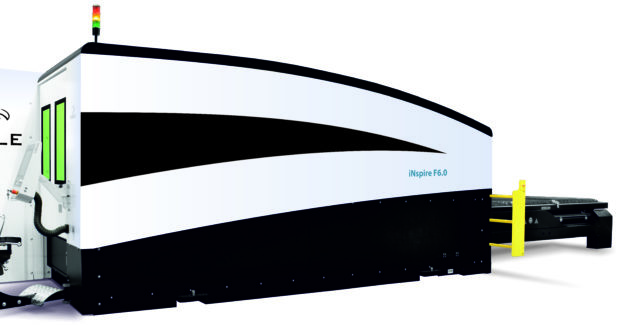

High-Speed, High-Power Fiber Laser Available in U.S.

Seattle-based Fairmont Machinery is importing, distributing, and servicing Power-Tech’s Eagle laser cutting systems. The Polish machine tool builder’s products are available with 6, 12, 15, and 20kW of power.

Posted: December 28, 2020

Eagle brand fiber laser cutting systems manufacturer Power-Tech (Walcz, Poland) appoints Fairmont Machinery (Maple Valley, WA) as U.S. master distributor responsible for sales, service, and parts. Fairmont Machinery spans the country from headquarters near Seattle and an East Coast office near New York City, ensuring Eagle customers get highly trained local support.

Available in 6, 12, 15, and 20kW power levels, Eagle laser cutters feature 6G acceleration, automatic loading and unloading solutions including 9-second pallet exchange, brand-agnostic nesting and control software, and options including a heavy-duty package.

Designed for metal laser cutters using laser fiber source technology, the auto-focus and -centering eVa cutting head is easy for operators to maintain.

Auto-focus eliminates the need to manually adjust the focus distance based on material type and thickness, reducing setup time and eliminating potential errors. Automatic centering acts as an anticollision system by not allowing the beam to be emitted when not centered. As a result, the entire head and components such as the nozzle and sensor are protected against damage, significantly extending service life. This solution also reduces the number of expensive wearing parts in the head, such as ceramic parts or adapters.

The cutting head provides four levels of anticollision protection. First, the capacitive nozzle sensor avoids low-speed collisions. Next, the head slides laterally to give the machine time to stop. Both are resolved in seconds via automatic nozzle centering.

At very high speeds, the cutting head rotates on springs to save the lower module. Finally, at full traverse speed (over 100m/min), the lower module breaks away to avert significant damage. The system is brought back into operation in less than 1 hour by screw replacement.