Tool Management Systems Aren’t Just for Managing Tools Anymore

Today’s tool presetters capture all the data associated with a tool in order to expediate setup in the tool crib, reduce scrap and waste, and even track what’s happening on the shop floor. Presetters act as a communication/data hub, capable of integrating with CAM software.

Posted: November 6, 2021

TOOLING & WORKHOLDING

By Jim Mayer

Cutters and tool holders account for a big part of a machine shop’s business. Just like a link in the chain that is a shop’s workflow, they represent a chance for efficiency or inefficiency. And just like any other capital expense, how you manage and deploy them after the initial investment affects your return.

When you really think about it, the time a tool is in the spindle cutting accounts for a fraction of its impact on the shop; shops know how much of their purchasing budget goes to tooling, but few know how much value is gained or lost throughout the tool’s lifetime.

Whether you realize it or not, the impact of tool management is felt every day. We see it on the shop floor far too often: a machine is scheduled, the stock is on the table and it turns out a holder is missing. Sometimes it’s in the shop somewhere, sometimes it’s not; either way it’s costly when production is delayed or stopped.

Even when the right tool is somewhere in the shop, it’s difficult to quickly gather its wear state and measurements. Tools and holders throughout a shop are generally all at different stages of wear. Mistakenly using a refurbished holder that’s ever-so-slightly out of balance may not be as ideal for finishing work as the new one on a cart a couple of machines over. On the other hand, picking a new tool when there’s a perfectly good used or refurbished tool available for the job drives up costs over time.

PRODUCTION COSTS

Storage also becomes an issue when tools aren’t managed properly. Tools are expensive and, in many cases, delicate. In drawers or shelves where tools move freely, cutters can get damaged, and it may not be noticeable until a part doesn’t turn out right. It happens far too often and is totally avoidable.

It’s estimated that 30-60 percent of tools are stored in machines. Unfortunately, time is wasted when machinists have to search for tool changers and take tools in and out, looking for what they need for another job. Not to mention, most 15-minute setups done in the spindle take a minute or so offline with a presetter—more on those just a little later.

The costs of poor tooling management go beyond the mad dash to find a holder, placing already-worn-out cutters in the bin or mismeasuring an offset with a ruler. Acquisition, inventory management, assembly, wear and dispensing of tooling components all happen with a certain efficiency — or inefficiency.

INVENTORY COSTS

Just like any other inventory, tooling is essentially cash on the shelf. A lack of visibility and/or traceability lead to some fundamental errors of inventory management. For one, unused tools equate to unused capital. According to research, typically about 80 percent of the tooling components in regular stock are used just twice a year — the definition of excess inventory.

Redundancies are another no-no of inventory control. Regardless of the root miscommunication that led to it, unintentionally having multiples of the same tool, sometimes from different suppliers, is wasted spend that could have been used otherwise. Plus, a lack of visibility to their histories makes choosing between which to use a challenge.

There’s also often a gap in the tracking of durable and consumable tools. Without an understanding of what’s been used and how much productive life is likely left, it’s nearly impossible to understand the value of what’s in the tool room. And the same goes for obsolescence, there are a lot of tools on shelves out there that aren’t right for the work anymore.

COMMUNICATION COSTS

Some shops may have separate engineering, manufacturing and procurement departments—among others. They all look at tools from different perspectives: Engineers think in terms of drawings; procurement thinks in terms of bill of materials, and machinists think in terms of offsets and diameters. Each document transfer, meeting or phone call making sure everyone is on the same page, can cost valuable time and increase the chances of error.

The simple difference between “mini” and “micro” could result in a wrong order being placed or the wrong tool being assembled. Especially true of growing shops, the moment a new shift starts, a whole new hunt for where tools were left begins.

Should it escalate to a sudden need for a tool, knowing what suppliers and distributors can deliver and when is key. Without a history of where tools came from, when and how quickly they can be delivered, precious time is wasted calling around looking for what’s needed.

PLANNING COSTS

Last but not least, without knowing exactly what’s in the shop makes it difficult to look ahead. Shops only grow if they invest in themselves. Smart investment requires planning. Without clear and somewhat predictable visibility to tooling costs, productive investment can be delayed. Unnecessary tooling on the shelves, or ordering tools that are already on hand but can’t be found, is money spent that could have been invested in people or capital equipment.

