The Components of Maintaining a Strong Saw Operation

Maintenance, training and implementing best practices are crucial to improving your saw operation.

Posted: October 29, 2021

WEB EXCLUSIVE

By Russell Enzenbacher

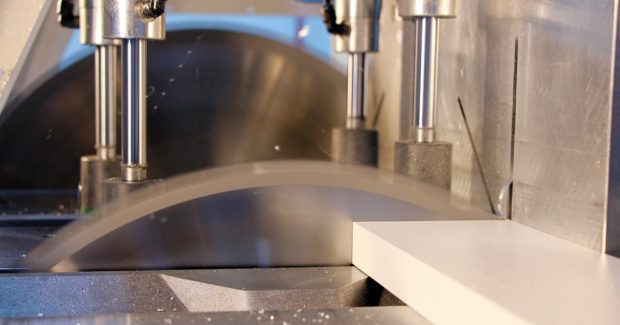

In the fabrication world, saw operations are critical. Whether using a compound miter saw, a radial arm saw or a table saw, it is imperative for a fabrication shop to ensure its equipment is in pristine condition for both quality and safety purposes. If a saw is not functioning properly, there is not only a greater risk of injury, but malfunctioning saws can also produce undesired results, such as material not being cut to proper length or out of square. By following a proper maintenance schedule, training protocol and best practices, costly mistakes can be avoided.

MAINTAIN THE MACHINE

Keeping a saw clean is critical for proper saw maintenance. Over time, resins build up on the cutting edges of saw blades, coating the edges and making the blade act as though it is dull. Dull saws lead to an increase in friction and heat, making cutting more difficult and resulting in uneven edges. While it may seem counterintuitive, dull blades are more dangerous than sharp blades because of the additional force required to make the cut.

It is equally important to properly lubricate the saw’s moving components per the manufacturer’s specifications. After each use, the saw and blades should be cleaned and lubricated per the manufacturer’s guidelines. Both wax and lubricant will assist in keeping rust off a saw blade.

THE PROPER TRAINING

When staff members are properly trained, the saw will operate more safely and efficiently, producing stronger results. For larger and more complex saws, the manufacturer will usually offer training with the saw purchase, along with additional training to new employees at a cost. Trade schools will also provide a great foundation for basic saw operations.

However, most training will be on the job with a senior fabricator who has experience on the saw. Learning from industry veterans can help prevent injuries to employees less familiar the machine. This can also improve efficiency, which will only help the bottom line of the company. Learning from established co-workers will encourage the staff to utilize best practices learned over the years.

BEST PRACTICES

While using a saw, workers should make an effort to protect their eyes, face, hands and forearms by using personal protective equipment (PPE). Leather aprons, safety glasses with side shields or full-face shields are also highly recommended forms of safety gear. Furthermore, operators should try to avoid wearing loose-fitting clothing and gloves as they may be caught during the cutting process.

It is always important to verify the saw blade being used is suitable for the type of material being cut, as well as the type of cut being made. Thinner blades with more teeth are better suited for making scroll cuts, tight turns and best used with thinner material. Wider blades with less teeth, alternatively, are good for making rough cuts on thicker material. In either case, the saw blade needs to be set to the proper tension before using it. One should also ensure there are no bent sections, broken teeth or additional damage on the blade.

It is highly recommended to develop and follow a cut list. This will ensure the saw operator is getting the most out of the materials on hand and can cut everything on the list. When used correctly, a cut list can be helpful in layout, confirming key dimensions and estimating material needs. It can also indicate the order of construction and serve as a record of the build in the rare case a project needs to be replicated again.

Establishing and following recommended maintenance, best practices and training protocols will have a profoundly positive effect on a fabricator’s saw operation. It will allow for the fabricator to process material more efficiently, leading to time and money savings. Not only will following the right steps improve efficiency and output during saw operations — not to mention extend the life of the machine and blades — but it will also protect the health and safety of those operating the machine.