Plug-and-Play IIoT Platform Enables Digital Transformation

Attention mid-sized manufacturers: FactoryEye from Magic Software brings the digital world to you – with real-time intelligence – in an easy, affordable and flexible solution. No need to replace existing equipment or infrastructure.

Posted: April 27, 2021

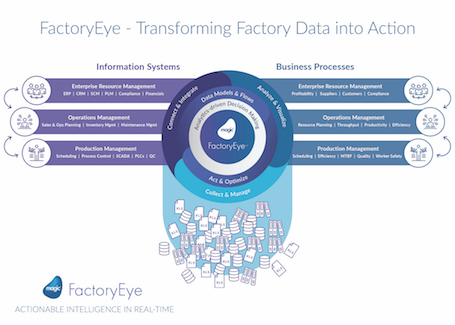

FactoryEye (Laguna Hills, CA), powered by a dynamic IIoT platform, collects real-time data from existing machinery and operational systems and transforms it into actionable intelligence for immediate results and continuous improvement in the manufacturing process. Magic Software Enterprises Ltd. (Or Yehuda, Israel) a global provider of end-to-end integration platform solutions and IT consulting services, has introduced the technology to North American manufacturers.

The solution brings the benefits of Industry 4.0 connectivity to mid-sized manufacturers in several industry verticals, including automotive parts, food and beverage, medical devices, metal processing, packaging, plastics & rubber and specialty manufacturing.

FactoryEye leverages Magic Software’s four decades of industry knowledge, integration technologies and deployment of mission-critical systems to thousands of companies around the globe.

With pre-established integration partnerships with leading ERP, CRM and PLM vendors and advanced analytics, FactoryEye ensures that key performance indicators are continuously monitored and reported in real time with cross-company data visibility.

“FactoryEye is unique because it brings the digital world of Industry 4.0 to mid-sized manufacturers in an easy, affordable and flexible solution without the need to replace existing equipment or infrastructure,” said Jack Klein, JKlein & Associates, a leading manufacturing consultant. “This game-changing solution works with current systems, connecting all the disparate parts under one platform. Now, mid-sized manufacturers can realize the benefits of greater visibility and actionable intelligence to keep their operations agile, efficient and competitive in any market conditions.”

Manufacturers in Europe and Asia are already realizing the advantages of FactoryEye’s unique capabilities to transform their work processes. SANHA group, a global manufacturer of press fit piping systems for water, gas, solar, heating, cooling and sanitary applications, chose FactoryEye as its Industry 4.0 solution to simplify factory floor production, minimize errors across the entire supply chain and improve production visibility.

“The move to Industry 4.0 makes sense,” said Andreas Jüsgen, CIO of SANHA. “It will help us connect devices with machines and set up digital processes. Automation enables machines, devices or transport units to follow a defined process without human input. By modernizing our production processes, we will increase production efficiency and streamline workflows in all of our European sites.”

FactoryEye’s end-to-end solution incorporates several key features:

- Powered by our plug and play IIoT Integration platform.

- Collects data from automated and semi-automated machines.

- Incorporates advanced analytics and AI into decision support.

- Customer KPIs are used to measure and qualify results.

- Leverages investments by integrating existing systems.

In addition to offering a dynamic cloud-based software solution, FactoryEye manufacturing consultants work with customers to harmonize their systems and fit the right tools for their needs. Consultants analyze business processes for what is working, formulate a plan to add what is missing from existing systems, and create sprints to deliver immediate results. A dynamic cycle of data collection and analysis allows for continuous improvement and flexibility in the optimization process.

“We designed FactoryEye to help mid-sized businesses compete and deliver new performance levels by enabling, connecting, analyzing and delivering up-to-the-second data, for robust, informed decision-making,” said Terri Ghio, president, FactoryEye North America. “FactoryEye is an affordable Industry 4.0 solution for mid-sized manufacturers that transforms data into actionable intelligence and provides visibility from the shop floor to the top floor, in real time. We are working with some of the top partners in the industry to make this a reality.”

www.magicsoftware.com/factoryeye