Similarly, without visibility to tool stock, status—in terms of new, worn or refurbished—or restocking schedules, it can be difficult to confidently estimate the cost of a job. And in instances where the right tool wasn’t ordered, sudden orders incur rush charges that weren’t budgeted.

Sometimes these situations happen. The question is are you ready and how quickly you can adjust? The old way of doing things is reactive, while today’s tool management systems put you out in front of things.

APPROACHABLE INDUSTRY 4.0 SOLUTIONS

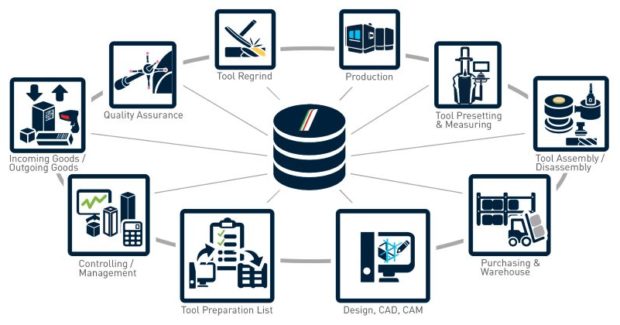

Modern tool management systems have rallied around the inter-connectivity idea of Industry 4.0. From product design to modeling, to materials management to quality control, tool management systems can organize all the information about the product manufacturing lifecycle in a single place.

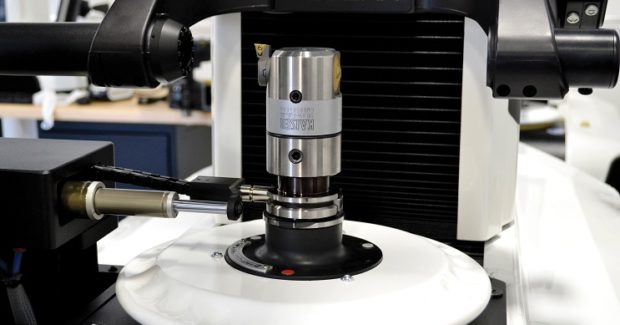

That brings us back to presetters. They’ve evolved beyond equipment that’s simply used to reduce setup time and tooling costs by eliminating error and adding precision. Think about all the data associated with a tool: dimensions, usage, age, assembly runout, etc. Today’s presetters capture all of that — and then some — so you can leverage it to expedite setup in the tool crib, reduce scrap and waste, even track what’s happening on the floor.

Presetters now act as a communication/data hub too, capable of integrating with the engineer’s CAM software. This bridges the gap, all but eliminating manual time needed to verify length, diameter, create a G-Code and post process with exact tooling values, and avoid costly miscommunications between programmers and assembly.

Another approach is using a presetter to embed a tool’s assembly data and history using RFID chips. It’s probably the most accurate means of transferring tool data between machines, allowing you to track the life, or expected obsolescence of a cutting edge, holder or assembly.

Not only does this allow you to plan and manage inventory, but you can revisit how tools wear on certain jobs and adjust. Or, if the same machines are producing different results on the same job, you can identify the exact tools used, find out what’s causing the discrepancy, and diagnose machine or spindle issues before they get worse.

Combining a scalable software structure with local workstations is the most advanced solution out there now. A tool management system, like our Intelligo, links the entire tool library, active or inactive, with CAM, tool-crib management, purchasing, scheduling and ERP software. Intelligo focuses on where everything is happening: the shop floor. Using RFID or QR codes, Intelligo recognizes everything from cutters and holders, storage cabinets and carts as they travel the shop.

You read that right. Our Speroni UBI station is just one example of how software integration and connectivity can help track just about anything you need. Real-time visibility to stock makes it easier to allocate resources. You can even control access to certain areas of the station. In addition to convenience, tracking when tools come in and out and for how long, you can easily organize your shop to have tools where you need them when you need them.

This level of traceability and real-time access to data reaches throughout a metalworking business and makes it more agile. Planning is made simpler, cash flow is controlled, communications are streamlined and operators have what they need when they need it.

Jim Mayer is the manager of TMS for Big Kaiser Precision Tooling. Email jim.mayer@us.bigkaiser.com.