BLM Group Focuses on Product Optimization and Direct Benefits for Its Customers

While metal tube processing is at the core of the BLM Group’s solutions, its expertise and in-depth knowledge of metal processing has led to a portfolio that includes flat sheet laser cutting systems, 5-axis laser cutting systems and more.

Posted: February 23, 2022

The BLM Group USA (Novi, MI) remains on the cutting edge of technology by responding to its customers’ needs. The company expects the automation component of its business to grow stronger, in particular the metal tube processing solutions. Continued investments by its parent company, the BLM Group based in Italy is generating excitement. The investments in product capabilities, facilities and people strengthens the company’s commitment to impacting the future of the metal forming and fabricating industry.

BLM Group, a global leader in tube and sheet metal processing solutions, offers fabrication equipment and products that allow job shops to focus on process optimization and efficiencies in their processes. In the past couple of years, a steel supplier has benefitted from these advantages. The BLM Group USA’s team assisted the steel supplier with its market diversification efforts. The company added fabrication equipment internally in response to an OEM customer’s request that they conduct the fabrication work within their shop. The steel supplier purchased a tube laser cutting system and tube bending machine from BLM Group at the end of 2020 and into early 2021. As of this writing, the company plans to buy an additional bending machine, and perhaps two or three more bending machines before the end of 2022.

The value of the addition of the fabrication equipment by this steel supplier to its service capabilities creates opportunities. By taking this leap the company can meet a customer’s requirements, attract new business opportunities, and change its financial outlook.

Responding to the Evolution of the Market

New opportunities and developments are ever present, and the BLM Group is positioned to respond. The marketplace is coming out with more creative and custom profiles of tubes for their products, incorporating even more sleek and efficient designs. The BLM Group’s products allow users to process nonstandard structural shapes of nonstandard square tube, rectangular tube, round tube, as well as elliptical to aluminum extrusion profiles, said Gunar Gossard, the North American sales manager for BLM Group USA.

For example, the BLM Group USA has been heavily involved in the projects of an exercise equipment company. The company experienced quite a boom in 2020 and 2021 when the COVID-19 pandemic sent people home to work and play as gathering places shut down. The exercise equipment company spent quite a bit of time in design. “Our machines have allowed them to continue to manufacture using the tools, laser tube and tube bending, to take advantage of fun and crazy designs that the consumer wants to put in the corner of their home,” Gossard said. The resulting exercise equipment is sleek and visually pleasing and not an eyesore.

During that same time frame, people were investing in boats, ATVs and power sports “toys” because they were unable to travel due to COVID-19 restrictions. This meant more boat and trailer manufacturing was taking place. Gossard said BLM Group’s machinery provided advantages to manufacturers who needed to process longer lengths of tubing for the manufacture of boat trailers, which assisted in speeding up their processes and meeting their customers’ demands. “And it really changed their outlook for the future based on this technology and what it can do for them,” Gossard said.

Storied History in Tube Processing Solutions

BLM Group USA opened in Novi, Mich., in 2000-2001 with its first four employees. At the time, the company primarily focused on laser tube cutting systems and hydraulic tube bending equipment. Prior to the bricks and mortar presence in Novi, BLM Group’s machines were sold in the United States through an importer. The BLM Group is a manufacturer of machine tools that started in the 1960s in Cantu, Italy, north of Milan. The company created the world’s first automated tube laser cutting system that came from a saw, Gossard noted. From there the company evolved from cutting round tube to cutting rectangular tubes, and other profiles of tube.

A few years later, the company transitioned its tube bending equipment from hydraulic to all electric. “That was a big change in the market and [we are] really technology leaders surrounding those two markets and bringing those [products] to our customers,” Gossard said. “And we continue to build on that.”

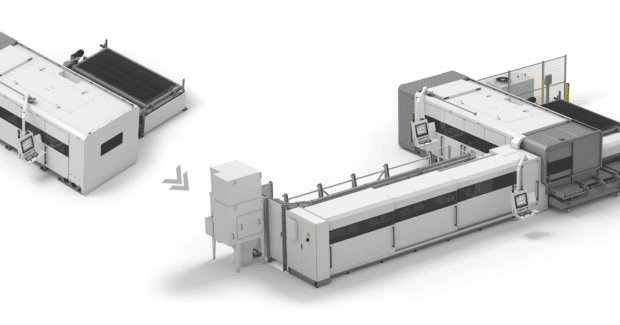

BLM Group USA also offers a combination machine that features flat sheet laser cutting and tube laser cutting, which its parent company had initially sold in the European market. The company then expanded its roster with a flat sheet laser cutting machine.

Fast forward to 2008 and 2009 when the BLM Group introduced the world’s first fiber tube laser and continues as the market leader in this technology.

