Precision Results: How to Select the Right TIG Torch for You

By understanding the distinct types and features of TIG torches, as well as expendables and the workpiece, you can pick the perfect torch that suits both the job and your work style.

Posted: February 23, 2022

When it comes to TIG welding torches, some things never change, just like a good “cult classic.”

That’s not to say manufacturers aren’t constantly innovating and upgrading torches for better performance and increased user comfort. They are, constantly.

There are, however, things that never change with this industry-standard product, one that helps welders lay down precise and spatter-free welds at a slower pace with superior results.

No matter how many advancements torch manufacturers make to air- or water-cooled torches, TIG operators can be assured that the nomenclature will always stay the same for each level of torch they use.

Air-cooled TIG torch styles are named 9, 17 and 26 series, while water-cooled ones are called 18 and 20. This standard nomenclature has been around for years, so if I talk about a Series 9 torch, welders will immediately know what I mean.

Amperage rates for these industry-standard torches also have remained constant over the years. For air-cooled TIG torches, 9 Series are rated for 125 amps, 17 for 150 amps and 26 for 200 amps. With water-cooled torches, the 20 Series are rated for 250 amps and 18 Series for 350 amps.

While the torch names and amperage ratings for each never change, manufacturers, however, continually unveil new torch innovations to ensure operators get the precise results they seek, efficiently and ergonomically all for premium performance with every weld.

Because TIG welding is so meticulous, you must be comfortable using your torch for extended periods. These torches also need to stay cool and be small enough to manage with control and precision, even at high amperages and duty cycles.

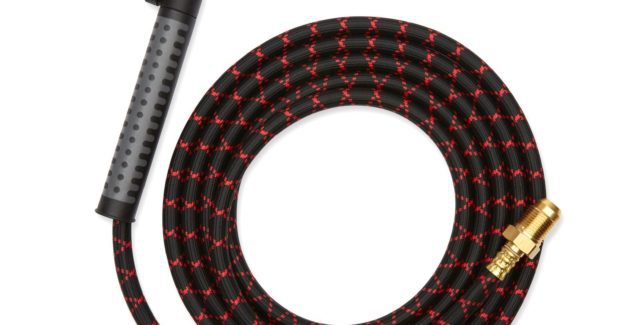

Over the years, manufacturers have tweaked torch design with these factors in mind. Reducing the handle barrel’s diameter provides operators with a firmer grip and added torch control. A more flexible cable makes work easier, as long as it also delivers the expected amperage and shielding gas performance. Durability is important, too. That’s why all internal components and expendables hold up under regular TIG use.

Choosing the right TIG torch and expendables is a highly personal, and sometimes overwhelming, decision in the world of TIG welding. What torch you use is up to you and the workpiece in front of you. However, there are key questions to ask determining how to select the right TIG torch for you:

- What’s my project?

- What’s the required amperage?

- How long of a weld am I running?

For example, larger joints and longer runs mean higher heat levels. More heat requires a larger torch and perhaps even a water-cooled option. It all depends on the job’s overall needs.

A 9 Series torch, the smallest TIG torch, is ideal for tight spots. The 17 Series is a great all-purpose torch that covers all the basics of a traditional TIG welding setup. These air-cooled torches, along with the 26 Series style, are popular because they are easy to use, offer good cable management and more hose-to-torch ratio. They run up to 200 amps, depending on the model. You can push past their duty cycle ratings, but for longer jobs, you need to consider the two water-cooled options, the 18 and 20 series.

Once you select the torch that works best for you, you’ll need to select a torch head from several distinctive styles and sizes. You have three options — the standard rigid head that comes with your torch, a flexible head or a flexible valve head.

The standard rigid torch head works with TIG applications requiring simple joints. If you need to reach into unnatural joints or corners or get a weld around a bend, try a flexible head. It’s better for unique joint options and is a popular option to have in your arsenal of TIG tools.

Flexible valve heads have the same flexibility as the regular flexible head but also feature a small screw valve in the torch that controls gas flow. When you use power sources without an internal gas solenoid, such as engine drive welders, you can attach this kind of torch directly to the gas bottle. You then use the valve rather than the traditional TIG foot pedal.

We can talk about features and specs all day but finding the right TIG torch comes down to what works for you. We compare the process to finding the perfect baseball glove. Everyone likes a different fit and style. What works for your coworker might not be the right option for you. By understanding each type, its features, related expendables, as well as the workpiece, you can better select the perfect torch not just for the job but for your work style and comfort.