Optimize Your Metal Fab Processes with the Next Gen Machinery and Software

Learn the latest product developments in bending, cutting, pressing, stamping and the software to support these processes.

Posted: March 24, 2022

Newly Designed High-Volume Press with Unitized Frame

AIDA-America, a metal stamping press manufacturer located in Dayton, OH, offers the newly designed NSX mechanical stamping press. This 110-metric ton, unitized frame press, runs at speeds of 120-to-300 SPM with a stroke of 65 mm. Locally engineered at AIDA-America, the NSX features a low deflection, one-piece frame and a low deflection cast iron slide.

High-volume production is assured by using zero clearance roller type slide guides and counter rotating eccentric shafts. Press and die integrity are preserved with the inclusion of hydraulic overload protection. The press’s floor mount design, intended to be paired with isolation mounts, as well as choice of plug and play Wintriss, Link, or Rockwell Allen-Bradley controls, provides ease of installation. The eight programmable limit switch channels are standard. The applications of this press will benefit the automotive, appliance, hardware, and consumer goods markets, among others.

Ascent™ Line of Pre-Engineered, Configurable Hydraulic Presses Now Available

Beckwood Press Co. (St. Louis, MO), a leading manufacturer of custom hydraulic and servo-electric presses, automation systems, and the Triform line of precision forming equipment, now offers the Ascent line of standard, high-quality hydraulic presses. The presses are pre-engineered and can reduce cost and lead time by up to 50% compared to custom presses without sacrificing quality or performance. With models ranging from 30 tons to 500 tons and 21 different frame sizes, the Ascent line offers an array of choices for manufacturers and job shops of every size. Each press features a unitized gib-guided frame that provides superior guidance and rigidity. Speed, stroke, daylight, and shut height are fully configurable to the customer’s exact needs. Options for heated platens, HPU configurations, and safety equipment add flexibility to the line. As with all Beckwood presses, the Ascent line is built in the USA, engineered for Infinite Life using Finite Element Analysis, and backed by the company’s robust service and support team.

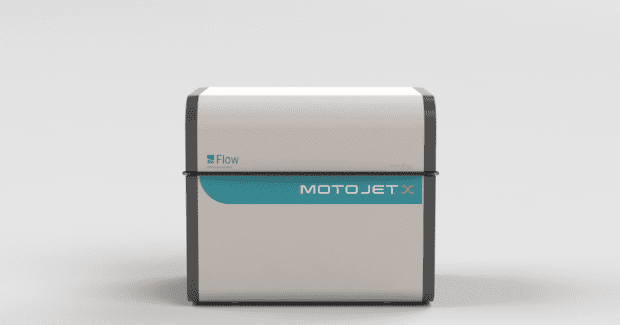

Flow Releases Industry’s First Long-Life Intensifier Pump

Flow International Corp. (Kent, WA), the world’s leading developer and manufacturer of ultra-high-pressure waterjet cutting systems, offers the next generation of intensifier pump technology, the MotoJet X. Its advancements focus on maximizing customer uptime, improving usability, and nearly eliminating hands-on customer maintenance.

The MotoJet X features ultra-quiet operation with a sound deadening design. It comes with easy access points with quick-remove side panels, an air-assisted lid, and an automatic interior light. The status light is built directly into the lid handle, providing quick visibility to the operating status of the pump, and comes IoT enabled and smart connection ready.

The MotoJet X operates at 60,000 psi with both 30 hp and 50 hp options and is compatible across the entire Flow Mach Series of waterjet solutions.

