Totally Tubular: Take Profile Design to the Next Level

One of the fastest-growing sectors of North American metal manufacturing is laser processing of tubes and profiles. Design software and machines that automatically perform multiple manufacturing steps are making this complicated fabrication process cost-effective for smaller companies.

Posted: August 25, 2020

THE CUTTING EDGE COLUMN

BY TOM BAILEY

Mechanical engineers are well-acquainted with the benefits of using tubes and profiles to fabricate frames: excellent strength-to-weight ratios and aesthetic appeal. There are many assemblies where sheet metal and a tube or profile would provide equal levels of rigidity, fixing, or alignment, so product designers often have a choice in the matter. How to decide?

Until recently, the benefits of tubes and profiles had to be weighed against the material’s drawbacks. Specialized tools and/or specialized fixturing was often required, and generally larger stock sizes than flat sheet metal complicates the logistics of moving the material around a factory.

Frames are as diverse as the products to which they provide shape. However, whether it’s for a combine harvester or a hospital bed, they share common characteristics. They must be able to handle the final product’s weight and stress loads, they all have attachment points, and their shape roughly corresponds to the end product’s shape. These requirements dictate material thickness and length; the size of individual pieces; what shape each piece is cut, machined, or formed into; what holes and features must be added; and how the frame’s pieces are assembled and joined.

Pulling all this together into anything more complex than, say, a rectangle with four members joined at the corners is more complicated than cutting and bending sheet metal. When compound corner angles come into play, even seasoned saw operators can make an error in setup, material placement, and/or cut. And that’s just the first step: Next the cut-to-length tube members must be placed on a drill press or mill to add holes and slots. Some holes need to be tapped to receive fasteners. Once all that’s done, all these oddly shaped, separate pieces must be jigged together for welding.

Seasoned operators overcome these challenges every day. For fabrication companies that don’t specialize in the process, however, they can seem like insurmountable barriers: Why add all that handling and logistical complexity to a factory? As a result, frames, shields, and structures that could benefit from incorporating tube and profile components instead continue to be fabricated with flat stock or structural members.

Hardware Advancements: Evolution of a Machine Category

Fabricators began experimenting with using laser light to cut tubes and profiles not long after they began using lasers to cut sheet metal, in the 1970s and 1980s. They put a fixture meant to hold a tube on a sheet metal laser cutter and used the machine to make holes. Rotary attachments came next, allowing the machine to position the tube automatically for placing holes.

The first dedicated tube-cutting laser machines featuring purpose-built material-handling and cutting units were introduced in the 1990s. Today, machines can provide full-service fabrication of tubular components in one manufacturing step, eliminating the many handling and locating steps that would otherwise be involved. Also, in addition to processing tubes and closed profiles, machines can process extrusions, structural members, and open profiles such as C-channels and angles.

After a bundle of raw material is automatically loaded into the laser cutter, it performs trim-off; cuts through-holes, slots, and features; and cuts the finished component to length. Machines can be equipped to bevel cut and tap holes as well, eliminating all secondary processing before the component moves on to welding and finishing.

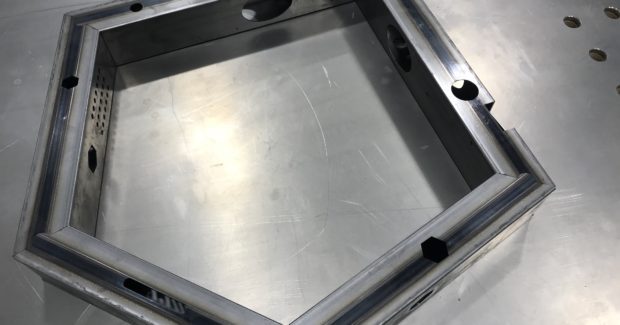

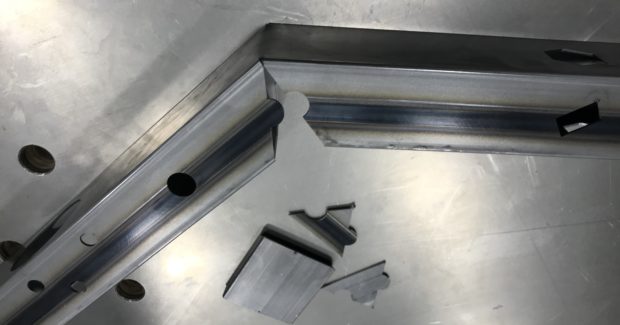

Because they use a laser to cut, machines also can go way beyond making holes and cutouts. In addition to enabling common features, such as interlocking slot-and-tab designs, to be easily added, laser cutters speed up downstream assembly and welding processes.

Software Advancements: Assemblies Made Simple

As important as tube and profile laser cutters are for fabrication companies that want to expand their capabilities, CAD/CAM software for component and assembly design enables designers and manufacturing engineers to easily incorporate tubes and profiles into products without the logistical and handling nightmare of manual processing.

Programs can design assemblies from a single stick of material. In much the same way that 3D CAD systems unfold sheet metal parts to determine what the flat blank should look like, software can unfold a formed assembly into a straight tube and add all the relief cuts required for the tube to be cut and formed into shape by hand. Frames can even be designed to be self-fixturing: Once bent into the final shape by hand, slot-and-tab features can be used to lock the frame in place. Welders can work without having to hold or align any part of the assembly.

The laser cutters also can automatically detect and orient weld seams, and load and unload cosmetic materials without marring the parts.

Cost-Effectively Expand Your Company’s Capabilities

The high strength of tubes and closed profiles give shape, rigidity, and durability to a frame. In addition to allowing for all required steps to be handled automatically by equipment, laser cutters boast impressive capabilities beyond just speeding up tubular assembly production.

Fortunately, turnkey tube-cutting systems are available for around the same price as automated sheet cutters, opening the door for smaller fabrication companies to benefit from the technology. As the cost to produce components goes down and the productivity of laser tube processing goes up, more and more companies are looking to introduce tubes into their assemblies. Considering all this, it’s not surprising that one of the fastest-growing sectors of North American manufacturing is laser processing of tubes and profiles.