GMTA Offers Stiefelmayer Lasers In North America

German Machine Tools of America (GMTA) buttresses its line of machines for U.S. power train manufacturing by representing Stiefelmayer GmbH fiber and diode laser machines for cutting and hardening. The machines are particularly well-suited for the thin components required for electric vehicles.

Posted: December 28, 2020

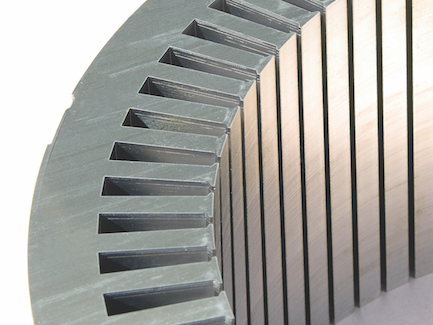

German Machine Tools of America (GMTA) (Ann Arbor, MI) is representing the full line of Stiefelmayer GmbH (Denkendorf, Germany) machines in North America. Electrical-optical efficiency of approximately 30 % and outstanding beam quality enable the Stiefelmayer laser to cut precision shapes in thin substrates such as mild steel, stainless, copper and brass. Motor laminations are a particular specialty, making the machine excellent for producing components for the U.S. electric vehicle industry.

The machine’s Y axis and attachment parts are made from lightweight carbon to increase speed and efficiency. Virtually wear-free X/Y-axis linear motors ensure cutting path accuracy with a straight movement that minimizes vibration.

The 1 kW Stiefelmayer effective S features a 1,250-mm-x-1,250-mm cutting table. Axis paths: 1,260 mm (X), 1,260 (Y) mm, 50 mm (Z).

The Stiefelmayer effective L (1 kW and 2 kW) has two adjacent tables with three-sided access to enhance flexibility. One 1,250-mm-x-1,250-mm table with completed parts can be moved out, unloaded, and reloaded while the other table moves into working position. Coupling the tables achieves a table size of 2,500 mm x 1,250 mm.

Featuring high feedthrough and long Z axes, the Stiefelmayer effective M is a cost-effective alternative to 5-axis 3D processing for many tasks. Designed to cut formed components or parts in fixtures as well as sheet metal and material strips, it offers a table size of 1500 mm x 1500 mm and large sliding doors for convenient access. The table can be extended to facilitate loading and unloading of parts.

Stiefelmayer’s blue effective energy-saving technology lowers the machine’s carbon footprint and saves customers money.

www.stiefelmayer-lasertechnik.de/en