Broken-Tool Monitor Doesn’t React to Nuisance Faults

Allora International’s PCS-100 sensor kicks in only when a drill, tap, reamer, or end mill breaks, not when chips are accumulating; and ignores common tool-to-tool diameter differences. Speeds exceed 80 cycles/minute to keep up with the fastest machines.

Posted: January 17, 2021

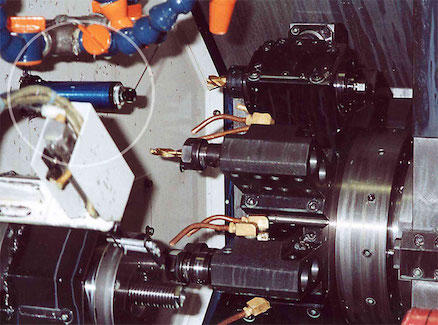

Designed to check cylindrical shank tools such as drills, taps, reamers and end mills, the PCS-100 broken-tool monitor from Allora International LLC (Waukesha, WI) is mechanically adjustable so users can easily set or change the sensing needle sweep from 5 to 175 degrees in the clockwise (CW) or counter-clockwise (CCW) direction. A direct-drive DC motor eliminates the need for a miniature reversing gear box that’s subject to wear and tear. And, at speeds exceeding 80 cycles per minute, the sensor keeps up with the fastest machine.

Setup is simple. After mounting, set swing angle and direction using the patented adjustment feature. Flick control’s selector switch to correspond with CW or CCW swing direction. If the 5.5-inch (140 mm) Maxi Life sensing needle (other lengths available) travels to its end, indicating a broken tool (or missing object), a fault output is generated, causing the machining to stop or to be put in a feed hold.

The control unit monitors setup, and will indicate a fault if the user incorrectly set swing direction or if electronic failures, such as a cable disconnect or short, occur between the PCS-100 positive-contact sensor and the SCU-100 sensor control unit.

The system faults only when the tool breaks, helping avoid expensive nuisance faults in many applications – for example, where you don’t want the machine to stop until a chip nest and tool break away rather than while the chip nest is accumulating. The system is also great for CNC lathes or machining centers because it ignores common tool-to-tool diameter differences.

The system can be used to monitor free space rather than object presence. Moving the selector switch on the sensor control unit to “RL” sets the system to operate in reverse-logic mode, so a fault is generated only when there’s an obstruction.

Required voltage: 24V DC (250mA); optional 110-240VAC power supply available. Separate ok and fault “dry contact” relay outputs are each rated at 2A, 250V AC. Mount via incorporated 35mm DIN rail connector or by using the two mounting holes.

A PCS-100-AP (air pressure) is available for extreme cutting tool environments.