Safe Shops: Factory Operations During COVID-19

Manufacturers no longer wonder when the pandemic is going to be over, but how to profitably interact with customers and suppliers in a way that protects the health of employees, their families, and the local community. As ever, U.S. metal fabricators and machining companies are highly resourceful.

Posted: September 4, 2020

BY STEPHANIE JOHNSTON

Phoenix-based R&D Manco has been machining housings, oil jets, carriers, liners, shrouds, shafts, and fittings for aircraft, spacecraft, and military applications for more than 50 years. As a defense supplier, you’d think they’d be on top of things when rumblings about a new virus from China began circulating early this year.

And they were. General Manager Kevin Beach heads the company’s safety committee, which began taking action in February to keep the virus from disrupting operations. They identified common touch points throughout their 30,000-square-foot facility and developed a cleaning schedule. They made hand sanitizer readily available. They reviewed their continuity-of-operations/preparedness plan.

Then, one Thursday in June, an employee who just happened to be at a CVS Pharmacy that just happened to be doing free testing for SARS-CoV-2, the coronavirus that causes COVID-19, approached Beach at work. He said the results of the test – which had been done seven days earlier – were positive.

For seven days, that employee had been working around other employees. Although he’d known such a scenario was a possibility, Beach and his team were caught off guard. It didn’t take long for word to spread.

“I cannot tell you the amount of anxiety that went through the shop,” he told attendees of a July 15 National Tooling & Machining Association (NTMA) / Precision Metalforming Association (PMA) webinar. “There was a lot of panic because we’d all been around the person. It was something I’d never seen before.”

To stop the rumors and speculations, he called all 75 employees into a meeting to tell everyone all at once, in person, what had happened and figure out how to proceed based on Centers for Disease Control and Prevention (CDC) resources and employee concerns. They didn’t close the entire facility, but they shut down the area where the employee worked, bought a sprayer, and hosed down that area with a solution of bleach and water.

Looking back, Beach, who’s also president of NTMA’s Arizona Chapter and NTMA’s Manufacturing Technology Team lead, wishes the safety committee had planned a formal response to a positive test result. He has two pieces of advice: “Figure out exactly what you’re going to do when you get that positive. Research rapid-testing facilities near your area and if you find one, post it in your facility.”

In one way, R&D Manco is lucky: The company has just one location to worry about.

Heidenhain Corp.’s 200 employees, on the other hand, are in 12 regional offices across North America as well as headquarter locations in San Jose, Calif., and Schaumburg, Ill. Illinois was one of the first states to issue a stay-at-home order, which went into effect March 21. The biggest challenge for the manufacturer of precision-measurement and motion-control solutions was maintaining consistent, up-to-date communication in a crisis to which each state responded differently.

The company created a website to share information and answer employee questions about new government programs, such as the Families First Coronavirus Response Act (FFCRA). “Everyone calmed down and appreciated what the company would do for them,” Director of Machine Tool Business Development Gisbert Ledvon told webinar attendees. Other ways to maintain communication, per CDC recommendations, include creating and encouraging employees to follow a company-only Facebook, Twitter, WhatsApp, or other social media page. Text-messaging programs can automatically translate messages into languages other than English to reinforce company policies.

Heidenhain had plenty of sanitizer, gloves, and other supplies because its purchasing manager stocked up as it became clear how contagious and potentially deadly the novel coronavirus was. However, employees were no longer allowed to share PCs, requiring the company to buy additional equipment. Every morning, every employee gets an email with 10 questions, similar to what a doctor would ask during an office visit, to gauge their present state of health. If a questionnaire isn’t completed, the employee’s manager is notified and must contact the employee.

“Whoever thought going into this thing that you’d be worrying about what your inventory of toilet paper would be?” asked Erhardt Tool & Machine Vice President Patrick Walsh. The Granite City, Ill., manufacturer of precision, contract, tool, die, and special machines with 150 employees bought video equipment to perform virtual runoffs with customers who’d ordered machines. But toilet paper – that, said Walsh, is the type of thing the company’s considering as it revises its continuity plan.

