Yaskawa Webinar on Feb 23: Develop Patterns for Common Handling Tasks

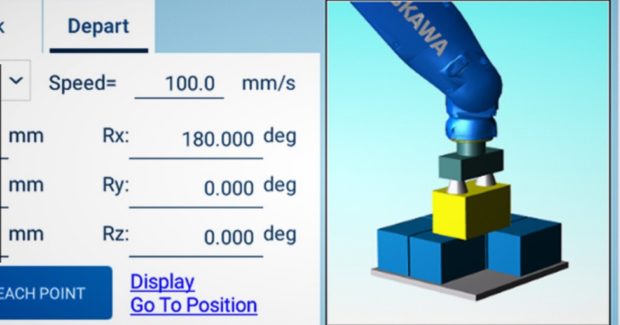

Learn how the easy-to-use Smart Pattern version 1.01 – a graphical interface for the Yaskawa Smart Pendant – provides a user-friendly way to create a pattern-based handling program.

Posted: February 15, 2022

(Miamisburg, OH) Motoman helps discover a faster way to develop patterns for common handling tasks! To bolster operations, manufacturers are turning to advanced technology, including robotic automation, improving inefficiencies for greater productivity gains. While traditional robot programming is sometimes confusing or difficult, intuitive tools are bridging the gap.

Register to learn how the easy-to-use Smart Pattern version 1.01 – a graphical interface for the Yaskawa Smart Pendant – provides a user-friendly way to create a pattern-based handling program. Join Yaskawa Product Manager, Chris Caldwell, as he explains and demonstrates why this product is well-suited for stacking, unstacking, case packing, machine loading and more.

Highlights:

- Overview of the current industrial landscape

- Discussion on the need for fast pattern generation

- Introduction to Smart Pendant

- Deep dive into the easy-to-use Smart Pattern interface

- Single part, grid (2D array), 3D (3D array) and stack patterns

- Pattern jobs vs. Supervisor jobs

- Job editing for specific system requirements, and job file export

- Robot and controller compatibility

- Gripper and end-of-arm tooling recommendations - Demo on how to set up a pick/place pattern using Smart Pattern

Who Should Attend:

- Manufacturers looking for an easier way to manage common handling applications

- Yaskawa customers that currently use a robot with a Smart Pendant for handling, packaging, palletizing or other repetitive pattern-based tasks

About the Presenter:

Chris Caldwell is Product Manager at Yaskawa Motoman, where he is dedicated to product planning and execution throughout the product life cycle. This includes responsibilities for gathering and prioritizing product and customer requirements, as well as defining the product vision and working to ensure customer goals are met. With over 15 years of experience in manufacturing and operations, he has worked in every corner of organizations to provide exceptional products and services, while optimizing costs, maintaining reliability and ensuring quality. Chris holds a BS in business management from Wright State University.