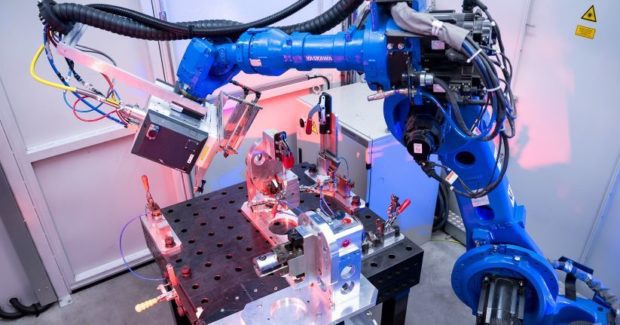

Motoman Optimizes Uptime, Throughput and Quality, On Your Terms

Robots used in arc welding processes have been the best-selling product line for the Motoman Robotics Division of Yaskawa America Inc. (Yaskawa Motoman) The division’s leadership has its eye on rapidly growing categories such as the need for traceability of parts in the automotive industry.

Posted: August 9, 2021

Supplier Profile

By Joe Hazelton and Rachel Duran

The pandemic opened machine shop operators’ eyes to additional areas of their operations that would benefit from automated processes. Think material handling, inspection and traceability. Tier I suppliers to the automotive industry are following the lead of the aerospace industry when it comes to traceability. Yaskawa Motoman’s industrial robots are prepared to meet the demands.

First known as Motoman Inc., the company started in 1989 as a joint venture between Yaskawa Electric America (Chicago, IL) and welding company Hobart Brothers (Troy, OH). Today, the company is known as Yaskawa Motoman.

The joint venture facilitated the direct presence of robotics in the Americas for parent company Yaskawa Electric Corp. (Kitakyushu, Japan). “They expanded their world of automation, “ said Josh Leath, a senior product manager at Yaskawa Motoman’s headquarters in Miamisburg, OH. Leath’s primary responsibilities involve robots and welding.

With a strong focus on mechatronic solutions and nearly 15,000 employees worldwide, Yaskawa Electric has installed more than 500,000 Motoman® industrial robots, 18 million servos, and 27 million inverter drives globally.

Eventually, Hobart Brothers sold its interest in the joint venture to Yaskawa, making Yaskawa Motoman a wholly owned subsidiary of Yaskawa. Currently, Yaskawa Motoman employs about 650 people in the Americas.

In addition to high-performing robotics and products, Yaskawa Motoman’s customers appreciate the division’s dedication to solving their needs and coming up with solutions for their projects after the sale. The division sends out annual surveys to customers to learn where they need to make improvements, and then the division implements those improvements.

According to Leath, when he talks to customers, he asks them why they selected Motoman® robots and why they continue to work with Yaskawa Motoman. “Far and away, it’s because of our very involved level of service, from the quoting process all the way through technical support,” he said.

Robotics Revolution

Robots used in arc welding processes are Yaskawa Motoman’s bestselling product line; however, additional categories have been expanding. “You can’t be reliant on one industry and one application alone,” Leath said. “Over time, and especially recently — even in my four years here — we’ve grown a lot in some of the other type categories. Parcel sortation has grown, obviously with the Covid explosion, of anything to do with warehouse and e-commerce.” Growth is happening with the company’s material handling, paint and coating, and press-tending products, logistics, inspection technology, construction robots, and R&D applications for testing or analyzing a surface or structure.

Leath noted that the advancements in robotics were a major reason for his interest in joining Yaskawa Motoman as a product manager for welding. He stated that the expansion taking place in robotics is different from many industries because the pandemic uncovered and/or brought to leaderships’ attention the fact that their machine shops and processes weren’t as fully automated as they thought they were. For example, take material handling functions.

Here, Leath compared industries to pies. If an industry is mature, then its pie is steady in size — and so are its slices. Each company serving an industry has a certain share of the industry’s market, a certain slice of the industry’s pie. Now, each slice isn’t likely to be the same size as the other slices, but it is likely to be steady in its size. Consequently, Leath noted, the companies serving an industry are “always just fighting for a larger share of that pie.”

However, the pie is different in a growing industry such as robotics. “That pie continues to grow and grow and grow,” Leath said. Moreover, an industry’s growth may be accelerated by outside forces or unexpected forces such as the Covid-19 pandemic. When the pandemic was raging and the world basically shut down in 2020, many companies had to shut down in order to slow the spread of the disease, including factories that had previously thought of themselves as fully automated. Companies quickly realized that their automation didn’t extend to retrieving materials and tools from inventory or to delivering them to manufacturing machines for processing.

“That pie is growing substantially now,” Leath said.

Where Is the Growth? Electronic Vehicles, Inspection and Traceability

Leath said Yaskawa Motoman and its products will have a significant impact on two industries, now and in the future: automotive and inspection. Yaskawa Motoman has customers, Tier I suppliers, in the automotive industry. The industry is changing significantly due to the expansion of the electric vehicle market, as an example.

“You no longer have an exhaust system that you have to weld or put into place,” Leath said, “but you do have a lot of new composites being used.” Those composites require coatings and adhesives that are different from what Yaskawa Motoman typically supplies. Also, besides new materials, there are new parts, too. For example, electric vehicles have battery trays. “Generally, those battery trays are not arc welded,” Leath says. “They might be friction stirred, or they might be laser welded.”

What’s more, the process for joining an assembly of parts may be unknown. In that case, an automotive customer may have to contact Yaskawa Motoman to figure out the right process for a part. Leath said they inquire: “‘I need something else to join this. I can’t use an arc-welding robot. What else do you have?’”

