Data-Driven Welding: Ensuring Productivity, Quality and Success in an Industry 4.0 World

Digital data support allows your shop to pinpoint slowdowns in the production process because you can visualize the entire welding operation, down to individual weld parameters, for example.

Posted: December 18, 2021

WELDING

By Gary Abke

The traditional manually driven world of fabricating and metalworking has become increasingly digital, particularly over the past decade. Much of this evolution away from the analog world stems from the increasing adoption of an Industry 4.0 mindset.

WELDING, DATA AND INDUSTRY 4.0

Welders have always relied on data to track productivity and quality, traditionally through manual collection methods. The amount of data can be overwhelming, and the efforts to collect it, time-consuming. There is often too much data out there for any one organization to manually sift through, analyze, and put into action.

When Lincoln Electric introduced the first generation of its CheckPoint® Production Monitoring at no cost on Power Wave® machines more than two decades ago, no one knew how powerfully the digital world would influence all aspects of life, including manufacturing.

These early weld production monitoring systems collected only the most basic weld data that would be reviewed in spreadsheet format. Users could only view this information from a single, dedicated workstation on the shop floor because there was no such thing as the cloud back then. At least not for fab shops. Because this data was so vast and raw, it was hard to transform it all into something useful. Users found themselves picking and choosing what they needed from the system’s data dump.

As we all know, technology evolves at lightspeed (or perhaps even faster). Weld data monitoring programs, like CheckPoint, moved to higher levels of functionality over time. Now with IIoT and Industry 4.0, it’s possible to truly connect power sources with weld data monitoring on manual or robotic lines for easy viewing, retrieval and analysis of real-time data from anywhere on any mobile device via the cloud.

DIVING INTO DATA-DRIVEN WELDING

When fab shops add the power of weld data monitoring to the floor through power sources equipped with this technology, the way they work changes. Welders, welding engineers, managers and more can uncover what drives welding performance and quality.

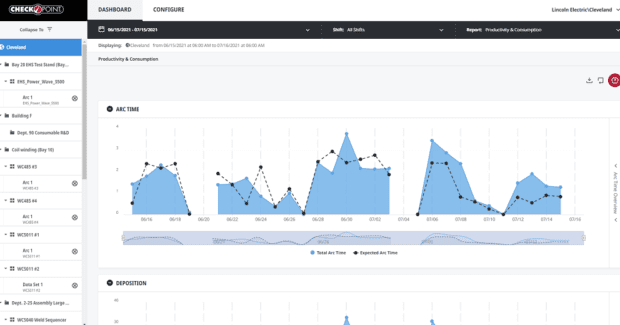

Real-time, visual access to point-of-weld data eliminates manual data analysis using spreadsheets. Users instead surface their essential weld data on interactive dashboards, charts and graphs built with the user experience in mind. It all comes down to data simplicity.

Let’s say a shop consistently faced production slowdowns, and while management thought it was the welding line based on rough manual data, they couldn’t precisely pinpoint where throughput issues occurred. Without digital data support, they would need to do some heavy sleuthing to pinpoint the exact location and cause, always a challenge with spreadsheets.

Modern weld data monitoring systems allow users to visualize the entire welding operation from a bird’s eye view of efficiency down to more granular levels, including individual weld parameters. Talk about smart manufacturing and actionable information that can improve throughput and eliminate bottlenecks on the shop floor.

KEEPING AN EYE ON PRODUCTIVITY

Today’s digital, data-driven welding environments not only track and collect vital information about the welding process at each station but also automatically calculate and transform the data into industry-specific key performance indicators (KPIs).

Using weld data monitoring and these KPIs, operations can easily identify from any mobile device or computer what welding stations are running, what operators are welding, and what weld parameters are being used. The real-time, at-the-weld data they capture gives them full visibility to important metrics, such as arc-on time, wire deposition rates, operating factor, and overall equipment effectiveness (OEE).

Such factors can make or break a productive welding line. By delivering real-time insight into them, modern weld data monitoring tools allow organizations to quickly visualize and resolve bottlenecks and get back up to full-speed production rather than poring over spreadsheets to detect the problem’s source.

Consider this example. A fabricator wants to align production goals with arc-on time. If they used a weld data monitoring system, such as CheckPoint Production Monitoring, they would be able to easily calculate and capture instantaneous arc-on time for the entire production line. They also could distill this information down to individual welders. Managers can use this valuable information to analyze throughput trends and other issues that drive or hinder shop floor productivity. By zeroing in on all of the factors surrounding a particular KPI, such as arc-on time, organizations can effectively use data to adjust personnel and processes in their welding lines.

QUALITY CHECKS AND BALANCES

For most fab shops, productivity tends to drive weld data monitoring adoption. Quality assurance, however, is another important part of the conversation. As manufacturing quality standards and certifications grow more stringent, more shops need to ensure their operations have verification, tracking, and backup data to support all QA claims. Weld data monitoring simplifies this process by gathering all of this valuable data at the source and providing a virtual paper trail of individual welds to identify the root of quality issues.

Even just one out-of-spec welding parameter can yield defective product, rework or even a stoppage. All of this can put a huge dent in a fabricator’s bottom line. Checks and balances are essential. Weld data monitoring arms fabricators with the information they need to keep tabs on the quality process and results.

It goes beyond that, however. Weld data monitoring platforms may also help stop failures before they happen. Proactive, KPI-based monitoring allows operators to establish and monitor weld parameter limits to identify problems in real time, using alerts that flag deviations from the spec. This can eliminate revisiting data surrounding the suspected weld process that resulted in a quality failure through data archives.

ARE FABRICATORS READY TO CONNECT?

For fabricators that have not leaped into the digital, data-driven world of manufacturing, the welding line is a great place to start. It’s not difficult to launch cloud-based weld data monitoring on the shop floor.

They should first consult with their IT department to ensure the proper networking infrastructure is in place or have it installed if it is not. They’ll also want to be sure they have the right power source to make weld data monitoring a possibility. Success in today’s increasingly “smart” manufacturing world relies on making the most of IIoT. It’s now easier than ever to harness the powerful data that makes all of this happen.

Gary Abke is the director of advanced technology products for The Lincoln Electric Co. Email gary_abke@lincolnelectric.com.