Gear-Cutting Shop Hops Hurdles With Tool-Holding Investments

A woman-owned Massachusetts company solved its feed and speed struggles with conventional side-lock and collet holders by turning to HAIMER shrink fit products. Short projection length with the Ultra Short Power Shrink creates more rigidity, and the Power Mini helps operators handle hard-to-reach areas.

Posted: March 12, 2021

Boulevard Machine & Gear was founded in 1954 as a family-owned gear cutting shop because of its location in the Pioneer Valley of Massachusetts, which was the hub for the paper industry. Over the years with various family members in charge, they transitioned over to primarily serving the aerospace and defense industries. In 2006, Susan Kasa acquired the company and transformed Boulevard Machine & Gear into the versatile manufacturing facility it is today.

While Kasa’s focus was to grow the company and make it even more efficient, Boulevard Machine started having trouble completing some jobs with its conventional side-lock and collet holders. They reached out to Jim Roberts, sales engineer at Lindco Springfield, to see if he could guide them to a solution.

“Boulevard wanted to run more accurately with tooling and extend tool life,” said Roberts. “I recommended Boulevard take a look at the HAIMER product offering.”

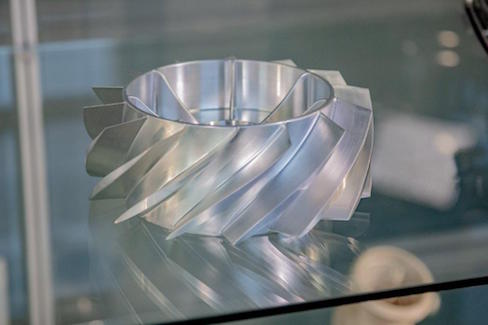

After seeing some of the benefits firsthand, Boulevard Machine decided to take the plunge and invest in a HAIMER Power Clamp Special Edition shrink fit machine, HAIMER Standard Shrink chucks, HAIMER Power Shrink chucks and extensions with the help of Mike O’Connor, regional sales manager at HAIMER USA. HAIMER develops inductive shrink fit technology for tool holders – based on its high gripping torque and clamping 360 degrees around the cutting tool, shrink fit technology provides better gripping torque, allows for excellent runout accuracy, balance repeatability and consistent clamping.

Boulevard Machine now has a wide assortment of CAT40 and HSK-63 holders in both Power and Standard shrink and all of the extensions. Since switching to the heat shrink holders, Boulevard Machine has been able to pick up its feeds and speeds, as well. Operators were able to cut 750 inches per minute with the ¾ inch HAIMER Ultra Short Power Shrink HSK-63 holder. Before HAIMER, they were limited to 300 inches per minute in the same material.

“We have more than doubled our feeds with the HAIMER Ultra Short Power Shrink,” said Kristian Kasa, CNC programmer and machine operator at Boulevard Machine & Gear. “It’s our go-to holder for roughing. It keeps our projection length short, which gives us much more rigidity than a conventional side lock or milling chuck.”

The shop is now doing as many five-axis jobs as they do three- or four-axis, whether its three plus two or five simultaneously. The HAIMER Power Mini shrink fit holders and shrink fit extensions helped get to all the hard-to-reach areas without any concern.

“We’ve had extensions stacked into HAIMER basic holders with more than 10 inches of projection with as little as two tenths runout,” said operator Kasa. “Without these holders, we would not be able to machine a large amount of the jobs through the shop.”

Reinvesting For The Team

For Boulevard Machine, it was an easy decision to purchase and invest in HAIMER technology. When Susan Kasa acquired the company, she decided to modernize it by reinvesting about 20%-30% of its yearly revenue back into capital equipment. Her reasoning: Innovate for the current workforce and for the next generation of machinists joining the team.

“We work closely with our programmers and engineers to make sure that what we are implementing and using is making their jobs as easy and efficient as possible,” Kasa said. “Having the HAIMER technology and staying up-to-date with everything else, our team is no longer hesitant about quoting or taking jobs and they have the confidence to do any task because of the sophisticated technology.”

Like HAIMER, Boulevard Machine keeps employees front and center while also striving to produce high quality products every time.

Following its successful implementation of HAIMER and other technologies, Boulevard Machine quickly outgrew its footprint and moved to a larger, state-of-the-art facility in Westfield, Mass.

“It really has increased productivity and energized the employees to be in this bright, new building,” said president Kasa. “We have even hosted visits for people who are interested in the HAIMER technology. Honestly, a lot of our success has come from collaboration, especially between us, Lindco Springfield and HAIMER.”

Kristian Kasa added, “I would recommend HAIMER to anybody who might not even be struggling. Just test it and see how much more you can push your machine and increase productivity.”