Superior Products Extend the Lifespan of Tools

Long tool life is a critical component toward ensuring your shop remains competitive.

Posted: February 3, 2022

Tooling manufacturers continue to develop unique and innovative products to prolong tool life in the most challenging operations. These high-quality tools improve accuracy and cutting performance, which reduces waste, saving you precious time and money.

Comprehensive End Mill Line Cuts Virtually All Materials; Ideal for Universal Applications

EMUGE-FRANKEN USA, (WEST BOYLSTON, MA) a leading manufacturer of high-performance end mills, taps, thread mills, drills, and other rotary tools, has significantly expanded the range of TOP-Cut VAR, its most popular multi-purpose high performance end mills. Featuring unique geometry and coating, TOP-Cut VAR end mills are the most versatile variable helix carbide solution in the industry, as equally effective in multiple job shop applications as they are in challenging production cutting operations.

The TOP-Cut VAR line is now available in 4,5, and 6-flute configurations, with or without corner radius, and ball nose, stub, standard and long lengths in inch sizes — more than 300 SKUs in total. The company can also provide custom variations or tool modifications of its TOP-Cut VAR mills.

“Our TOP-Cut VAR tools are the best choice for manufacturers who need flexibility and performance,” said Dan Doiron, EMUGE-FRANKEN USA Milling Products Manager. “In addition, we are now manufacturing these end mills at our North American headquarters in West Boylston to stringent EMUGE-FRANKEN Germany specifications and standards.”

The TOP-Cut VAR end mills feature unique flute and profile geometries optimized for long tool life and superior performance in both roughing and finishing applications. Variable helix angle flutes provide extensive vibration dampening and are precision ground with advanced edge preparation to maximize chip evacuation. A chamfer feature protects cutting edges to prevent chipping, and end mills with fully blended corner radiuses extend tool life, while providing improved surface finishes. All end mills feature an advanced ALCR PVD coating that enables extended life in higher operating temperatures. A proprietary sub-micro grain carbide provides maximum abrasion resistance and durability.

A Connection That Won’t Let Go

To reduce the time involved in setting up equipment and production lines, JW Winco (New Berlin, WI) has incorporated a new coupling in its product portfolio. With the GN 1050 quick release coupling, components can be quickly and securely connected to a machine or device with just a click.

The quick release fastener consists of two elements: the coupling GN 1050 and the tailored threaded stud GN 1050.1. A safety locking button protects the coupling from being accidentally opened. When pressing the button, the sleeve can be moved axially to unlock a stud inserted into the notch on the inside. At the same time, a red ring becomes visible on the outside to indicate the unlocked state.

The quick release coupling is available in two designs. Version F has a fixed bearing for precisely positioned attachment; and version L has a loose bearing permitting a certain degree of tolerance between the fastening points.

The quick release coupling comes standard in black anodized aluminum and a locking mechanism made of zinc plated steel. The high-quality materials and surface finishes effectively protect against corrosion and wear and sustain axial connection loads up to 7868 lbf (35 kN).

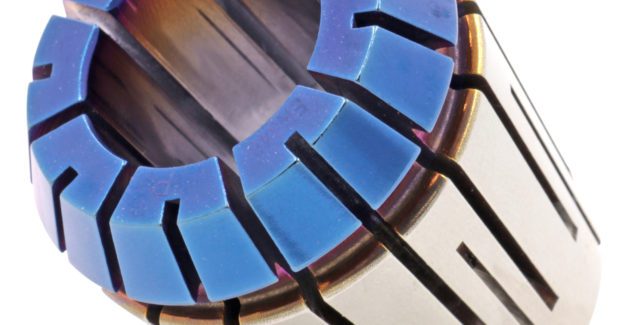

World’s First Coated ER Collet

Parlec (Fairport, NY), part of the Techniks Tool Group, has released the new P3 ER collet system, the first coated ER collet system. Parlec’s P3 ER collets feature a special anti-friction coating on the 30° face of the collet that interfaces with the collet nut when tightening during tool setup. The anti-friction coating reduces radial distortion helping improve runout. The P3 ER collets have a repeatably accuracy of 0.0001” and are sealed for coolant pressures up to 2,000 PSI due to a special slotting design. The collets are available in ER11, 16, 20, 25, 32 and 40 inch and metric sizes. P3 ER collets may be used in any ER collet chuck to improve accuracy and cutting performance.

New High Feed Square Cut Size 14 Milling Systems Tackle Difficult-to-Machine Materials

Seco Tools LLC (Troy, MI) has launched a high feed cutter and insert series in size 14. It increases tool life and maximizes the value of every edge with this new series in stainless steels, titanium, and superalloys milling applications. The High Feed Square Cut size 14 milling system is ideal for tough materials and comes in a full range of Seco Tools grades made to achieve fully secure and optimized high-feed milling.

The single-sided, straight edge insert geometries allow users to push high feed milling speeds to new limits. Ensuring high feed per tooth whether ramping, pocketing, plunging, or performing face or copy milling, this new solution creates great chip evacuation and makes it easier than ever to manage difficult machining operations or milling in deep cavities.

Not only does this solution make it easier to machine sticky materials, but it is designed for easy, ergonomic indexing and the pocket and screw designs simplify positioning. The cutters themselves feature a new environmentally friendly coating and their outstanding high feed milling performance reduces the amount of power used in roughing.