How to Become a Multipass Welding Master

Multipass welds are often required in pipeline, ship, heavy-duty structural and pressure vessel construction. Selecting the proper abrasives and cleaning properly between each pass can help optimize results, saving the operation time and money.

Posted: February 2, 2021

SURFACE CONDITIONING COLUMN

BY RON MCCARTHY

Multipass welds are necessary in many applications to join butt welds in the same plane that have a gap or bevel, including welds used in heavy-duty structural, process pipe, pipeline, shipyard and pressure vessel industries. Adding layers of weld to thick metal joints increases the strength of critical welds where testing is often required and weld failure could be catastrophic.

Each pass much be thoroughly cleaned before the next pass is laid down to ensure there are no inclusions that would cause a weld to fail inspection — or worse, fail in operation. Therefore, the abrasives and wire brushes used for grinding and cleaning between passes play a critical role in the quality of the finished weld.

Challenges of Multipass Welding

The most important step in successfully producing high-quality multipass welds is to make sure each pass is clean and free of inclusions. Otherwise, weld defects such as porosity can be introduced, and these impurities can prevent welds from passing inspection. Repairs are costly, so time spent cleaning on the front end is saved at the finish.

Starting with the base material, be sure to remove mill scale and any dross or slag that results from plasma cutting. Then, you must clean each pass as you go. After the initial root pass, grind the weld down to create a U shape. Be sure to grind through any impurities that have bubbled up. The root pass should be cleaned with a 1/8-inch grinding wheel. The wheel must fit into the gap or bevel.

The cleaning of the hot pass and subsequent fill passes is typically done with a power wheel brush, especially when stick welding because it produces a slag. Depending on the application, it may also be necessary to clean or dress the cap pass if you will be painting or coating the weld.

The most important factors with multipass weld cleaning are simply taking the time to do it – and do it properly.

Choosing Abrasives For Multipass Welding

Size is one of the most important considerations when choosing the proper wheel for grinding the root pass.

You must be very careful to avoid grinding out too much of the bevel or ruining the weld penetration. A 1/4-inch grinding wheel would be too large and remove too much of the bevel. A 1/8-inch wheel is a better size for grinding the root pass.

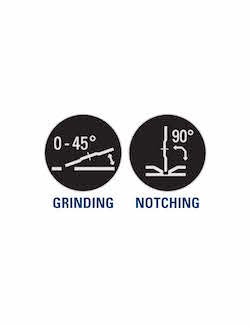

Be aware that not all 1/8-inch wheels are designed for grinding at various angles. Grinding on the root pass is done at a 90-degree angle. If it’s necessary to perform tasks beyond vertical grinding, such as grinding bevels or facing lands, look for a wheel with extra reinforcement so it can be safely used at 90-degree and 45-degree angles. Some 1/8-inch grinding wheels have three layers of fiberglass that hold the product together and allow it to be used for more than vertical grinding.

It’s also important to choose a wheel specifically designed for multipass welding and grinding hot welds. Running a standard grinding wheel over a hot root pass can result in wheel loading and eventual glazing. In response, operators may modify or cut a chip into the wheel, which is a safety hazard. Using a wheel designed for multipass welding reduces chatter and glazing while offering superior cut and life — without having to chip the wheel.

Choosing Wire Brushes For Multipass Welding

Cleaning the hot pass and fill and cap passes generally requires using a power wheel brush. There are numerous brush designs, and each one offers benefits depending on which weld pass is being cleaned.

Stringer bead brushes are twisted the entire length of the wire. Also called buffing wheel, these brushes are 1/8-inch wide, making them ideal for cleaning the hot pass, which tends to be lower in the bevel and therefore a tight space.

Dually stringer bead brushes allow operators to flip the wheel around, bringing wire points back to the workpiece. As a brush is used, the wire points wear on an angle away from the workpiece. Dually brushes have an additional nut on the wheel so operators can easily flip them, allowing the brush to remain at its most aggressive performance level throughout its use.

Standard twist brushes are twisted at the bottom but not the top of the wires. These wider brushes are often used to clean the cap pass. With each subsequent welding pass, the bevel gets wider, so using a wider brush can increase cleaning efficiency.

Cable twist brushes have wire twists that are closer to the ends than standard twist brushes, but not all the way to the end like stringer bead brushes. Cable twist brushes can be used for wider fill and cap welds, as they are more aggressive than the standard twist but offer a larger wire surface than a stringer bead.

Encapsulated brushes are wire wheels encapsulated with an elastomer that holds the wire together, exposing the wire tips. The wire is held firm by the elastomer, reducing the trim length and making this brush type the most aggressive available. Because the wire is encased, breakage is reduced and it can be a safer tool. The elastomer also extends wheel life.

It’s important to consider the base material when choosing a power wheel brush for weld cleaning. If the base material is stainless steel, use a stainless steel or aluminum wire brush to avoid cross-contamination. If the base material is carbon steel, choose a standard carbon steel brush.

Three Best Practices For Cleaning Multipass Welds

Once you’ve got the right product for the job, there are some common best practices that improve results when cleaning multipass welds.

Watch out for glazing. Glazing is a very common problem when cleaning multipass welds with a grinding wheel. The root pass is always ground when hot, so choose a disc that’s formulated to resist the added heat.

Pressure creates additional heat that increases the chance of glazing. While a harder bond has a longer product life, it won’t cut as well because the resin doesn’t dissipate to expose the grain. A harder bond also requires you to put more pressure into the cut, increasing heat buildup. A softer bond cuts much faster but doesn’t last as long because the resin exposes the grain and dissipates rapidly.

Look for a wheel with a high-quality — ceramic, zirconia or aluminum oxide – grain to increase cut rate without glazing.

Avoid using too much pressure. Using too much pressure with an abrasive product can affect product life, cut rate, safety and operator fatigue.

As I just mentioned, too much pressure on a grinding wheel increases heat buildup and can result in glazing. It can also gouge the material. A light touch is especially important when cleaning the root pass, where scarring the bevels and removing too much of the root can cause issues in weld inspection.

Proper pressure is also important when cleaning with a wire brush.

Because the tips are designed to do the work — like small hammers pinging the weld — using too much pressure can bend the wires. This reduces brush aggression and performance and can cause wire breakage, which is a safety hazard. If you’re not getting the performance you want, change the brush to one with more knots or different wire gauge.

Always use proper personal protective equipment (PPE). It should go without saying that proper PPE, including a face shield, gloves and all necessary product guards, should always be used in grinding and cleaning applications. Completing a task faster doesn’t benefit the operation if it risks operator safety.

Evaluating And Managing Consumable Spend

Consumables such as abrasives and brushes for multipass weld cleaning and grinding can be measured in life cycle, safety and production. Tracking and understanding their use can help operations save money. Data that is measured can be repeated, and repeatability is the first step toward controlling consumable costs.

Therefore, it pays to develop a method for tracking abrasive and brush usage. Working with a manufacturer can help. Our Consumable Productivity (WCP) program, for example, helps companies conduct a study that encompasses product viability and productivity through the product life cycle. The analysis provides hard data about how a product is used, how long it lasts and how productive it is.

Testing at the facility helps establish a baseline, which is followed by collecting data and establishing averages through product evaluation. After reviewing the findings, you can create an actionable plan. A participant recently generated $70,000 in annual savings through testing and then tracking consumable data.