.T40 is a high-precision laser instrument for quick and simple diameter measurement of hard metal blanks and full carbide cutting tools, odd or even edges. The system checks tolerances by comparing actual dimensions to programmed limits; and is suited for offline checking of drill bits, end mills, reamers, and cutting tools as well as the diameter, ovality, and straightness of hard metal blanks and ground pins or cylinders. It doesn’t require a PC, making it ideal for use on the shop floor.

The system’s extremely accurate and repeatable Xactum XLS40/1500/B laser micrometer provides a measuring field up to 40 mm, linearity of ± 0.5 μm, repeatability of ± 0.05 μm, and permanent self-calibration. Aeorel’s exclusive NO-VAR technology eliminates the potential of measuring drift due to changing room temperature by programming the coefficient of thermal expansion of the part.

Offered in manual and automated versions, the system achieves highly reproducible results regardless of operator skill. The noncontact device enables measuring of different components without gauge remastering.

The operator inserts a part onto a double-V fixture mounted on a manually driven slide equipped with a magnetic digital readout scale. This displays the displacement of the part itself with the position continuously displayed on the screen. Using a guided procedure, the operator seeks the starting point, moves the part to the measurement position, and starts the cycle.

During this, the part is manually or automatically rotated to a measurement period set by the computer. During rotation, the laser sensor scans the part at 1,500 samples per second and stores all measurements related to the position of the part’s upper and lower edges.

Data-processing software performs accurate and repeatable measurement of cutting diameter and runout for both odd or even fluted parts. Results are updated and displayed in real time, giving the operator the information when to stop the check. When measuring round parts, i.e. hard metal blanks, the software checks diameter, ovality, and end runout.