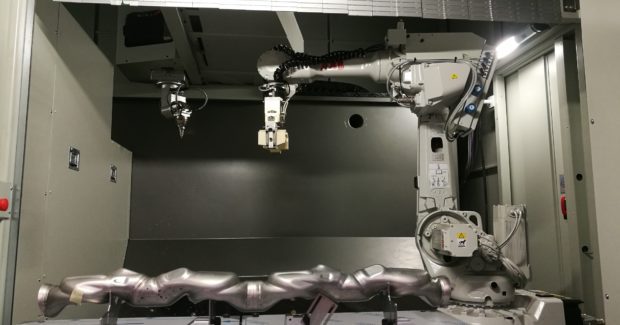

In 2017, the BLM Group redesigned its 5-axis laser cutting system, which can handle any type of three-dimensional section, and can be equipped with two robots to handle workpieces. What’s more, in 2019, BLM Group introduced its first press brake to the North American market.

Gossard pointed out that while BLM Group’s market share regarding laser tube machines has always been strong, the company needed to be more present in the flat sheet machine marketplace, proactively reaching out to new customers. The company continues to develop and advance flat sheet equipment to assist shops as they respond to customer requests to expand their product offerings and reduce lead times. These shops need to both produce and control products they may once have outsourced to suppliers and BLM Group offers shops the complete package of fabrication capabilities.

“You know, the flat sheet market is very competitive,” Gossard said. “Our competition has continued to get stronger in all products and we continue to get stronger in all products. Iron sharpens iron.” Offering a full slate of fabrication products to assist its customers shows up in the BLM Group’s bottom line, which continues to see record levels of sales and revenues. “We can see a direct tie to that growth by diversifying our product line but also maintaining our market share in what our original products were, on that laser tube and bender side,” Gossard noted.

Automation and technology are driving product development and initiatives, which spans from automation with flat sheets to the tube lasers. Gossard noted that tubes are different animals than flat sheets and users increasingly want to automate the loading and unloading processes on tube benders using some form of robotics. “Is it all clear and fine-tuned?” Gossard asked. “No. But the demand in that request continues to come up and I think for everybody in the industry it continues to be an important factor in our product offerings.”

During the span of Gossard’s career in the metal fabrication industry (23 years in fabrication equipment, with nine plus of those years with BLM Group) he has witnessed several changes. One change is where OEMs and corporations require job shops to provide the complete component systems. Shops that started off offering flat sheet cutting and press brake bending have added laser tubes and a variety of equipment, for multiple reasons, to meet their customers’ needs, Gossard noted.

Companies are also engaged in continuous improvements to reduce both lead times and costs. And naturally the technology component of the metal fabrication equipment sector continues to evolve, beyond advances in equipment. Machine operators want to operate $1.5 million machines from their handheld devices. They also want that user interface and multistep processes that are automated functions to make things simpler.

Gossard also noted the evolution of technology in providing service to customers such as the ability to remotely access and run diagnostics on machines to solve problems. Industry 4.0 technologies are widespread in the metal fabrication industry and equipment manufacturers factor these technologies into their products. Shops are all about the data they can collect from their machines.

Dynamic Times

There are several factors at play regarding the future of the metal fabrication industry such as supply chain constraints and labor challenges. Gossard expected 2022 will be a strong year for job shops as they meet the demands of their customers.

As such, the automation component is increasingly important in solving challenges because there are questions about what the labor force will do. For example, BLM Group heard from customers throughout 2020 and 2021 that they needed to buy another machine to be operational in the first shift, even though they had the capacity for a second and third shift, because they were unable to find operators. Equipment manufacturers will continue adding capabilities to machines so that they can run unmanned and meet customers’ production needs with the capabilities they have, Gossard added.

What else is on the horizon for this fabrication equipment manufacturer? “I am excited about the automation component that will continue to get better and expand,” Gossard said. “It has been very present in the flat sheet side of things.” Automation advances will continue on the tube side of the equation and BLM Group has already designed solutions and will continue to improve on them.

Gossard also noted the importance of customer service and communication, such as the implementation and utilization of remote diagnostics for troubleshooting machinery. “We understand that is a necessity and a big part of manufacturing and what customers need,” Gossard said.

BLM Group also plans to continue as the marketplace leader for its core product line, as well as continue responding to customers’ requests. “It is fun to be part of that growth and the future within BLM,” Gossard said.

Worldwide Leadership Position in Tube and Sheet Metal Processing

BLM GROUP was founded in the 1960s in Cantu, Como, Italy by Pietro Colombo. Today, the family-owned and privately held company has an international presence, including BLM Group USA, based in Novi, Mich., which provides tube processing solutions to the North American market. The BLM Group employs 755 people worldwide. Its product line includes laser tube and flat sheet cutting, cold sawing, bending, end-forming, end-machining and wire bending machines.

Colombo passed away in December 2018 and his children, Emanuela and Paolo Colombo, are committed to global leadership in tube and sheet metal processing solutions, as well as expanding product lines. Over the years, the company has created thousands of applications in the development of tube and sheet metal fabrication equipment; expertise job shops can depend on.

For complete details, visit www.blmgroup.com.