Rocklin Manufacturing’s Turnkey Automation Solution for Hard Surface Coating

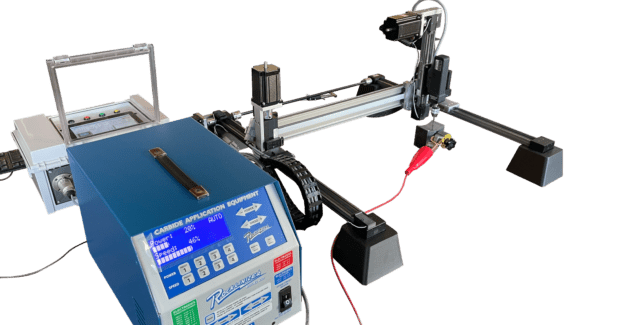

The solution is part of Rocklin’s Rocklinizer® carbide application equipment line, Rocklinizer® Automation.

Posted: March 28, 2022

Rocklin Manufacturing (Sioux City, Iowa) introduces the first turnkey automation solution to its Rocklinizer® carbide application equipment line, Rocklinizer® Automation.

The company’s proprietary Rocklinizer® spark deposition process applies extremely hard and wear-resistant coatings onto steel surfaces to extend machine life, cut downtime, delay capital expenditures, reduce inventory, and optimize grip. These results are typically achieved through a handheld, manual coating process. Now, with the introduction of Rocklinizer® Automation, manufacturers can cut costs through wear-resistant coatings while also freeing up precious time and resources to pursue other value-added tasks. In today’s challenging labor market, this innovation drives an even greater return on investment from Rocklinizing.

Three Simple Steps to Automation

Rocklinizer® Automation involves a minimal investment of time and cost, with only three simple steps to achieve precisely controlled deposits ranging from .0001” to .010”:

- Measure and position your part to be coated in the large X-Y frame.

- Insert the electrode into the applicator and adjust the Rocklinizer® power and speed to your desired levels.

- Input the part dimensions on the integrated touchscreen PC and trigger the coating process.

Unlike welding or metal spraying, minimal heat is generated, and the electrode material will not separate or flake off. After Rocklinizing, no heat treatment, grinding, or other surface treatment is necessary.

Boosting Productivity While Easing Labor Challenges

The Rocklinizer® solves a wide array of wear and gripping problems, including:

- Boosting grip on tube bending dies, collets, and robot grippers

- Minimizing die casting wear

- Eliminating slug pull back in punching and stamping

- Restoring tolerances in bearings and shafts

- Increasing the life of cutting tools

www.rocklinmanufacturing.com/rocklinizer/