Take Advantage of Short Cycle Times and Accurate, High-Precision Machining

Progressive and innovative metal-cutting machines and software speed up your processes by reducing cycle time and enhancing productivity.

Posted: March 24, 2022

ANCA FX5 Gets a Power-Boost

ANCA (Wixom, MI) has upgraded the FX5 Linear 2-wheel pack machine with a new grinding spindle rated at 12 kW peak power as well as releasing a high-powered spindle option of 19 kW. CNC tool grinders strive to achieve the shortest possible cycle times — to keep the cost per tool produced at a minimum. Machine performance and grinding cycle time are linked to the power capabilities of the grinding spindle.

To maximize material removal rate, a commonly accepted industry practice is limiting the spindle load to between 30% and 40% for fluting operations. If the spindle load is likely to exceed 40%, tool manufacturers tend to allow for a second fluting pass as this contributes to longer wheel life and less wheel load. Auto white-sticking becomes an important option as batch sizes increase. ANCA has conducted a spindle load analysis of fluting operations, identifying how many passes are recommended in relation to spindle load. The analysis compares two flute endmills ground with either 6-, 8-, 10- or 12-mm diameters. The new FX5, which has now been upgraded from 9.5 kW to a 12 kW spindle, can comfortably grind tools up to 10 mm diameter in a single pass. A 12 mm tool required a second grinding pass to keep the spindle load at 40%, rather than increasing to 60%.

This is where the new high-powered 19 kW spindle option makes all the difference. The 12 mm endmill was ground at a 40% spindle load in one pass, with an overall time saving of one minute and four seconds — opposed to two passes at 12 kW. Customers will benefit from the increased spindle power provided by the new 12 kW standard spindle on FX5 and now have the option to purchase their new ANCA FX5 with a high-powered spindle, adding more flexibility in the tool room. Most importantly the high-powered spindle reduces the production cost and increases net output across a wider range of tools. The use of “One Pass Productivity” for tools with 12 mm diameter translates into an increased output of 15.8% — with 70 tools produced in an eight-hour shift compared to 60 tools with the new standard 12 kW spindle.

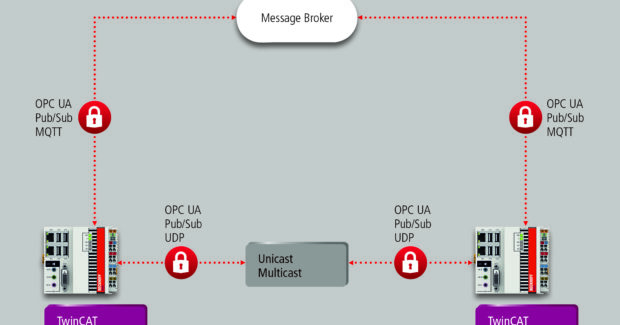

Software Directly Integrates OPC UA Pub/Sub

Beckhoff Automation (Savage, MN) provides real-time-capable data communication via OPC UA with the new TF6105 function in its universal automation software. The new function offers direct integration of OPC UA Pub/Sub communication into Beckhoff’s TwinCAT 3 runtime. This new capability establishes straightforward and secure machine-to-machine (M2M) and device-to-cloud (D2C) scenarios based on the OPC UA Pub/Sub specification.

With a new extension of the OPC UA specification, which Beckhoff played a prominent role in helping develop, the publisher/subscriber principle is introduced into the established and standardized OPC UA communication protocol. Two different transport paths are defined in the specification for data transmission: UDP and MQTT. UDP enables efficient and real-time-capable data exchange in a local network between machines or machine components. Transport via an MQTT message broker primarily, but not exclusively, supports cloud scenarios.