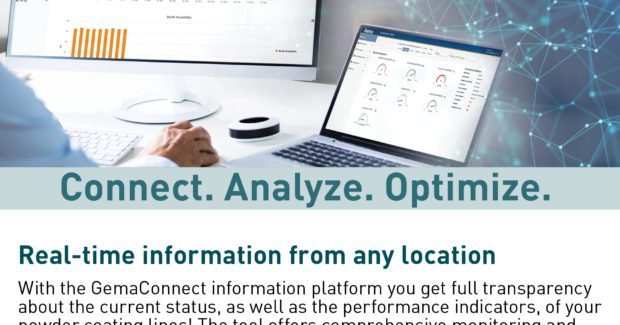

Visualize, Analyze and Optimize Your Powder Coating Process

The GemaConnect from Gema (Indianapolis, IN) is an interactive program that provides users with full visibility of the status and Key Performance Indicators (KPIs) of their powder coating equipment, regardless of location or time. The web-based tool is continually updating and storing powder coating data for comprehensive monitoring and analysis from a single source. Users can access their customized data via the GemaConnect dashboard, allowing them to visualize and analyze their KPIs. Using this information, users can make quicker and more informed decisions on improving their powder coating process performance.

With GemaConnect, users can put customized indicators and favorites on their screens, allowing them to keep critical areas in view. The interactive platform also provides historical information about the performance and utilization of the plant, as well as relevant process parameters.

Automated Gantry-style Hydraulic Press from Greenerd

Greenerd Press & Machine Co. (Nashua, NH) offers unique hydraulic press application solutions, including an automated 30-ton gantry-style hydraulic press, which was built for an application requiring precise positioning of pins. A linear transducer mounted in the press cylinder enables a minimum depth to be programmed into the control to ensure proper pin depth has been achieved. The 25′ long hydraulic press features automated gantry positioning with optical recognition of the distance between each set of pins to be inserted. The cycle can be initiated in an autonomous operation where the gantry moves to each pin location and applies the set of tonnage on the pins.

Hypertherm Renames Waterjet Pumps

Hypertherm (Hanover, NH), a U.S.-based manufacturer of industrial cutting systems and software, has rebranded its HyPrecision™ and Echion™ waterjet pumps as DynaMAX™ to unify the naming of its intensifier pumps. HyPrecision pumps now have a black exterior to match the exterior of the Echion pumps, and their industry leading features and benefits will remain the same. All Hypertherm intensifier-based pumps will continue to be differentiated in the market by:

- Best-in-class performance and ease of service from market-leading Advanced Intensifier Technology™.

- More consistent hydraulic and cutting pressure from a closed-loop proportional pressure control.

- Advanced Intensifier Monitoring that allows customers to better plan for service.

- Fluid management system to ensure water and oil don’t leak on the ground.

- The industry’s lowest maintenance costs for intensifier-style waterjet pumps.

New Alum-Renew Kit Quickly Restores Aluminum

Madison Chemical (Madison, IN) introduces the Alum-Renew Kit, a combination of four cleaning and surface preparation products that remove various surface contaminants from aluminum substrates. Users can quickly and effectively remove grease, oil, metal chips, coating carbide spots, light oxides, weld marks, carbonaceous films and similar contaminants that commonly occur during the various stages of forming and fabricating aluminum. Each kit contains a gallon of VISCOCLEAN GREEEN alkaline detergent, along with aluminum conditioners of varying intensities: ALUMA-SAFE GEL (mild), ALUMA-CLING-BLUE (moderate), and TREADBRITE EDGE GEL (aggressive). Alum-Renew is ideal for any OEM that is forming, fabricating, or otherwise manufacturing components with aluminum substrates. It is also well suited for field repair work and refurbishment.

Using the Alum-Renew prior to painting improves even distribution of high-performance resins through reduction of surface irregularities. The kit allows users to try products of varying intensities before purchasing selected materials in production quantities.

Enclosure Series Ensures Total Protection Against Dust and Continuous Submersion

Mencom (Oakwood, GA) offers a range of IP68 series rectangular enclosures that provide the highest level of protection against dust and complete, continuous submersion in water. These enclosures have also successfully passed the tests required for the IPX6 degree of protection (tightness to powerful waterjets) and for the IPX9 degree of protection (high pressure and temperature waterjets). Therefore, their official overall protection rating is IP66/IP68/IP69.

