Bending the Rules: Press Brake Technology Helps Turn New Operators into Forming Experts

Innovations in press technology are pushing down the barriers for new operators to learn metal forming and making the process of training new operators safer and more productive.

Posted: January 28, 2022

THE CUTTING EDGE

By Tom Bailey

In the world of metal fabrication, tools and equipment have always combined with knowledge and experience in order to turn raw sheet stock into useful parts. Sheet metal working machines are critical to the factory process, but so are skilled and well-trained fabricators. In this world where tools and techniques meet and mingle, one area of activity tends to stand out in terms of difficulty compared to the rest: forming.

It’s something of a cliché in fabrication circles that press brakes are some of the most complex factory machines to setup and operate, and therefore skilled and experienced press brake operators are some of the most sought-after individuals on the factory floor. Training new operators, even with great mentorship, is a lengthy process and likely to result in scrap and rework being generated until the trainees reach a level where they can be productive. On top of the amount of knowledge required to be successful running a brake, there are the safety concerns that come with introducing people to a new mechanical process where a mistake or momentary inattention can quickly result in on the job injuries.

Manufacturers of press technology have worked steadily during the last years to improve this picture. As the machines become more precise, able to hit the same position repeatedly even when the frame is subjected to tremendous tonnage load, it becomes easier for operators to produce consistently accurate flanges. As integrated machine safety systems move from the realm of “optional add-on” to “standard equipment,” the process of operating press brakes has become safer and press-related injuries less common. Meanwhile, software improvements to the press controls, as well as advances in the sophistication of offline programming systems for bending machines, have made getting new bending jobs into production faster and more efficient. And along with these improvements, the shift toward precision-ground, segmented bending tools has made setting up press brakes faster and more ergonomic.

Advances Benefit Both New and Incumbent Operators

The advances haven’t stopped there, either. New innovations in press technology are pushing down the barriers for new operators to learn metal forming and making the process of training new operators safer and more productive than it’s ever been. These advances are also helpful for experienced operators, allowing them to leverage their skills to be even more efficient at bending. One of the simplest of these new technologies, and one of the most helpful, is the tool setup indicator. Although this feature has existed on presses for some time, it is becoming more commonplace. Consisting of a strip of LED lights mounted to the tool clamp on the press brake, usually recessed beneath a hard cover to protect from accidental damage, the tool setup indicator shows the press operator exactly where the bending tools for the current job need to be loaded into the press. Once tool setup is complete, the tool setup indicator can help guide the operator through the bending sequence, by lighting up over the current active tool station for each step in the bending program. When paired-up with an optical safety system that can identify the profile of the bending tools loaded into the machine, this technology can make setting up a new job on the press brake nearly foolproof, even for a brand-new machine operator.

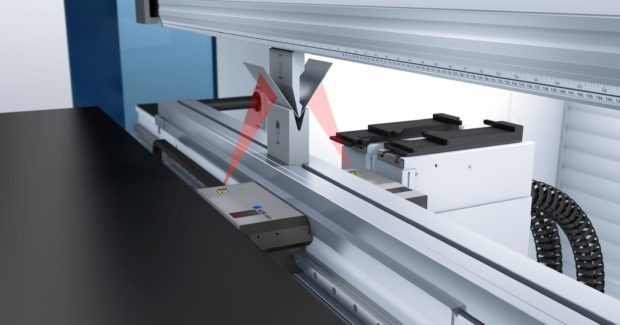

Another technology that is not new but keeps advancing in capability and ease-of-use, is active angle measuring. A number of different systems have been devised by press brake builders to help regulate bending angles on-the-fly. The impetus for this development is, of course, the fact that sheet metal as a raw material is notoriously inconsistent. Not only can thickness and tensile strength of sheet metal parts vary from one batch of material to another, or from one sheet to another, these parameters can also vary within a single sheet. For example, most rolled metal sheets are slightly thicker in the middle than at the edges, due to the slight deflection of the rollers under pressure during the sheet-making process. Likewise, tensile strength and elasticity of a material will depend on how the grain of the sheet is oriented, meaning even within a single part there can be bends that require different settings to produce the same bending angle. Angle measuring technology aims to reduce or eliminate the effect of all this variation on the process of making bent parts. The best of these systems currently available can regulate angles down +/- 0.3°, eliminating all material variation from the outcome of the bending angle, and furthermore can do this without any setup effort or operator skill required.

The proliferation of precise bending machines, precision-ground bending tools, 3D programming software and active angle compensation technology have combined to make angular accuracy easier than ever to achieve. However, all of this technology put together cannot prevent scrap parts being produced if the operator handles the part incorrectly. It is extremely easy for inexperienced press operators, even with good instructions, to become confused about the sequence or exact positioning of a part and end up forming a flange incorrectly. And even the most experienced press operators can be fooled by a part that appears symmetrical, but in reality, is not. One slot or round hole can make an apparently symmetrical part non-symmetrical, a detail that is easy to overlook and will certainly result in a bad part being produced.

Another common cause of bending scrap is left- or right-handedness in the part. A typical scenario: A stack of 10 identical parts are delivered to the press brake operator for bending, however five of these blanks must be formed in one direction while the other five need to be formed as a mirror image, with the bends all facing the opposite way. How often does this situation result in 10 parts being bent the same way, so now we have all lefts or rights instead of an equal mix of both?

Innovations in the Press Technology Toolbox

One of the latest additions to the press technology toolbox aims to rectify this. The part position indicator utilizes a vision system integrated into the press brake, combined with some slick image processing software on the machine control, in order to ensure the correct placement of the bending part against the back gauges of the machine for every bending step. The operator of the machine is presented with a real-time video image on the press control which shows, from a top-down perspective, the bending part and back gauges as the part is inserted into the machine. A colored overlay image of the part from the bending program shows exactly how the part should be placed in order to perform the current bending step. The overlay image is colored red when the part is not properly positioned, and changes to green when the vision system detects that the real bending part is positioned correctly. The system is sensitive enough that even a single hole out of place will fail to trigger the “green light,” so even a part that is almost perfectly symmetrical can be placed with confidence and bending errors can be drastically reduced.

The sum of these technologies means that these new press brakes will be user friendly, productive, safe, and easier to train new team members on. In addition, the reduction in scrap and increase in productivity means that these new generation bending machines will be more profitable to operate than ever before. And quite possibly, the real upshot of all this advancing press technology will be that fabricators will stop looking at that press brake in the shop as the “complex,” “difficult” and “dangerous” machine and instead come to consider it the perfect machine for a new fabricator to start learning the trade. www.us.trumpf.com