“The better your plan, the better your reaction,” he told webinar attendees. “Write it down when it comes to mind, bring it to your team, and get it into your plan.”

The New Normal: Coexistence

As of early September, schools at all levels were moving to all-remote classes almost immediately after opening for the fall semester as clusters of outbreaks among students demonstrated how contagious the virus is. The U.S. has tested more people than any other country. However, at 14.3 tests per confirmed case, an indicator of the adequacy of contact-tracing programs, the U.S. ranked 15th globally on Aug. 28 (the World Health Organization recommends 10 to 30 tests per confirmed case). A vaccine may be available by the end of 2020, but multiple surveys show not all Americans will get vaccinated.

In mid-July, as part of their joint One Voice COVID-19 initiative, NTMA/PMA asked member companies about their finances, workforce, and business development. Only a minority had laid off or furloughed employees, and most hadn’t reduced wages or salaries. Most – 82% — also had no confirmed COVID-19 cases. However, 10 had at least one case and 10 had two to five cases. Three reported 11 to 20 cases.

Hopefully, with the measures that metal manufacturers have implemented, the numbers will stay low. Given the statistics, though, your company may have to deal with a case if it hasn’t already.

In April, a survey of members conducted by the Manufacturers Alliance for Productivity and Innovation (MAPI), a nonprofit professional society for executives at large, global industrial companies, showed that most felt adequately prepared to fully reopen all operations in June and July.

Virtually all – 90% – had developed and were documenting screening protocols (although standards differed from facility for facility for 46% of respondents). They’d developed and implemented return-to-work policies for screening, use of facial coverings and other personal protective equipment (PPE), social distancing, cleaning and disinfecting, workforce safety communications, telework, and travel restrictions.

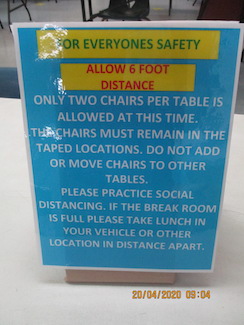

New work arrangements included reinstating employees in stages, rotating teams, staggering start times, and customizing hours and shifts. Almost 90% required 6 feet of distance between employees, and more than two-thirds planned to ban all visitors except deliveries.

In June, many were grappling with how to maintain quality controls in the midst of staffing reductions. Half were still doing in-person, in-the-lab testing; but nearly two-thirds expected to accelerate efforts to automate the process.

By July, these executives were predicting demand for their companies’ products would return to pre-pandemic levels only after a vaccine is developed. Four out of five reported increased investment in smart manufacturing technology. Many expected factory floor reconfigurations to become permanent – an exercise that, as NTMA President Roger Atkins, former vice president of Sales & Marketing for MIC Group in Brenham, Texas, who now advises small- to medium-sized contract manufacturing companies, is “a lot different for a desk than a machine tool that has to produce accuracy of 1/2000ths.”

The pandemic is also impacting employees’ emotional life.

In March, according to the American Psychiatric Association, one-third of Americans said the virus was negatively impacting their mental health. Even so, by July only half of MAPI members ranked mental as a top-5 priority despite how anxiety and depression increase absenteeism. In their defense, protections and confidentiality may obscure the problem’s magnitude. Per the federal Health Insurance Portability and Accountability Act of 1996 (HIPAA), employers may not share the names of infected employees.

Automation and Social Distancing

“When the pandemic hit, we were well-positioned to implement social distancing,” says Gary Kuzmin of his three Dallas-based businesses.

Kuzmin launched All Axis Machining Inc. in 2007 to provide OEM design companies with fabrication services and thermal management products made on equipment including 5-axis CNC machines, 11-axis combined milling and turning, and wire and sinker EDMs.

The company typically runs more than 20 different parts every day. In his never-ending quest to increase efficiency, Kuzmin looked into and rejected large-footprint, difficult-to-program industrial robots that couldn’t directly interface with his legacy equipment. When he found the flexible mounting options and open programming architecture of the Universal Robots+ collaborative robots (cobots) platform, he bought one UR10 at the end of 2017, three in 2018, and four in 2019.