In order to achieve an IP66/IP68/IP69 rating, the design of oil and fuel resistant NBR elastomer O-ring seals played a key role. The first O-ring seal is fitted around the mating edges on the base and the second O-ring seal is in a slot inside the base. The unique dual O-ring seal design helps maximize waterproofness between the hood and base. When installing the enclosure on the cabinet panel, an optional mounting frame with four M6 threaded blind holes may need to be installed inside the panel to ensure waterproofness.

The IP68 enclosure series is larger than standard enclosures, providing more space for easier cable management, and the walls are thicker to provide more mechanical robustness. The enclosures also use two different locking systems, bayonets and screws, instead of the locking levers on the standard enclosure. The IP68 series enclosures also provide protection against electromagnetic interference and emissions.

Upgraded Gemini® Grinding and Combination/Pipeline Wheels Now Available

Saint-Gobain Abrasives (Worcester, MA), one of the world’s largest abrasives manufacturers, offers the upgraded Norton Gemini Grinding and Combination/Pipeline Wheels, which offer the best performance in the aluminum oxide wheel market today. The enhanced Norton Gemini wheels feature a new premium alumina grain for a 15% faster cut rate. Advanced bond technology and wheel hardness are designed for making fast cuts and provide up to 60% longer life and metal removal per wheel compared to previous generations.

The upgraded wheels are designed with ergonomics in mind, offering a controlled yet aggressive feel without causing fatigue. The wheels have been updated with large, industry standard icons that cross language barriers, and are an on-the-wheel reminder of proper machine selection, safe usage and required personal protective equipment.

The wheels are a good choice for grinding 400 series stainless, and hard-grade carbon steel applications including weld repairs, flashing, multi-pass welding for pipefitting and notching. Key market segments are metal fabrication and welding, as well as oil and gas/pipeline. Offhand stock removal, smoothing welds, beveling and notching are all ideal applications.

Enhanced for pipeline applications, the Gemini Combination Wheels feature a bond that has been optimized for 30° angle grinding and 90° angle notching. The wheel construction is more dense and thinner, making it ideal for multi-pass welding with tight clearances.

Clutch/Brake Provides Precise Repeatability and Control

Force Control Industries (Fairfield, OH) offers the Posidyne® size 1.5 clutch/brake, which provides precise repeatability and control even in high-cycle count environments, with no-maintenance or adjustment required. Ideal for fractional to 3 HP drives, this Double C-Face mounted clutch/brake features a multiple disc design that produces high torque from a small package, boosting accuracy, cycle rates (up to 300 cycles per minute), and lifetime (20-to-40 million cycles). The Posidyne 1.5 is ideal for machine tools, conveyers, packaging machines and other applications. The oil shear technology allows rapid and precise stopping, starting, reversing, speed change and positioning — all without adjustment and virtually no maintenance. Ideal for applications with frequent start/stop cycles, unique motion control devices allow higher cycle rates to increase production rates with lower downtime. The totally enclosed Posidyne clutch/brake is impervious to dust, chips, chemicals, coolants, caustic wash down, weather, and more, making it ideal for hostile environments, and severe or hazardous duty. Force Control Industries is the world leader in oil shear technology, offering a full line of clutches, brakes and clutch/brakes for OEMs in diverse applications.

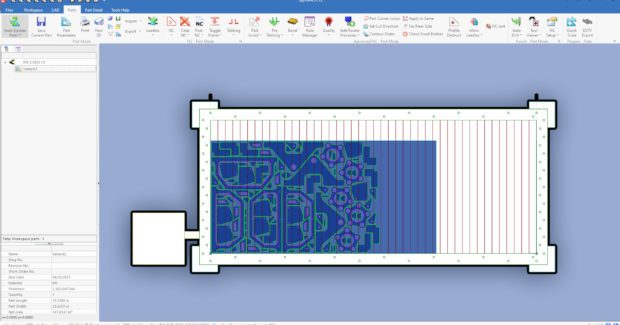

SigmaNEST 2022 Includes Several Enhancements and an Expansion of ‘Connected Shop’

CAMBRIO (Cincinnati, OH), a leading innovator in the CAD/CAM fabrication industry, offers version 22 of the SigmaNEST software suite, which includes all areas of the SigmaSUITE product portfolio, including CAD/CAM nesting for router, bevel, punch and cut-to-length. This version also expands ‘Connected Shop’ capabilities that will help both large and small fabricators.

