Best Practices in Safety

Industry professionals share insights and products to assist in fostering zero injuries in your shop.

Posted: January 28, 2022

Start the year off right by evaluating products thoughtfully and practically designed to prevent injuries and keep your team safe, including tips on the safe handling and preservation of battery life in power tools.

Gloves Offer A4 Cut Protection, the Most Breathable in Its Class

Brass Knuckle® Safety Products (Alpharetta, GA) offers the SmartCut™ BKCR4420, which offers A4 cut resistance with double-coated protection that combines slip resistance and permeation protection in a dexterous glove.

A foam nitrile top coat adds grip security for oils, petrochemicals, fuels and most acids. The sandy grip finish increases abrasion resistance and cut protection, all while being the most breathable and flexible glove in its class.

Over a high-density polyethylene shell goes a greener-formula water-based polyurethane coating as a palm and finger base coat that helps reduce penetration of liquids, including light oil. In this method, the polyurethane is infused into the glove with water rather than with potentially harmful chemicals such as dimethylformamide. The result is a superior, long-wearing glove that feels softer and provides excellent breathability, fit and manual dexterity, without the bulk. It also reduces cumulative exposure to chemicals.

The gloves are excellent for use in metal work, automotive, and stamping or for work in the oil and gas industries. It stands up to construction, glass handling, general industry, and HVAC while being dexterous enough for assembly work, small parts handling and shipping. www.brassknuckleprotection.com.

Tips for Longer, Safer Power Tool Battery Life

The Power Tool Institute Inc. (Cleveland, OH) has compiled a list of best practices for safer use of batteries and power tools. Power

tools and their batteries are rugged instruments designed to perform tough jobs, but they still require care to maintain safe, optimum performance. There are steps users can take to extend tool and battery life and help keep power tools operating at peak performance.

- Safe handling: Start by reading the manufacturer’s instruction manual – and only use original manufacturer’s system components of tool, battery and charger. Do not impact or damage a battery (for example, do not use it as a hammer), use it solely for the defined purpose as specified by the manufacturer. If a battery has received a sharp blow, been dropped, or is damaged, discontinue use.

Regularly inspect batteries for signs of damage, such as crushing, cuts or punctures. Be mindful of abnormal battery behavior, such as failure to fully charge or hold a charge, longer-than-usual charging times, noticeable drop in performance, liquid leakage from the battery, or melted plastic anywhere on the pack. These are indications of an internal problem. Never modify, disassemble, or tamper with the battery because the performance can become unpredictable and dangerous. As a general practice, it is best to unplug battery chargers and remove battery packs from them when not in use.

- Safe storage: Do not store batteries on their chargers. Always use and store the battery within the temperature limits stated by the manufacturer. Do not store in a closed location where sunlight may cause elevated temperatures, such as near a window or inside a vehicle. Do not store or transport the battery in a container with loose metal objects, such as coins, keys or nails, which may contact the terminals.

- Safe response to overheating: Though batteries and chargers are safe to use when operated properly, in rare instances a battery may overheat. If the battery is exhibiting signs of overheating (flames, smoke, smoldering or melting), immediate action is required. If connected to a charger when exhibiting signs of overheating, always unplug the charger first. After unplugging the battery charger, then pour copious amounts of water on the battery and then submerge the battery (including any attached tool or charger — do not directly touch/disconnect the battery) in a sturdy container filled with water. When transferring the battery, avoid direct contact with the battery (use a long-handled shovel) and use appropriate personal protective equipment to protect face, hands and body because there is a risk that overheated batteries may vent, explode or emit flame.

If the battery is exhibiting flames, continue using copious amounts of water until the flame is extinguished, then submerge the battery (including any attached tool or charger) in a sturdy container filled with water. If water is not available, dirt, sand or a conventional ABC extinguisher may be used in an attempt to smother and cool the battery until water is available. Keep the battery submerged, in a well-ventilated location, for at least 24 hours and at least 15 feet away from any combustible items. Contact the manufacturer for guidance on proper disposal. www.powertoolinstitute.com

Milwaukee® Adds Safety Helmets to PPE Lineup

Milwaukee Tool (Milwaukee, WI) has added to its Personal Protective Equipment (PPE) lineup with the highly anticipated introduction of Milwaukee® Safety Helmets. The helmets are available in front brim and no brim styles, and in vented (Class C) and unvented (Class E) options. The new helmets provide better protection and more comfort than other options currently available.

