Turnkey Deep Hole Drilling Solutions

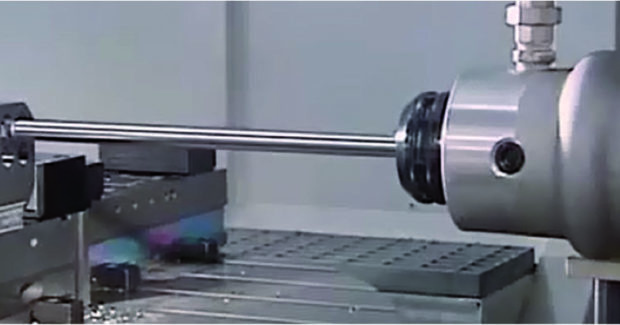

Why buy a new machine when you can convert an existing piece of equipment for much less money? Somex MAX spindles and accessories can be added to transfer machines, special-purpose machines, and turning machines to perform deep hole drilling.

Posted: August 28, 2020

Somex, a member of Suhner Industrial Products Corp. (Rome, GA), provides a less-expensive way of adding deep hole drilling capability to a factory. The maker of MAX spindles and peripheral components offers custom solutions capable of drilling 100x times deeper than a 12-mm-diameter hole. Modules can be integrated into transfer machines, special-purpose machines, and conventional turning machines to provide substantial cost savings.

To prove the design and performance of its solutions, Somex conducts tests at the factory using single cutting edge and carbide spiral drills up to 70x diameter under real production conditions. In this way, the brand delivers practical and realistic results to customers.

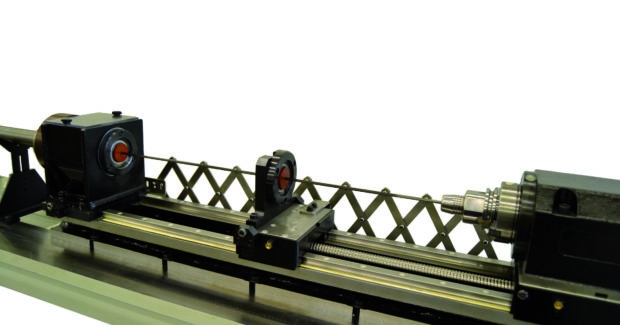

Deep hole drilling typically requires a pilot drill 1.5x the diameter, or a drill guide bushing followed by drilling. Somex combines the guide bushing with a chip basket so both items travel in unison. Guide bushing movement is air-driven, providing much closer contact to the part while preventing the escape of coolant. (Longer drilling applications may require a support bushing to stabilize the drilling tool.) The degree of accuracy as measured by deviation from the part’s theoretical center line is greatly enhanced by the slow, counterclockwise rotation.

For deep hole drilling applications greater than 18 mm in diameter, Somex can equip its MAX machining units with BTA or Ejektor drilling systems. Coolant and chip management is accomplished through the spindle center. The emulsion is collected at the back end of the spindle, filtered, and pressurized to re-enter the coolant system, a solution often used in high-volume precision parts manufacturing such as the automotive industry.