A redesigned installer detects all existing products for upgrading. Programmers get a jumpstart with enhanced import capabilities for the latest native CAD formats, such as sketch association to SigmaNEST operations for NX, and 3D part property mapping for SolidWorks. In addition, the SigmaNEST shape library has been improved to enable super-fast parametric geometry edits for more efficient CAD programming. “Team communication is a critical part of manufacturing success,” said Glenn Durham, engineering vice president, CAMBRIO. “The need to connect all operations and track the workflow throughout the shop is growing in importance. Version 22 is a substantial release and another step towards joining the dots to ensuring our customers are best positioned to benefit from the latest technology advancements and industry drivers.”

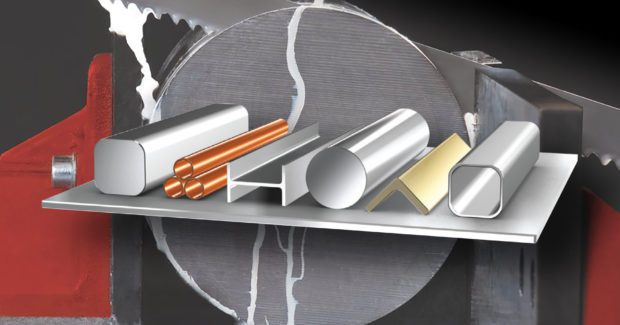

Starrett’s IntenssTM Blades and Industrial Quality All-Purpose Lubricant

The L.S. Starrett Co. (Athol, MA) offers Intenss Bi-Metal Band Saw Blades for general purpose metal sawing of a wide range of materials and shapes. Featuring a patented process developed by Starrett called bi-metal unique® technology, which provides 170% more weld contact with the teeth, the blades exhibit superior resistance to tooth strippage, significantly reducing fracture and breakage. Performance is further enhanced by M-42 teeth with a multi-edge tooth design that produces split chips for faster cutting.

Bi-metal blades are available in 1/2″, 3/4″ and 1″ widths and .025″ and .035″ thicknesses. Blades in 1-1/4″ or 1-1/2″ widths and .035″ and .042″ thicknesses are also available, without the bi-metal feature. Intenss blades are available in pitches of 10, 14 or 18, and 2-3, 3-4, 4-6 and 5-8 variable pitches. Coil lengths are available in 100′ (30 m), 150′ (45 m) or 250′ (75 m), depending on blade widths.

Starrett also offers M1® Industrial Quality All-Purpose Lubricant, ideal for metal equipment such as rollers, racks, conveyors, chains and virtually any metal components found in highly corrosive environments such as marine, general metalworking and more. M1 is not soluble in water so it gets under moisture to lift it away from the surface to be protected. Starrett M1 Special Formula Lubricant protects metal against rust and corrosion damage by providing a molecular shield that locks to the metal. The lubricant can be used to protect working surfaces of machinery, in dip tanks to protect production parts in process, or apply on tools when stored.

The lubricant dries and will not attract dirt, dust or other contaminants and produces a micro-thin, airtight coating/film that simultaneously dries as it protects. M1 is free of silicone, making it an excellent lubricant to stand up to extreme temperatures for year-round use. Its deep-down penetration works quickly to free frozen nuts, bolts and metal parts, and it gets under caked-on dirt. It also removes grease, tar, and grime from metal parts and painted surfaces, cleaning and polishing for lasting protection. The lubricant is available in 53-gallon drums, one- and five-gallon containers and 12-ounce aerosol cans.

