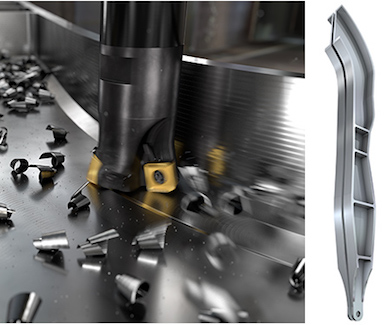

Cost-Efficient Small-Diameter, High-Feed Face Milling Cutter

Four-edged inserts help Sandvik Coromant’s CoroMill 415 face milling cutter reduce cost per component and increase productivity via a high metal removal rate. An E-M30 geometry complements M-M30 geometry assortment.

Posted: April 10, 2021

An E-M30 insert geometry for Sandvik Coromant’s (Fair Lawn, NJ) CoroMill 415 small-diameter high-feed face milling cutter delivers reliable performance in pocket machining applications. It also provides improved stability and controlled insert wear on the radius in helical interpolation and shoulder milling applications. The geometry is designed with a stronger radius for high security around the corner.

In addition to making the small inserts easier to handle, the milling cutter’s iLock secure insert seat results in fewer scrap workpieces. The versatile tool is suitable for a wide range of applications. Coolant channels optimize chip evacuation.

CoroMill 415 can be combined with the Coromant EH coupling and Silent Tools damped adapters for vibration-free machining, high reliability and a significant productivity gain.