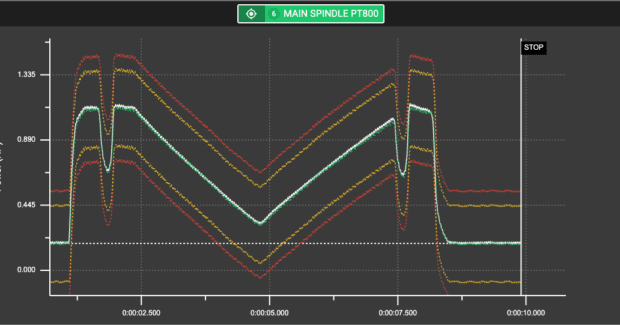

New Signature Analysis for Constant Surface Speed Cutting – CNC Machining

Caron Engineering, Inc. (Wells, ME) offers a new signature analysis feature for CNC machining to accurately monitor the exact path of a tool in cut. The feature has been added to Caron’s TMAC (adaptive tool monitoring system) and DTect-IT (sensor/software monitoring suite) products. This capability is specifically beneficial for constant surface speed cutting operations, which have historically been difficult to monitor due to the varying spindle rpm as material is removed. Signature analysis allows for the monitoring of cutting processes where the material diameter changes consistently during a cut. The rpm varies as the material increases or decreases causing sensor fluctuations unrelated to the tooling. Signature analysis software learns the entire path (signature) of a cut using any sensor type. The user defines a window where the signature must stay within to satisfy a good cut. An alarm is generated if any portion of the signature of a monitored tool extends beyond the upper or lower boundary. It is a time-based analysis, so a consistent start time matching the cutting start time is crucial to success.

In manufacturing, this applies to such constant surface speed cutting as facing and turning operations on a CNC lathe, where the rpm is being adjusted automatically to maintain a proper chip load. The lathe starts cutting at the original diameter of the part and as it removes material, the diameter is consistently decreasing. Those rpm changes cause a spike in power which is difficult to monitor with typical tool monitoring. By learning the signature of the cut and setting boundaries around the learned signature, these cuts can be accurately monitored to ensure optimal surface finish.

KAAST’s 5-axis CNC Vertical Machining Center

KAAST Machine Tools, Inc. (Aldan, PA) presents the V-Mill 600.5X, a 5-axis CNC Vertical Machining Center, which utilizes a massive gantry structure consisting of a base frame, double racks, and stable crossbeam to ensure rigidity and cutting performance. This model also features cooled ball screws combined with high quality linear roller guides and a powerful, high-speed spindle with ceramic bearings for superior milling surface. The generously sized worktable diameter of Ø600 mm (23”) and is capable of supporting up to 400 kg (880 pounds). T-shape machine structure with matching column base width. The table is independently installed on the base and is fully supported through the entire stroke. This machine offers high speed for maximum stability, high precision mold and die machining.

A 30-tool magazine for flexible milling and drilling applications is a standard on the V-Mill 600.5X. It can easily accommodate BT-40 shank and includes a precision CAM drive that achieves ± 0.08 mm (0.0032”) positioning accuracy. Tool changing is a fast, smooth, stable motion and the tool change arm is completely waterproof, preventing coolant from entering the arm during use. Users also have the option of adding a pallet changer to save time with loading and unloading.