New Programmable Limit Switch for SmartPAC PRO Press Automation Controller

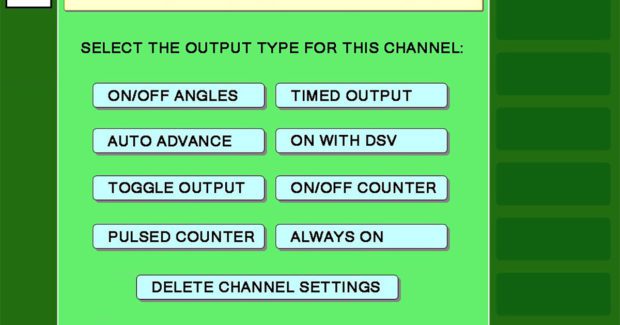

Wintriss Controls Group (Acton, MA) offers a new ProCamPAC PRO Programmable Limit Switch (PLS) for its flagship SmartPAC PRO Press Automation Controller. Building on the proven functionality of the ProCamPAC PLS, the new PRO PLS features five additional cam timing options that provide unprecedented flexibility and functionality. The Wintriss SmartPAC PRO Press Automation Control integrates programmable limit switch, die protection, clutch/brake control, tonnage signature analysis, and automated setup of counterbalance and shut height into one control.

The new ProCamPAC PRO PLS includes the Toggle Cam Output, which performs an asymmetrical toggle function, turning an output off or on for different stroke amounts. The output can be used to operate diverter gates and to control complex gagging operations. The new On/Off Counter Cam Output precisely controls functions that need to operate at a preset interval instead of on every machine cycle. Operating similarly, a new Pulsed Counter Cam Output is programmed with an “on angle” and a dwell time instead of an on/off output.

Useful when running configurable tooling, a new Channel Always On Cam Output will simply turn on and stay on until a new tool is loaded. A unique Triggered Cam Output actuates a precision one-time cam timing signal based on a preset trigger such as an external input from ancillary equipment, an extended period of machine idle time or a job change. This output type is ideal for diverting parts during a warm-up period, QC checks or when bad parts are determined by an outside measuring system.

New Flap Disc is Ideal for Contoured and Edge Work Applications

WALTER Surface Technologies (Windsor, CT) offers the new Type 29 ENDURO-FLEX TURBO™ flap disc. With a higher ergonomic angle of attack, the new Type 29 flap disc allows for a fast removal rate best suited for heavy-duty applications such as blending contours, edge work, as well as other finishing applications. Save a valuable step in your finishing process thanks to the ENDURO-FLEX TURBO’s unique dual grit 36/60, made from self-sharpening ceramic which removes material quickly and leaves a paint-ready finish. The patented Turbofan™ design minimizes heat transfer to the surface, which increases the disc’s life. By funneling in air, it keeps the workpiece cooler, reduces discolorations and improves disc durability. All ENDURO-FLEX TURBO flap discs are balanced allowing for a vibration-free application and a comfortable operation, which reduces worker fatigue. They also comply with ANSI B7.1 standard.

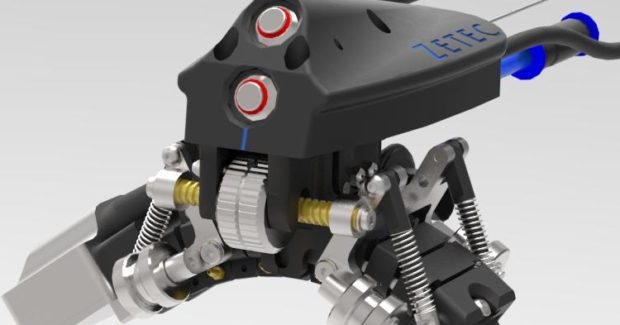

New UT Scanner Ideal for Ultrasonic Testing of Pipe Elbows

Zetec’s (Snoqualmie, WA) new ElbowFlex scanner is ideal for fast, manual ultrasonic testing of pipe elbows, delivering high-resolution C-Scan images of flow accelerated corrosion and other types of wear without the need for conventional UT pencil probes and grid systems. The scanner’s 1D flexible linear array probe will adapt to diameters from 4” NPS (4.5”) to flat. It stays concentric throughout the inspection for a fast, efficient scan with a high probability of detection. ElbowFlex weighs 2.5 pounds and features simple button operation and magnetic wheels.