“That’s where we’re seeing a lot of growth,” Leath said, “and where I think we’re going to make the most impact in the industry.”

Leath also saw Yaskawa Motoman heavily involved in the evolving inspection industry. Coincidently, he cited the automotive industry again. Specifically, he cited the industry’s recent emphasis on traceability.

And the reason for the emphasis? Leath pointed to the recall of Takata airbags years ago as an example. In 2016, the recall involved more than 63 million airbags, according to Consumer Reports magazine. The size of the recall is explained in a blog from VDC Research (Natick, MA), a firm that collects information and consults about the technology market. Posted in 2016, the blog summarizes the Takata recall. That year, the recall of Takata airbags was already the largest recall in U.S. history. VDC wrote: “What began as a small-scale recall has continued to expand because of inadequately kept records to trace products to affected vehicles.” And with Takata supplying to the overall automotive industry, the list of automakers with possibly affected vehicles included Chrysler, Ferrari, Honda, Mazda, Mitsubishi, Nissan, Subaru and Toyota.

VDC contrasted the Takata recall with a General Motors recall in 2013, which involved 2012 Chevrolet Volts. The problem was a defect in the brakes that could cause them to lock. The difference was that GM could trace the affected vehicles with barcodes and RFID tags. Consequently, within a month of identifying the defect, GM had used its codes and tags to narrow down its recall from possibly affected vehicles to just affected vehicles. And the number of affected, recalled autos? Four. GM avoided a large-blanket recall of its 2012 Chevrolet Volts, saving money and saving itself from possible damage to its brand. VDC wrote: “Such examples show the importance and benefits of having track-and-trace systems in the auto industry.”

“Takata, of course, realized a worse-case scenario,” Leath said. “They weren’t able to provide traceability and any type of certification on those parts.”

Even though the Takata brand disappeared, its effect on the auto industry didn’t. “All Tier I automotive and sub-tiers are being told by OEMs: ‘We need traceability. So, if you’re telling me this exhaust system or this seatback system is made out of this metal, I need proof. If you’re telling me it meets this weld spec, I need proof.’”

Yaskawa Motoman has the means for providing proof: its robots. Data can be collected internally via the robot controller or can be collected externally via a local server or a programmable logic controller (PLC). So, when it comes to collecting data as part of an inspection process, as Leath said: “We can do that very easily with robots. We have external tools that we can utilize that collect data from the robot, which is needed as part of that report.”

Traceability is more common in the aerospace industry than in the automotive industry. How common is it becoming in the automotive industry? “It hasn’t been until it has to be,” Leath noted.

Founded in 1989, the Motoman Robotics Division of Yaskawa America Inc. is a leading robotics company in the Americas. With more than 500,000 Motoman® robots installed globally, Yaskawa provides automation products and solutions for virtually every industry and robotic application, which includes: arc welding, assembly, coating, dispensing, material handling, material cutting, material removal, packaging, palletizing, spot welding and clinical laboratory specimen processing.

Yaskawa Motoman Re-Accredited by IACET for its Educational Programs

Yaskawa Motoman’s training programs were recently accredited for five more years by the International Accreditors for Continuing Education and Training (IACET). “Yaskawa Motoman is proud of our educational programs which train hundreds of engineers and manufacturing personnel each year in important robotics skills,” said David Troeter, vice president of support services for Yaskawa Motoman. “Our renewed partnership with IACET is a demonstration of our commitment to lifelong learning and high standards for all of our programs, and we are very pleased to be recognized by such a prestigious organization.”

Yaskawa Academy offers:

- Robots in classrooms for hands-on learning

- Application-specific classrooms

- A large, well-equipped welding lab for hands-on learning

- A comprehensive training curriculum with more than 75 different courses, including basic programming, advanced programming, maintenance, concurrent I/O, purchasable options and customized training.

The IACET awarded to Yaskawa Motoman the status of accredited provider, which means the company can offer IACET CEUs, and which covers all programs offered or created during that time. IACET is approved by the American National Standards Institute for continuing education and training.

Fast Facts: Yaskawa Motoman

- Founded in 1989, Yaskawa Motoman is a leading industrial robotics company in the Americas.

- Yaskawa Motoman’s headquarters in Miamisburg, OH, is home to several functions, including:

- the Standards Group – responsible for standard solutions, including versatile robot models, intuitive software, advanced sensors, and fully integrated “world” solutions.

- the Automation Group – responsible for complex, challenging, or unique applications that require a fully integrated automation solution. This team designs and executes innovative solutions that are tailored to a customer’s exact requirements.

- Yaskawa Support Services – nurtures long-term customer relationships through a wide range of solutions to ensure long-term performance. Support Services includes technical support, field service, parts inventory, repair/retrofit and life cycle management. Also, there’s a comprehensive training curriculum available through Yaskawa Academy, for hands-on learning and IACET accreditation.

- Yaskawa Motoman is backed by a powerful parent, Yaskawa Electric Corp. of Japan, which is one of the world’s largest manufacturers of industrial robots. The company has installed more than 500,000 Motoman® industrial robots, 18 million servos, and 27 million inverter drives globally.

- Yaskawa Motoman offers a wide variety of industrial robots, including collaborative, delta, and SCARA models. It also offers a line of pre-engineered “world” solutions that are complete, application-specific robotic systems that include robot, process and safety equipment.

- Sister division Yaskawa America Inc., Drives & Motion Division, manufactures various control products, AC servo motors and drives and inverters.

Source: www.motoman.com