Surface Measurement for Non-Metrologists

OmniSurf3D from Digital Metrology Solutions helps users understand and communicate about surface texture without requiring a great deal of mathematical interpretation or metrology knowledge. The software provides the ability to interact with data from virtually any surface measurement instrument.

Posted: April 10, 2021

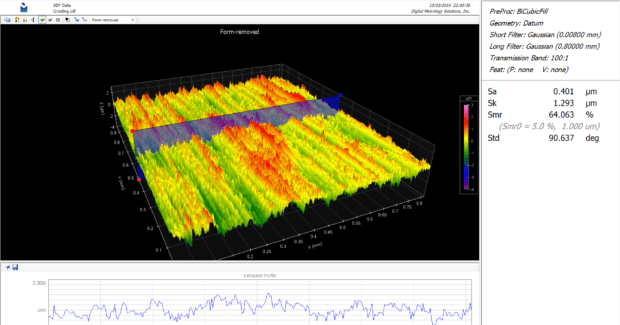

Most software available for analyzing surface texture is designed to acquire data from a single measurement instrument and produce parameter values as results. Instead, OmniSurf3D software from Digital Metrology Solutions Inc. (Columbus, IN) analyzes and visualizes surface texture in three dimensions, providing a suite of tools that can be quickly mastered by non-metrology experts to better understand the effect of surface texture on a part’s function. It gives machinists, line engineers and managers a toolset to visualize surfaces as well as calculate and report texture parameter values. The result is a more thorough picture of 3D texture and analysis, showing the connections between texture and function that can only be gained by seeing and interacting with the data.

The software shows how each data-processing step affects results. It guides the user through removing overall shape to reveal surface texture, filtering the data to highlight larger-scale waviness or finer-scale roughness and other processing steps. Interactive tools let the user zoom, rotate, cross-section and filter data in real-time and record animated views for output to presentations.

Beyond the visualization controls is a robust set of quantitative measurement tools. ISO and custom parameters are available to describe critical surface aspects. Advanced functions include pit and porosity analysis, wear analysis, plateau honing analysis and interactive filtering.