“With more than half of fatal work-related traumatic injuries resulting in falls, workers are becoming more aware of the dangers of slips, trips, and falls,” said Zach Richman, group product manager for Milwaukee Tool. “For that reason, there is a growing trend in helmet adoption by general contractors and subcontractors because helmets offer side protection whereas traditional hard hats only include the top of head protection. Unfortunately, some helmets on the market today often sacrifice safety for comfort and style (and vice versa). With our new Safety Helmets, you don’t need to make that trade-off, as they provide a high level of both safety and comfort.”

The helmets are BOLT™ compatible with four accessory slots and two universal accessory slots, allowing users to adapt to their jobsite and easily attach additional PPE and accessories. Additionally, the helmets include a BOLT Headlamp Mount that is suitable for most headlamps and a BOLT Marker clip so users can attach and easily access pens, pencils and markers.

The safety helmets are ANSI type 2 and meet energy absorption capacity clauses 4.2.1.2 (front), 4.2.1.3 (side), and 4.3.1.4 (read), and Retention System clauses 4.3.3 (Strength) and 4.2.4 (Effectiveness) of EN12492:2012. They are offered in seven colors.

www.milwaukeetool.com/ppe

Preventing Back Injuries With Lift Tables: A Brief Case Study

The Company: An industry leader in the manufacturing and supplying of fiberglass booms, with an extensive history focused on producing superior booms to match the design and function of each insulated aerial unit they service. Their dedication and expertise have led to a global reputation for providing dependability in fit, strength and non-conductivity.

The Problem: The filament winding process was an exhaustive and manual process. The process required employees to manually lift and load layers of pipe, weighing more than 100 pounds, from a low-level powered cart into a machine known as the Winder. Due to the weight of the pipes, this manual and strenuous process resulted in numerous employees sustaining back injuries. As a result, finding the right safety solution became a high priority.

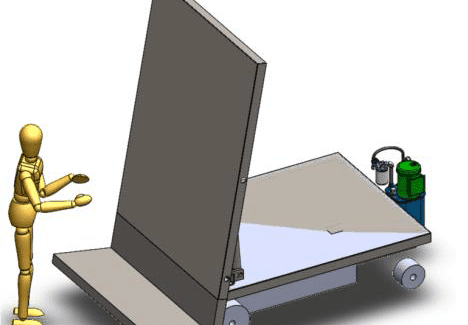

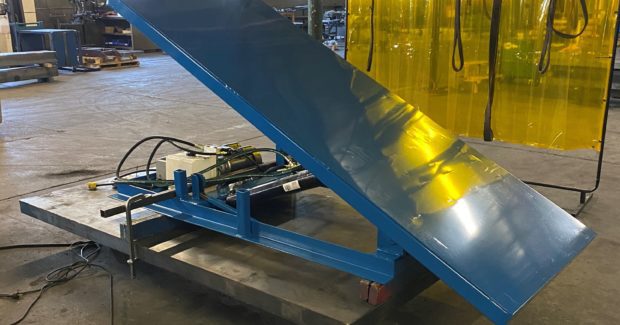

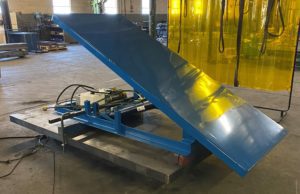

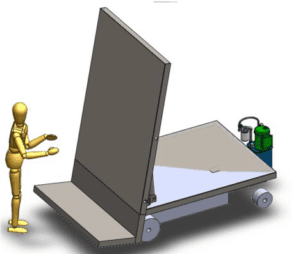

The Solution: The company’s engineering team and the Blue Giant Equipment Corp. (Mississauga, ON Canada) sales engineering team worked together to develop a safety solution. The solution was to customize a Blue Giant tilt table that could raise a layer of pipes from a horizontal position to a vertical position. This allowed the cart to be driven into the Winder, eliminating the need for employees to manually lift and load the pipes. The Blue Giant team developed and customized a Blue Giant Hydraulic Upender (HUE-20-90) and through 3D modeling and file collaboration between engineering teams, helped design a fixture to hold the pipes in place for unloading. This safety solution allowed this once intensive and manual process to become fully automated, resulting in increased productivity and safety for employees.

Features:

- Upenders are ideal for the safe re-positioning of pallet loads and odd shaped objects

- 0° to 90° tilt angle

- Can be customized

- Can be mounted to the lift table platform to assist with positioning

Blue Giant lift tables are designed to improve operator ergonomics and product positioning. They help keep product nearby, eliminating unnecessary reaching and other operator movements, therefore enhancing ergonomics. Blue Giant lift tables can be built in virtually any size and capacity and can be customized to meet specific application requirements. Vertical travel ranges from 24”-to-72” and load lifting capacities of up to 12,000 pounds. — Written by Sharifa Clarke, digital communications specialist for Blue Giant.

www.bluegiant.com/Products/Lift-Products.aspx