Leave the Fumes Behind

Our individual health, and employee retention efforts are improved with new technology to clean the air in our facilities.

Posted: February 3, 2022

It’s that time of year again. The overhead doors have come down and the air quality in many manufacturing plants has suffered a serious setback. Working in a fume-ridden environment wouldn’t rank high on any employee satisfaction survey, and yet conditions like this are all too common.

Years ago, this was simply considered part of the job. But not today. The old way of doing things is no longer acceptable. Younger generations of tradesmen are thinking twice about jobs with poor working conditions — conditions that could pose long-term health issues. We must strive to get better, not only for our collective health, but also to attract talented employees and tradesmen that we are in such dire need of today.

According to federal OSHA for fiscal year 2020, Respiratory Protection (29 CFR 1910.134) ranks No. 3 of the top 10 most frequently cited standards following worksite inspections. While this standard doesn’t only apply to welding fumes, it is one of the more common contributors. Poor conditions left unaddressed, and employees subjected to prolonged exposure, the risk of developing health complications such as occupational asthma, pneumonia, manganism, and even cancer, grows.

Much thought and discussion has been given as to how to attract new talent into the trades. However, how does the industry retain talent when it is leaving for safer, healthier conditions? One way is to increase workplace safety standards. In the welding industry, most of that focus would be on the improvement of air quality.

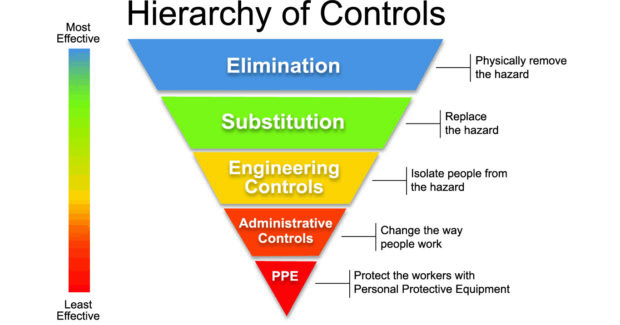

Controlling direct exposure to respiratory hazards is the primary method for protecting workers. The Hierarchy of Controls (Figure 1) is a frequently used guideline for determining how to select and implement exposure control solutions.

While there are different solution levels ranging from the least feasible (elimination of the welding fume) to the least effective for the protection of all exposed personnel (PPE for all employees), the implementation of well-designed engineered control systems for weld fume mitigation is the best overall strategy.

There are several ways to combat weld fume exposure. A common method is the introduction of various configurations of Welding Hoods. These are one of the most effective static solutions for automated, and in some cases, manual welding applications. The cost of ownership can be significant due to the typical need for high airflow rates, large filter area, big motors and fans, ducting, etc. If improperly designed, these solutions can struggle to maintain safe exposure levels, especially with competing in-plant air currents.

Portable Extraction Arms are a common solution. They do a wonderful job capturing the fume when properly positioned. If the fume source is stationary, much like with welding hoods, they are ideal. However, if the fume source frequently moves (i.e., large, welded components), the extraction arm must be repositioned for each weld. These engineered solutions are easy to apply and are very flexible, but they require operator diligence to work consistently.

Downdraft and/or Backdraft Systems are also common solutions for weld fume mitigation. They are a good weld fume capture solution for small to medium parts. They also work very well for other metalworking processes. However, they are often dimensionally limited. Some components cannot be positioned on the table. Also, if you are welding too high above the table, weld fumes can escape. They are very application specific.

Welding and Grinding Booths are also a potential solution. They contain the work area and use “regain” air to establish flow across the booth, directing fume and dust to the extraction filters on the opposite side. They are extremely effective, yet costly. In plants where floorspace is limited, they may not be feasible.

Ambient Air Filtration Systems are growing in popularity in many manufacturing plants. Rather than capture the fume at the source, they allow the fumes to rise and stratify well above the breathing zone. At that location, the ambient systems push/pull the air back and forth across the plant, filtering [air] in the process. Combined with a good source-capture fume extraction solution, ambient systems provide an added measure of security to ensure excellent air quality.

High-Vacuum Source Capture Systems are staking their place as the go-to solutions for many fabricators. When able to capture the fume directly at the source (i.e., within inches of the arc), the benefits of doing so become compelling. Lower airflow rates, smaller filtration systems, simpler and lower cost ducting, cleaner operator breathing zones, and easy compliance with OSHA regulations are among a few of the key benefits of a properly designed high-vacuum system.

After years of development, FumeVac is the clear performance leader in the high-vac segment of the industrial air filtration industry and offers the following products:

- ErgoMax™ MIG guns

- Automatic torch products

- Robotic source-capture systems

- Portable extractors

- Large-scale central extraction systems for multi-gun installations

Whether you are a large manufacturer or a smaller fabrication shop, the future of smog-free air is here to stay.

For more information go to www.fumevac.com.