A Tale of Two Growth Strategies

A small Ohio company outpaces its market with new expertise and a new compensation system.

Posted: September 4, 2020

EDITOR’S FORUM

BY STEPHANIE JOHNSTON

In mid-August, the National Association of Manufacturers (NAM) announced its 2020 Manufacturing Leadership Awards. In addition to heavy hitters like Ford and General Motors, IBM and Boeing, a much-smaller company earned two awards for embodying the creativity and resilience of U.S. metal manufacturers.

Since 1959, family-owned Humtown Products in Columbiana, Ohio, has manufactured and repaired sand cores and molds for foundries, which in turn produce parts and equipment used in agriculture, construction, mining, defense, and transportation.

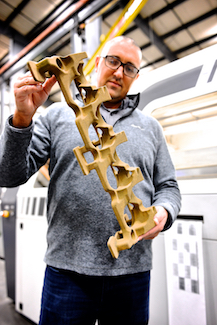

A strong believer in looking toward the next manufacturing space “so you don’t end up being out of space,” as CEO and President Mark Lamoncha puts it, the company decided to look into additive manufacturing. Mark and his son envisioned the technology not as a replacement for conventional processes, but as a complementary process that would enable customers to retool more quickly. “We could see 3D sand printing had advanced to where we needed to take a risk,” he says.

In December 2018, after more than five years of research, Humtown launched an additive manufacturing division with four ExOne S-Max industrial 3D printing systems. The following May, Mark Lamoncha told The Youngstown Business Journal Daily that 3D business was expected to increase an estimated 80%. In addition to winning new business, the move earned Humtown NAM’s 2020 Engineering and Production Technology Leadership Award as the industry’s first company to commercialize 3D-printed sand cores and molds.

Introducing the ‘Industrial Athlete’

As all business leaders know, keeping up with technology is only half the equation for success. Only an inspired workforce can optimize a technology’s potential to grow revenue.

During the Great Recession, Humtown lost more than 80% of its workforce. Realizing that remaining competitive would require fewer employees to produce more, Mark Lamoncha remembered that Lincoln Electric counterintuitively launched an incentive bonus compensation plan in 1934, the height of the Great Depression.

Inspired by that example, he developed and patented a real-time performance reporting tool. The Visual Earnings System uses algorithms to calculate per-unit labor cost as an employee runs a machine. Results are displayed for everyone on the shop floor to see. Video game-like visuals, such as fireworks going off on an employee’s screen when they reach $20 an hour and flames when they hit $30, are incorporated for further motivation.

Productivity has increased by 350% to 400% at, with one job, 1,440 instead of 400 or 500 parts in an hour. The scrap rate fell from 8% to less than 3%. In the process, managers learned employees perform better in 6-hour than 8-hour shifts. Employees may come in at 6 am and leave at noon to, for example, continue their education at a local trade school or college.

“Some make as much as $100 an hour on a project, which means one person is doing the work of 10,” Mark Lamoncha told a magazine for family businesses and entrepreneurs last year. “Essentially, they pulled our schedule ahead by nine hours in that one hour. This means they saved us $1,800 while rewarding themselves at the same time.”

The Visual Earnings System earned Humtown NAM’s Talent Management Leadership Award for unleashing human potential.

Luck favors the prepared. This year, Humtown Products was uniquely positioned to help customers manage challenges no one could have anticipated.

“Having the ability to develop tooling without visiting a customer location, we’ve seen an uptick in the ability of foundries to use this technology,” says Brandon, who’s director of additive manufacturing. “The pandemic has shown a lot of people that much work can be done remotely without being on-site.”