Fully Automated Material Handling with ‘One System Fits All’ Module and Cobot-Armed Gates

The QM180 top module from Nord Modules increases the utility of autonomous mobile robots (AMRs) by connecting with a cobot-powered gate to create the first fully autonomous material-handling system. It also handles half pallets, plastic boxes, carton boxes, and carts without changing top modules.

Posted: April 19, 2021

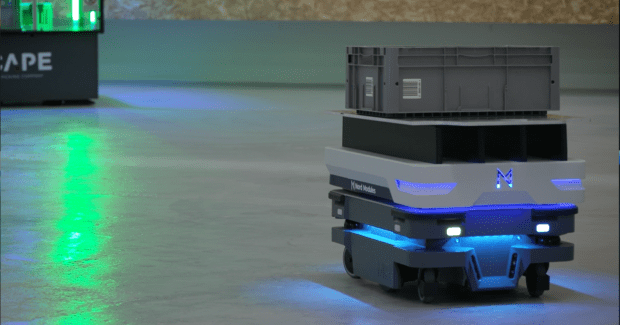

While autonomous mobile robots (AMRs) transform increase efficiency and reduce employee injuries, their benefits are only maximized with top modules and gates that transfer the materials. When coupled with the company’s automated load-transfer gates with collaborative robot (cobot) arms, the Quick Mover 180 (QM180) from Nord Modules (Odense, Denmark) creates the first fully autonomous material handling system, with material flowing seamlessly from production lines to the AMR to the warehouse.

For the first time, customers can use one top module to move materials to a cobot-armed gate that autonomously picks up and move multiple types of materials including half pallets, plastic boxes, carton boxes, and carts. This flexibility gives manufacturers the ability to move multiple container types from A to B to C, pick up goods from gates and deliver to a drop-off point, and precisely reposition goods to another automation area (e.g., a CNC machine).

The QM180 transports materials to gates installed at production lines, storage systems and conveyors. Docking time is reduced because sensors guide connection at the gates. The gates can include Nord’s CT155 (cobot tower), with an attached cobot arm that picks up the materials and places them where they need to go next. With this one-system-fits-all strategy, material handling becomes much less expensive because the AMR doesn’t have to be refitted with various top modules to transport and deliver different kinds of containers.

Before the launch of Nord Modules in 2018, top modules and gates were custom-made, requiring custom engineering, safety approvals, production and testing before they could be deployed. Nord develops standard robotic applications for load transfer that are space-efficient, highly flexible, and quick to deploy. Customers usually install top modules and gates out of the box within 30 minutes.

The QM180 integrates with Mobile Industrial Robot’s (MiR) MiR100, MiR200 and MiR250. It’s delivered with integrated software and a tablet for manual control. Users can also use the touchscreen to manually control the robot and adapt the system for specialized work processes.

Footprint: 31 by 24 inches.

https://www.youtube.com/watch?v=7CQZV1QuIC8