Glebar Offers New Centerless Form Grinder for Increased Throughput

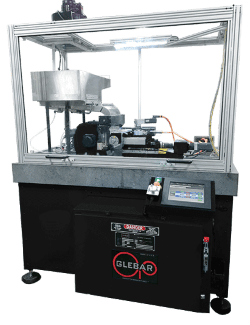

Glebar has launched the latest model in its series of plunge grinders, the new PG-912DG enclosed centerless form grinder.

Posted: June 1, 2021

Glebar (Ramsey, NJ) designed its new grinder to increase throughput via a 12″ wide work wheel. The wider work wheel allows manufacturers to grind more material or parts per cycle. In testing, Glebar’s engineers were able to increase throughput by as much as 30 percent.

The PG-912DG is also designed to reduce setup times, achieve tighter tolerances, and provide better integration to gauges, automation, and remote service diagnostics.

Setup time is reduced by pairing the wider work wheel with an oscillating regulating wheel powered by servo motors. The slides can be programmed to finite positions through a touchscreen HMI. When an operator selects a job, the servo motors automatically adjust to programmed positions, reducing setup time.

The work wheel and regulating wheel also improve sphericity.

“The position of the regulating wheel is critical to the accuracy of the grind,” said John Bannayan, Glebar’s CTO. “Using servo motors to position the regulating wheel creates greater repeatability in the grind and can maintain a tighter tolerance. In testing, we were able to achieve a Cpk two times greater than the existing process.”

In this specific application, a stainless-steel hopper automatically drops parts into the feeder channeling them into singular stations on the plunge grinder. Within a 14-second cycle, up to 12″ of parts can be ground simultaneously. The servo-powered oscillating regulating wheel assembly rotates the balls randomly, improving sphericity.

An interlocking safety enclosure and mist collector provide a safe, clean work environment. The granite machine bed helps to provide enhanced rigidity as well as thermal and vibratory stability. The high-speed, multi-axis control system can expand machine functionality and includes the ability to remotely diagnose the machine and gather production data for reporting.

Glebar provides precision cutoff and grinding machines and serves various industries, including medical, aerospace, automotive, industrial, consumer products, energy, and mining.