Digitizing Your Welding Operation Could Be the First Step to Higher Overall Throughput

A factory has many moving parts and processes. Connecting welding data to up- and downstream processes makes identifying the source of manufacturing problems easier and uncovers true costs across the entire operation.

Posted: January 28, 2021

WELDING TIPS COLUMN

BY JASON DUNAHOO AND JASON BONNELL

Do you know which areas of your operation are the most productive? Are you struggling to control costs? Are quality issues making their way into the field and to your customers? Do you know if improvement efforts are working consistently?

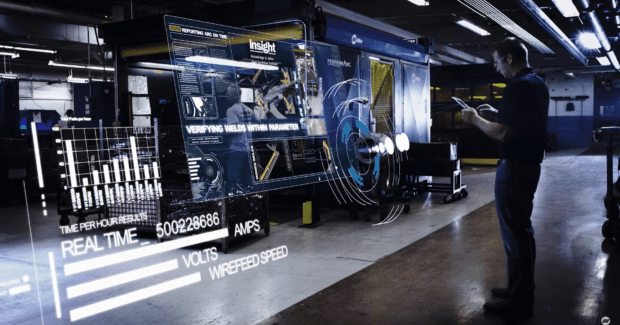

Digitization can answer all these questions and help your company stay ahead of the competition regardless of what you make and how large or small your operation is. In a digitized manufacturing environment, data, documents, and processes previously tracked by hand, often on paper, are digitally tracked — in some cases, automatically by the system. In addition, systems throughout the operation can be linked to provide a full picture of the manufacturing process, often in real time.

Welding is just one part of a digitized operation, but significantly impacts other areas of the manufacturing process and potential improvements. Therefore, having visibility into what’s happening in each weld cell is critical to improving quality and throughput in the entire operation.

If you’ve decided digitizing is right for your company, these six tips can help you optimize the process and the results.

Tip 1: Start With Small Steps

Jumping right into the deep end of digitizing isn’t the best first step, especially for manufacturers that haven’t digitized processes before.

Start with small steps to figure out what works best for your operation, then progress to larger and larger pieces over time. Rather than digitizing the entire factory, start with one production line or one area of the plant.

Start with operations that have a lower barrier to entry in terms of cost. Digitize the welding operation first, followed by the cutting area and then the stamping operation, for example.

Tip 2: Establish The Baseline

You can’t control what you don’t measure. Establishing a baseline allows manufacturers to figure out where they are and what they want to measure — which in turn allows them to track and control those metrics over time.

When an operation wants to improve productivity, it must start by measuring all the factors that make up productivity.

Look for arc data-monitoring software that can provide baseline data and visibility into your welding operation. Measuring each welder’s arc-on time allows you to establish a productivity baseline for your operation, make plans for improvements and measure your progress toward goals. Dashboards allow you to identify important trends and develop reports with data you can analyze, allowing you to take action.

Tip 3: Let The Data Drive You

You may start with the hypothesis that you have a welding productivity problem. However, once your digitization solution is in place, the data may show that your welders are regularly waiting on parts. The answer might lie in changing the line layout or increasing the speed of cutting and bending operations. Looking upstream and downstream of the weld cell can uncover other bottlenecks or issues.

A digitized weld cell is just one part of the overall operation — the problem or answer may not always be found in the weld cell. Data gathered in the weld cell can help operations figure out what questions to ask about the entire operation.

With an advanced welding intelligence system like our Insight Centerpoint, for example, operators track activity and tell the system when they’re waiting for parts or there’s a holdup on the line. Over a week or a month, the company can see how many hours per day operators are sitting idle and justify proposed improvements they make to the entire operation.

Perhaps it’s better to bring preassembled parts into the upstream process, add equipment such as another cutting table or outsource a certain task somewhere along the line.

Making data-driven decisions helps ensure you’re tackling the right areas to fix problems and optimize results at all stages in the process.

Tip 4: Document Product Workflow

Many manufacturers are dealing with labor shortages, so the expertise of operators on the production floor will vary. Some operators may have 30 years of experience and know the precise steps that go into building a part, while others are new to the company and still in training.

Documenting every step in the workflow helps ensure proper procedures are always followed to produce consistent quality as operators change.

Insight Centerpoint can guide operators through the weld sequence in real time. This reduces training time and helps ensure consistent, high-quality parts.

Documentation of the workflow is a step that likely won’t happen frequently. You document the workflow once and — unless the process changes — it doesn’t need to be done again.

Tip 5: Confirm The Results

You’re gathering data and using it to make changes — that’s good. Now these steps must be followed up with confirmation of the results.

Trying new solutions in an effort to yield improvements is important, but making sure those solutions actually work is what closes the loop on the process.

Using the same tool throughout the entire digitization process in the welding operation — from measuring the baseline to confirming results — helps streamline this process.

Tip 6: Attack The Next Thing

Continuous improvement is just that — continuous. Using data to guide improvements doesn’t happen just once. It’s a “rinse-and-repeat” process you undertake multiple times.

Appointing someone in the organization as the champion of these efforts helps ensure the ball won’t be dropped and that your operation continues to run at peak performance.

The fifth and final step of the 5S management strategy is “sustain,” as in sustained discipline of improvement efforts. The responsibility for this step should be shared between management and the workforce.

Leverage Welding Intelligence Solutions

Digitizing the welding operation with welding intelligence solutions and connecting it to the overall enterprise improves product quality, provides better traceability of problems, and offers an understanding of true costs across the entire operation.

A manufacturing operation has many moving parts. Integrating the processes with a data-centered approach helps companies uncover improvements so they can reach their goals.