Along the way, he and his team learned what it takes to equip the machines to automate CNC machine-tending, sanding, deburring, part inspection, laser marking, and wire EDM. Different operations require different grippers, some require special fingers to be machined, trays must be placed to collect parts, a cobot needs physical support. He estimates accessories and fixturing represent 20% of a cobot’s price.

Armed with this expertise, he started All Axis Robotics in 2019 to integrate turnkey UR cobot solutions for other fabricators. His third company supports that business by building cobot stands and other hardware. Altogether, the businesses employ almost 50 people.

When the pandemic hit, the cobots enabled All Axis Machining to increase production without a corresponding increase in overtime.

“We rejuggled everything,” Kuzmin says. Most employees work the day shift qualifying machines to run with minimal supervision by two employees working from 3 pm to 11 pm. The final task of those second-shift operators is preparing machines to run fully automated during the third shift from 11 pm to 6 am.

All Axis Machining makes many components used in respirators. When business increased because of the pandemic, the company added a fourth shift to run over the weekend staffed similarly to the second shift. Before those two employees leave, they set up the machine to run a completely automated fifth shift.

“This is how we maintained and reorganized production,” says Kuzmin. “When a second-shift employee tested positive, both workers had to self-quarantine. However, because that shift has minimal labor requirements, we just moved some first-shift personnel to staff that shift. We think we’ve created a model other companies can use to maintain throughput without compromising employee health.”

Sidebar 1

UPDATE: Manufacturer of the Year Outlines COVID-19 Response

See photos above.

METCAM President Bruce Hagenau was dealing with the coronavirus weeks before Georgia Gov. Brian Kemp ordered residents home as of April 3.

Hagenau co-founded the ISO 9001- and 14001-certified fabricator of precision sheet metal components and assemblies for OEMs such as Caterpillar, Carrier Corp., CommScope, and Tyco in 1989. In 2018, commitment to continuous improvement earned METCAM (an acronym for Metal and Computer-Assisted Manufacturing) three awards in its drive to lower rejection rates to 50 parts per million (ppm).

Hagenau leads the Next Generation Manufacturing of Georgia’s thought-leadership panel. On April 23, he shared METCAM’s pandemic-response experience during a webinar. He’d been working from home since February, having self-quarantined after experiencing COVID-like symptoms.

As of that date, one of the company’s 130 employees had reported mild symptoms and was sent home. The employee’s work station and those nearby were disinfected, and the health of employees in the work area was monitored. Confirmed positive on April 21, the second-shift employee must test negative before returning to work.

Orders were strong, so METCAM was running at full capacity even though about 30% of employees opted to stay home. The key to keeping it all together, said Hagenau, is constant communication and reinforcement. “Our objectives are threefold: ensure the safety of our employees, their families, and visitors to our facility; do our best to prevent virus spread; and continue to operate our business for the benefit of both our employees and our customers.”

Sidebar 2

Recording and Reporting Requirements

The Occupational Health and Safety Administration (OSHA) would probably consider most metal fabrication and machining companies to be among the lowest-risk employers. But regardless of risk, a confirmed case of COVID-19 is a recordable illness if it’s work-related (per 29 CFR Part 1904, such records are often referred to as an “OSHA 300 Log”).

Since determining that is more easily said than done, Graphic Products Compliance Specialist Brian McFadden recommends making a reasonable investigation to see if you can determine whether the transmission is likely to have occurred at work. For example, have there been cases among employees who work closely together? Could the employee have contracted the virus from a customer or supplier? The community at large? A family member? Consider information the employee can provide for you, as well as any information from local healthcare providers and public health authorities.

“Even if you determine it was work-related, that doesn’t necessarily mean your organization did anything wrong — but failing to investigate, or even hiding your findings, would be a problem,” says McFadden.

OSHA’s “COVID-19 Guidance for the Manufacturing Industry Workforce” can be found at www.osha.gov/Publications/OSHA4002.pdf.

“When in doubt, remember this guiding principle: Employers have a legal obligation to provide a safe workplace,” says McFadden. “This is the ‘general duty clause’ from the law passed by Congress 50 years ago that gave OSHA its authority.”