Civan Lasers and Smart Move Partner on Solutions for Welding and Additive Manufacturing

Controlling a dynamic beam laser with galvo scanner enables on-the-fly beam shape orientation changes, delivering new welding and laser powder bed fusion capabilities.

Posted: January 26, 2022

Civan Lasers (Jerusalem, Israel) and Smart Move GmbH (Garching, Germany) have partnered to provide customers with new welding and laser powder bed fusion (LPBF) additive manufacturing solutions. By steering Civan’s dynamic beam laser (DBL) with Smart Move’s ultramodern laser scan head, welding and LPBF customers can now change beam shape orientation on the fly, enabling the use of nonsymmetrical beam shapes in complex geometries and making previously impossible applications a reality.

Civan’s patented coherent beam combination modulates beam shape as desired at speeds of up to hundreds of megahertz without any moving parts. This entirely new category of lasers uses optical phased array coherent beam combining to merge many single-mode laser beams into a larger beam. Each laser’s light overlaps with other beams in the far field, creating a diffraction pattern that makes it possible to manipulate the beam shape in real time. Phase modulators control the individual beams, and the resulting interference pattern can be adjusted to maximize the beam spot position and produce various shape patterns inscribed by the beam’s motion.

In addition to beam shape, Civan’s DBLs also enable control of shape frequency, shape sequence, and depth of focus. The ability to control these parameters is a powerful tool for optimization of evaporation in the capillary, the flow in the molten pool, and the solidification of the melt for any laser materials processing application. Such control does away with pore, spatter, and crack formation while increasing feed rates and speeds in welding and additive manufacturing applications.

“Smart Move makes the fastest and most accurate scanning solutions available,” says Civan CEO Dr. Eyal Shekel. “The integration of our dynamic beam laser with state-of-the-art scanner technology allows welding and LPBF customers to not only improve welding feed rates and additive manufacturing speeds, but also make previously impossible applications possible.”

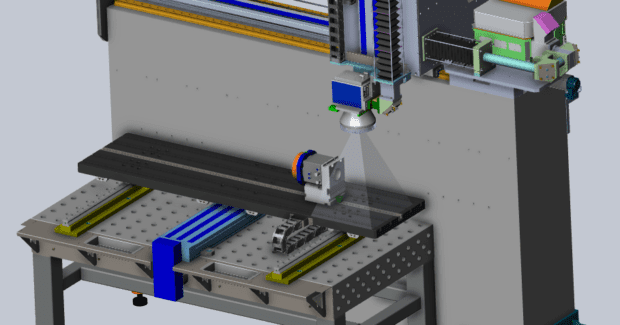

Civan and Smart Move have completed development of a scanner (Figure 1) for LPBF, which was delivered to a large LPBF systems manufacturer. Another scanner has been made for BBW Lasertechnik and will be integrated in a welding system (Figure 2). In addition, Civan and Smart Move are collaborating on a project with Fraunhofer Institute for Laser Technology to develop a process for welding bipolar plates used in fuel cells.

Each fuel cell requires 300–400 bipolar plates, just hundreds of microns thick, with a weld seam of 3–6 m. The demand for bipolar plates is high, but previous efforts by other companies to increase bipolar plate welding speed to more than 0.5 m/sec have resulted in welding defects. However, Civan, Smart Move, and Fraunhofer ILT are now driving this program, dubbed the Eureka Project. The three organizations aim to use a galvo scanner and advanced real-time process monitoring to control beam wobble at megahertz frequencies to increase welding speed and accuracy for bipolar plates without introducing defects.

About Civan

Civan Advanced Technologies Ltd. was established in 2008 and is the only company to offer dynamic beam lasers. Civan’s dynamic beam lasers allow manufacturers to control beam shape, frequency, and sequence and to focus steering, eliminate spatter, increase welding power, and increase speed. Through their advanced capabilities, dynamic beam lasers open the door to countless new applications. Visit Civan at CivanLasers.com.

About Smart Move GmbH

Using mathematical models of the motor and mirror combinations built into scan heads, Smart Move has created the most powerful digital state space controllers on the market, enabling customers to overcome the limits of conventional scanning solutions. Smart Move has provided the fastest and most accurate scan heads available worldwide for more than 20 years.