The Right Toolholder Can Help Your Process Exceed Expectations

Toolholding considerations are often one of the last thoughts during a setup process, but the toolholder determines the success of how the cutting tool performs. When was the last time your shop reviewed your toolholders?

Posted: November 26, 2021

DEPTH OF CUT

By Jeff Wills

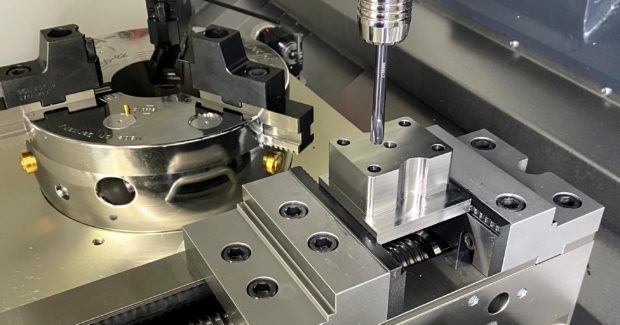

Optimizing a manufacturing process for output while minimizing waste requires careful selection of every component. Determining the right machine tool, workholding and cutting tools all help, but there are some commonly overlooked items. This includes the toolholder, which is critical in delivering torque to the cutting tool while also making sure it runs true to the spindle. Different types of toolholding can make achieving and maintaining certain features in a process possible. Whether that is reducing the use of consumables, decreasing cycle time, tool changing considerations (flexibility versus ease of use), workpiece or fixture geometry constraints or maintaining accuracy over a longer period, different methods of toolholding will net different results. This requires process engineers and manufacturing personnel to carefully consider the benefits and potential tradeoffs of the different technologies on the market.

A high-volume transfer line environment is going to benefit from different features than say a five-axis machine that is used for prototype work, especially when it comes to toolholding. For example, the transfer line environment is going to be more interested in reducing consumables (cutting tools) and decreasing cycle time. Less interested in flexibility during tool changes, because there will more than likely be established tooling assemblies used. So how to go about choosing the right toolholder for the job? If tool selection is critical, something like a tool selection matrix could be used to help make the right choice. For the purpose of this article we will cover the basics as to what toolholder types lead to certain results.

If maximizing tool life and minimizing consumable cost is important, then the use of a precision type toolholder is key. A precision type toolholder will ensure that the cutting tool is running as close to spindle condition as possible. With a good spindle, drawbar and pull stud that typically leads to less run-out. Run-out being the single biggest contributor to tool life. There are several rules of thumb as to how run-out negatively impacts tool life, the most common one is, “every tenth of run-out results in a 10% loss of tool life.” A precision toolholder is one that will consistently repeat to a run-out value of 0.003 mm or less over the life of the holder. What is important to look for here is a one-piece holder like a hydraulic toolholder or heat shrink style. The one-piece design is critical in ensuring that multiple components do not clock and wear relative to one another, ultimately resulting in inconsistent results between tool setups.

Next to consumables is saving machine time or reducing cycle time. Changing the toolholder while leaving all other variables constant has shown to effect cycle time. This is trickier than reducing run-out because the various manufacturing processes react differently to different holders. For example, using a standard side lock/Weldon holder is excellent for heavy milling applications. They positively lock the tool in and allow for very aggressive material removal rates (MRR). However, a process like drilling or reaming, on the other hand, will benefit from a precision toolholder, like mentioned previously. Allowing the drill to cut evenly between the flutes will result in faster feed rates. There is also the possibility to save machine time or shop time by reducing secondary operations. If a part calls for a certain surface finish, changing toolholders may be able to increase the surface quality of the part, potentially reducing labor intensive operations like polishing. Holders with damping capabilities, like hydraulic holders, or certain milling chucks could be of use here. Next to increasing tool life, reducing cycle time has the biggest potential for a return on investment for a specific toolholder. This can be done by understanding the most critical elements of a given machine cycle (part finish/tolerance, specific machining process, etc.), making some educated guesses as to which holders will most likely succeed and then testing.

WHICH TOOL SETUP IS RIGHT FOR YOUR SHOP?

With the large variety of shops operating in the marketplace today, it is understandable that there are differing requirements when it comes to tool setup. Some shops require holders that can clamp a variety of tool sizes with minimal change over. Others require error proof setups when one tool size will only fit into a specific holder. When it comes to flexibility the various styles of collet chucks available are hard to beat. One holder can use a variety of collets to clamp on a large range of tools. Not just nominal sizes, but high speed steel (HSS) tools as well, which may not have an accurately ground shank for clamping. The range on a single ER collet could be as large as 1 mm, allowing tools everywhere in between to be clamped. If even more flexibility is required when it comes to drilling, drill chucks (as the name implies) work on clamping a range of drills over a 15 mm diametral range or more.

Other holder types, like milling chucks and hydraulic toolholders can sometimes use reduced bushings or sleeves to adapt to different size tool shanks. However, here a higher quality tool shank is still required for proper clamping. Some shops want to avoid flexibility to reduce the chance of error during tooling setup. Putting non-sealed collets or sleeves with a coolant fed tool, in a thru spindle coolant application could lead to very decayed tool life. Relying on direct clamping in shops like this can help minimize any setup errors. If a holder can only clamp on one size tool it will prevent the wrong collet, sleeve, or tool from inadvertently being installed. Heat shrink holders must be used in a direct clamp situation. Hydraulic holders, like SCHUNK’s recently redesigned Platinum V2 line come in a variety of sizes and lengths to fit any direct clamping needs. The added benefit being the ease of use with a hydraulic holder, and no auxiliary equipment required for tool changes.

The last big consideration for most shops regarding toolholding comes from clearance and accessibility around the workpiece, machine or workholding/fixturing. In this case, usually longer and slimmer is better, but as with most things, there is a tradeoff. Longer and slimmer holders are less rigid and more prone to deflection. For this balancing act there are a variety of options, including various types of extensions, which use all the tool clamping methods described thus far, from collet extensions to hydraulic extensions or less common methods. For example, SCHUNK’s TRIBOS Polygonal Clamping, which next to a necked down, extended length cutting tools is the slimmest option available. Extended gage length holders are also available which help keep the setup as rigid as possible by offering a one-piece solution from the spindle down to cutting tool. On the other hand, some accessibility issues arise from a lack of Z axis height on a machine. Here a variety of “zero” gage length holders are offered to maximize this accessibility. Whatever the exact situation is, there are a variety of toolholder shapes and sizes on the market to help reach the workpiece. Most manufacturers also offer the option to produce custom length and size toolholders to fit a specific process. While sometimes this may seem like an expensive option upfront, investing in the process with the proper holders will often pay for itself many times over along the life of the holder.

While toolholding sometimes falls victim to being one of the last considerations during process setup, there is high potential upside for taking process considerations into account during this selection. Being the closest component to the cutting tool, the toolholder ultimately determines the success of how the cutting tool performs. Whether the cutting tool’s life is cut short due to uneven chip load, it runs slower than it otherwise could, or if it can even make contact with the workpiece, are all determined by the use of the proper toolholder.

Living and working in the manufacturing industry requires us all to continually examine what we do daily and look for potential improvements. When was the last time you looked at your toolholders?