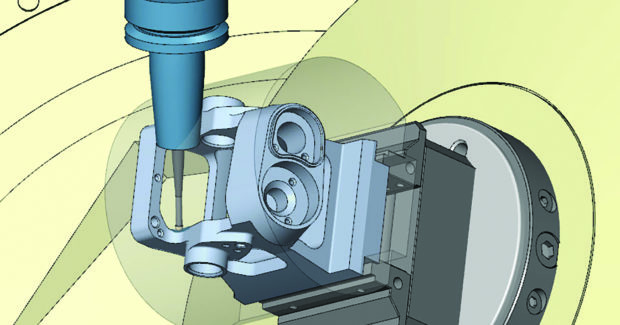

Multiaxis Machining Improves Productivity

Multiaxis machining can dramatically increase a shop’s competitiveness. Mastercam (Tolland, CT) Multiaxis is an add-on for Mastercam Mill 3D, Router 3D, Mill-Turn, and Mastercam for SOLIDWORKS®. It improves productivity with simultaneous 4- and 5-axis machining capability for Mastercam. Mastercam Multiaxis offers a wide range of multiaxis machining strategies, both basic and advanced; the toolpaths are also useful for advanced control of 3-axis machines. The new Multiaxis Unified toolpath allows you to select multiple pieces of input geometry to generate the toolpath pattern. Using those geometry choices, the toolpath picks the best algorithm to calculate the path. This single toolpath gives you access to all the surface-based toolpaths, as well as the geodesic toolpath options, in a single interface.

New deburr toolpath enhancements include a new option called number of cuts along edges, which allows users to add multiple cuts to the deburr toolpath, rounding or flattening edges, to create a quality edge on deburred parts. Additionally, the new tilt range options allow users to limit tilt when machining type is set to 5-axis (simultaneous) or 3+2 axis.

The Controlling Climb and Conventional Cutting function now provides control of climb or conventional cutting while working with surfaces that may require using both sides of a tool, which was previously impossible to maintain while cutting a curved shape that would require the use of both sides of the tool.

Swarf Milling toolpath enhancements include the drop tool to floor option that controls whether Mastercam will drop the toolpath down to a floor or retract to the bottom of swarf surfaces. The new sorting spiral multi cuts option allows multiple slices to be output as a spiral instead of single slices, providing a better finish across the part.

Rotary Advanced toolpath enhancements include the axis offset option that allows the user to shift the tool off-center to maintain a better contact point, which extends tool life and improves the machining quality. The new smoothing options round sharp corners using a perfect of the stepover.

The Mastercam Simulator includes the new Smart Measure feature that allows you to measure distances quickly and accurately in the graphics window during simulation. The simulator now processes standard 3-axis and 5-axis operations faster when backplotting, verifying, or simulating, and now lists all collisions, proximity alerts, and axis overruns in the new report pane.

www.mastercam.com/solutions/multiaxis/

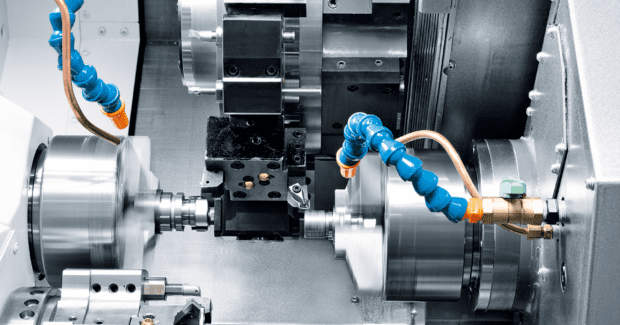

Reduce Your Cycle Time and Cost per Piece with Superimposed Machining

Methods Machine Tools, Inc. (Sudbury, MA) has released the Nakamura-Tome SC-100X2, which is a twin-turret multitasking machine that utilizes two tools on either side of the upper turret for superimposed machining, making it a logical solution for Swiss-style parts greater than 25 millimeters in diameter. Superimposed machining lets shops take on complex contracts and more jobs — all while completing them in a fraction of the time — compared to other machining methods. With simultaneous machining capability, machine shops can reduce their cycle times and ultimately reduce costs.

Operators can also use the upper and lower turret simultaneously, turning the SC-100X2 into a true twin spindle/twin turret machine, providing even more ways to solve complex machining problems. The unique design contributes to faster cycle times compared to other machining strategies. The SC-100X2 automatically unloads the workpiece once complete, minimizing manual intervention and downtime. When the machine completes a cycle, the parts catcher grips the part and places it on a conveyor, removing it from the machining environment. Nakamura-Tome’s user-friendly software allows you to program superimposed and multi-turret jobs as easily as single-turret operations, all accessible from a familiar FANUC 0i-TF Plus control.