High Speed, Accurate and Easy to Use Measurement and Inspection Tools

Thanks to the latest innovations in M&I, your shop can easily conduct high levels of quality assurance.

Posted: March 24, 2022

New Touch Probe Offers Extraordinary 3-D Machining Accuracy and Speed

HEIDENHAIN’s (Schaumburg, IL) new TS 760 touch probe is for use with contouring TNC and other major CNC controls. It is distinguished by extraordinary 3D accuracy making it especially useful during 5-axis machining and more. The new probe offers extremely high accuracy (±1 µm) and homogeneous switching behavior over 360°. And for 3D measurement, the feed rate/probing speed of 1 m/min is four times faster than other commercially available products that offer the same impressive repeatability of (2σ ≤ 0.25 µm). The ultra-low trigger force of (≈ 0.2 N; axial: ≈ 1.5 N) eliminates form and surface damage. What’s more, the probing point can be cleaned with the integrated flusher feature by using compressed air and cooling lubricant of up to 60 bars. The TS 760 is fully compatible with HEIDENHAIN’s TS 740 predecessor and provides the same additional data as the TS 460.

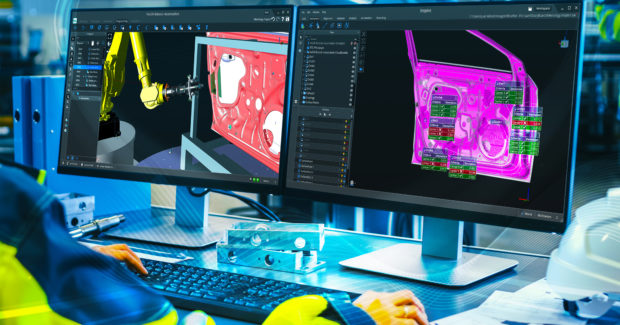

Platform Accelerates Autonomous Quality Assurance for Industry 4.0

Hexagon’s Manufacturing Intelligence division’s (North Kingstown, RI) HxGN Robotic Automation is an open robotic control software platform that enables non-specialists to code and control any industrial robot to democratize industrial automation. HxGN Robotic Automation enables manufacturers to accelerate adoption of Industry 4.0 by intelligently devising optimal inspection routines in a single step; a task that typically involves both a metrology and robotics professional.

Built on open design principles, the software interfaces with any new or existing industrial robots and is flexible so that quality professionals can employ the most appropriate metrology sensors to help rapidly future-proof factories with real time, inline metrology. The measurement data is used to optimize production in real time, enabling faster, self-correcting manufacturing and freeing up staff time for other tasks, such as data analysis.

HxGN Robotic Automation supports Hexagon laser trackers, Leica T-Scan and AS1 scanners and directly interfaces with FANUC and KUKA robots while built-in postprocessors enable the robot controller to work with a wide range of third-party robots.

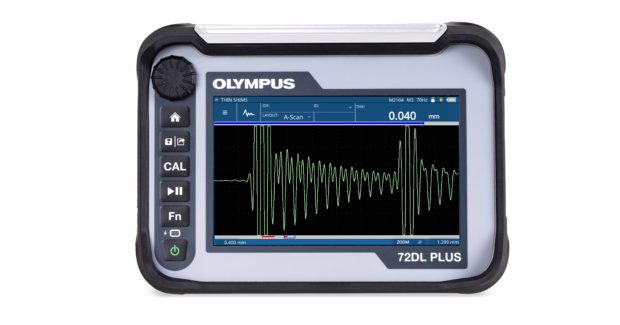

Thickness Gauge Measures Ultra-Thin Layers and at High Speed

The new Olympus (Waltham, MA) 72DL PLUS™ ultrasonic thickness gauge delivers precision thickness measurements at high speed in a portable, easy-to-use device. With fast scanning, advanced algorithms and Olympus’ lowest-ever minimum thickness capability, the gauge can measure the thickness of very thin layers for challenging applications across industries. Whether used to gauge paint, coating or material thicknesses, the new instrument delivers reliable, lab-quality measurements.

Capable of displaying up to six layers at once for multilayer coatings, paint, plastics and other materials, the gauge includes five measurement layouts so thickness changes can be accurately tracked and visualized. For routine applications, inspectors can store and recall settings to simplify device setup before each inspection. Built-in data logging and onboard file management provide streamlined thickness data collection and processing, while the PC Interface Application includes intuitive tools to review and manage data for multiple devices and parts. The gauge supports wireless LAN, Bluetooth®, and USB connectivity and integrates into the Olympus Scientific Cloud™.

Built for industrial environments, the gauge can be used indoors and outdoors or on a work surface; it also meets meets military drop test standards (MIL-STD-810G). It is also designed to meet IP65 requirements to protect against dust and moisture and has an operating temperature range of –10°-to- 50°C (14°-to-122°F). The gauges are available in standard and high-frequency models. The latter can drive transducer frequencies up to 125 MHz to measure ultra-thin materials — including multilayer paint, plastics, metals and coatings — and simultaneously display the thickness of up to six layers.

www.olympus-ims.com/en/72dl-plus/