Marking Parts Is About More Than Just the Machine

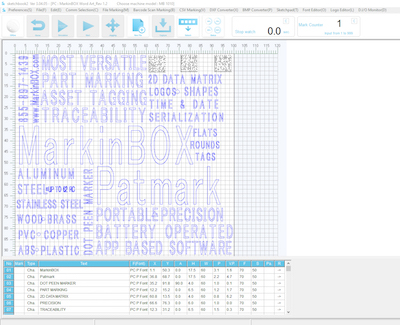

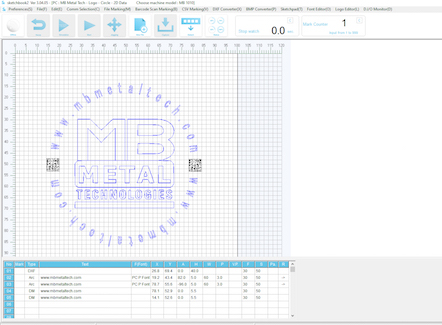

MB Metal Technologies’ Sketchbook2 software greatly simplifies the process of programming the company’s benchtop, fixed-mounted, integrated, and portable dot peen marking equipment. The user sees and can easily change text and logos before marking begins.

Posted: October 8, 2020

BY RYAN BRADY

I learned a powerful lesson three decades ago in my grandfather’s basement workshop as we turned some wooden bowls by hand on his lathe. When we were done, he turned to me and said, “You should be proud of your work. Put your name on it so people know who made this fine piece of craftmanship.” I felt immense pride in a job well done as I signed the bowl’s bottom with a permanent marker.

It’s a lesson I’ll never forget. Whether you’re a fabrication or metal cutting company, or both, you need to identify your products to the rest of the world. It could be a simple as adding a part number, serial number, or company logo to the part. Or it could be more advanced, such as adding a 2D data matrix for traceability as required by customers in industries like aerospace and health care.

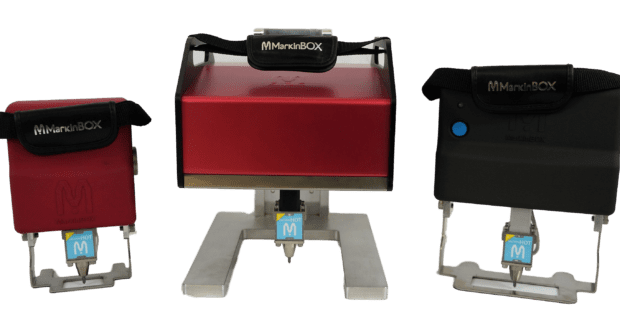

Milwaukee-based MB Metal Technologies LLC helps manufacturers of all sizes with this critical aspect of the production process via two fully electric dot peen marking systems. Both feature WYSIWYG (what you see is what you get) software that makes adding text and graphics virtually foolproof even for someone who’s never marked parts. Quick-change fixtures for marking round and cylindrical parts are available for both models.

Our goal is to demystify the process with an intuitive interface and tools that simplify programming of a wide range of marks.

With Multifunctional Marker, Imagination Is The Only Limit

The 120V MarkinBOX machine is available in four sizes and a myriad of setup configurations to tackle virtually any challenge that may arise in today’s ever-changing manufacturing landscape, whether it’s marking a part, a tag, a plate, a round, or a cylindrical part. Its Windows-based Sketchbook2 software provides a full suite of capabilities including alphanumeric characters, logos, serial marking, calendar marking, and 2D data matrix and QR code marking.

Users configure one or more lines of alphanumeric characters, the most basic mark, by adding text fields. The software default setting makes characters in “MB font,” an easy-to-read font designed for simple marking. Sketchbook2 also comes with a basic “5 X 7 font” for fast marking. Users can get creative by importing fonts from programs like Microsoft Word and Adobe Photoshop.

Logos are made in two ways. The software’s .DXF file converter automatically transfers lines into a marking file (.PPG); or, after uploading a .JPG file, the user creates the marking path by tracing the logo. The latter method takes a bit longer than the .DXF file transfer, but gives the user more control over how the logo will be marked.

The software’s 2D data matrix and QR code option links data fields to the data matrix or QR code to enable the user to store batch number, lot number, material type, manufacture date, or a link to a website or reorder point information within the code itself.

Serial marking enables the user to mark an up-to-8-digit number that increases by one digit each time the program is run. This saves time and money because users don’t have to set up a new program for each piece they’re marking.

The customizable calendar marking function also saves time by automatically adding day, month, and year.

A dashboard enables users to finetune the marking fields. In addition to determining the mark’s starting point by adjusting the X and Y axes, you can adjust character height and pitch, use the electromagnetic control on the marking head to change how much force is used, and adjust the speed (also referred to as quality, or number of dots, used).

All these controls enable marking of a wide variety of metals including aluminum, brass, copper, stainless steel, steel, and hardened metals up to 62 RC.

The MarkinBOX can be automated to increase efficiency by integrating marking into the production process.

A Mobile Marking Solution

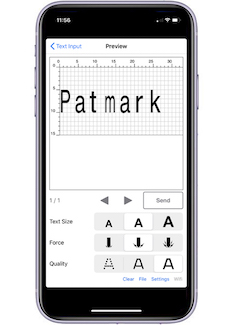

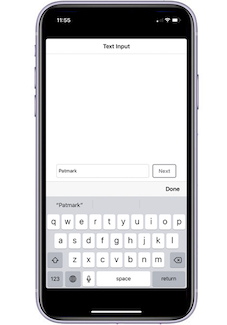

Released in 2018, the hand-held, battery-powered (25.2V) Patmark 1533 and Patmark Mini’s Windows-based software looks, feels, and works very much like Sketchbook2. However, the units also enable users to download a programming app on an iOS or Android smartphone to mark up to one line of alphanumeric characters. A Wi-Fi chip in the unit establishes a connection between the phone and the marker, eliminating the need for a laptop for programming.

The app opens with the Text Input screen. The user inputs marking text and clicks Next. The app then takes you into the Preview screen that, because it’s WYSIWYG software, shows the user what the mark will look like. Text size, force, and quality can be adjusted from the preview screen. Once satisfied with the layout, the user clicks Send and the app wirelessly transfers the marking program directly to the unit. The user lines up the unit onto the item to be marked, pulls the trigger to take the marking pin to the start position, and pulls the trigger again to initiate marking. It’s that simple.

Customers can reach our team of support technicians for step-by-step guidance via a toll-free support line. We also offer virtual online meetings via GoToMeeting where our technicians coach customer employees through the entire marking process.