Don’t Overlook the Most Important Piece of the ER Holder Puzzle

It turns out, nuts are the most important pieces in ER collet systems.

Posted: July 8, 2021

DEPTH OF CUT

BY ALAN MILLER

It’s hard to argue with referring to the ER style as the world’s default collet chuck holder system. It’s an open standard anyone can make and they’re relatively inexpensive. They’re highly accurate and excellent for drilling, yet versatile enough to handle general purpose milling and/or reaming.

That said, up-and-coming machinists often don’t fully understand how the ER collet assembly works and what matters most. Let’s run through some of the basics. Once these are established, we can graduate to the most important component of this holder.

- When choosing a collet to use with a tool, use the same collet diameter as the tool shank, not larger, because there is only so much spring available for clamping. Similarly, there needs to be space between the first flute or blade and the opening of the collet for strong concentric clamping.

- The groove in the collet is for pairing with a ring in the nut. The ring is supposed to be concentric, so don’t attempt to modify it. That’s how the collet clips in and is used to help with easy extraction.

- The nut should always be on the collet before being installed in the holder’s pocket and tightened.

- The cutting tool shank should extend beyond the ground clamping surface and never beyond the full depth of the collet.

As for the tooling components themselves, the collet’s collar-like gripping is usually accomplished by manufacturing from an elastic material such as spring steel. This allows for more points of contact on the tool compared to other chucks.

These points of contact can also add versatility, because the number of segmentations on a collet can vary. More segments mean greater flexibility and a larger gripping range, but at the cost of concentricity and stability on more rigid collets. This kind of natural variability makes collets useful in repetitive work where clamping requirements don’t vary significantly.

These characteristics make collets consumable. Worn collets will cause runout and cutting tools to fail prematurely. If there is any damage to the outside diameter (OD) or inside diameter (ID) of the collet, or marks in the ID where cutting tools may have spun in the collet, replace the collet. Once damaged, collets can’t grip the tool shank effectively, so holding power and accuracy are reduced.

That brings us to the most important — and often overlooked — piece of ER collet systems: the nut. Just how important? If you asked me what makes our holders among the best in the world, I would point to our clamping nuts as perhaps the biggest differentiating factor. We take great care in their design because they introduce and/or manage most of the friction, and friction is the enemy of a collet system.

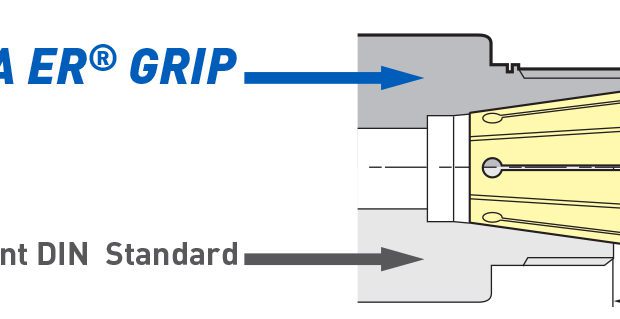

The nut is what pushes the collet down and collapses it. There are two basic designs. Solid nuts are just that: a single piece of steel. There’s a tapered portion that pushes the face of the collet down to compress and collapse it. These slide against the collet face as they are tightened.

The other type of nut is a bearing nut. Small bearings in a raceway surround the nut. As a bearing nut is tightened, the inner seal stays with the face of the collet instead of sliding against it and wearing it. The collet is even free to rotate without the body of the nut, to a point.

You may be thinking, “So the collet face wears more slowly. That’s not enough to convince me to spend more on bearing nuts.”

That’s fair. But you’ve probably heard machinists talk about an endmill slipping and wondered if the right amount of torque was used to tighten the nut.

The bearing nut design can address both issues and others that can arise with ER systems over time. If a nut wears the face of the collet, concentric clamping suffers and can reduce gripping force, which can be hard to recognize before a bigger issue arises.

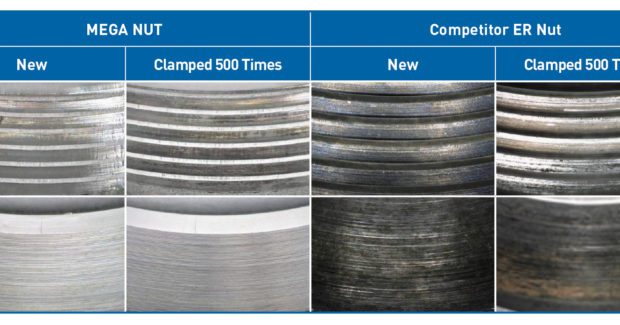

When compared side-by-side to a solid nut after 500 clamping cycles, our MEGA ER bearing nut maintains about 50% more gripping strength with a 30% reduction in runout.

The bearings also reduce required tightening torque by about 40%. Not only is this a relief for operators and machinists, but it also dramatically reduces the chances of slippage or damage from repeated overtightening, which is far more common than it should be. Sure, the threads are going to slide against each other, but reducing required torque can cut wear in half, too.

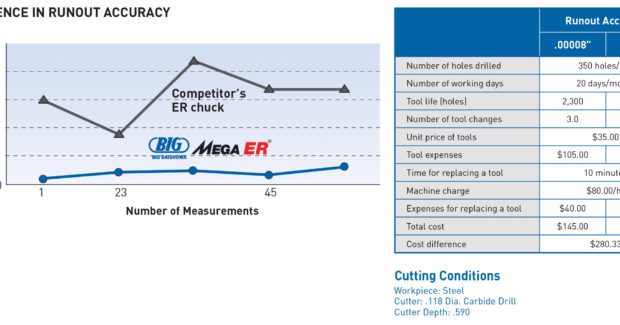

Issues with a collet system are most visibly and impactfully realized in terms of runout. The combination of less tightening torque, concentric clamping and less wear provided by bearing nuts allows them to outperform in this key metric as well. You’re not only preserving the collet, but also another consumable, the cutting tool and the time associated with the change — one of the many long- and short-term efficiencies of bearing nuts.

Nuts are a huge differentiator. They are a big part of the reason we can guarantee all-important runout at the collet nose, with solid nuts, of less than 0.003mm (0.00012 inches) at 4xD on any machine tool spindle in the world.

For the best performance we recommend holders, collets and nuts from the same manufacturer because they’re held to similar standards and tolerances. Our ERN nut, for example, is interchangeable with any other holder brand, but accuracies can’t be guaranteed.

If you’re looking to improve performance on an existing tool, replacing both the collet and nut will provide the most improvement. But if you must choose one, a nut — especially a bearing nut — will make the most impact.