ATI Industrial Automation’s Trailblazing Bodes Well for the Future

Leading developer of robotic accessories and robot arm tooling solutions is well suited to serve the emerging robotic surgical and electric vehicle markets.

Posted: April 19, 2022

Last year was an immeasurable year in the history of 33-year-old ATI Industrial Automation, Inc. as it became part of the Novanta Inc. family. The combination of the two companies strengthens product offerings for the most demanding robotic and automation applications. ATI Industrial Automation, Apex, N.C., entered the acquisition by Novanta as the world’s leading developer of robotic accessories and robot arm tooling. Its robotic end-effectors focus on tool changing, material removal and force/torque sensing. Novanta develops and manufactures drives, motors, encoders and actuators that enable precise motion, and is a leader in mission critical technologies to medical and advanced industrial equipment manufacturers.

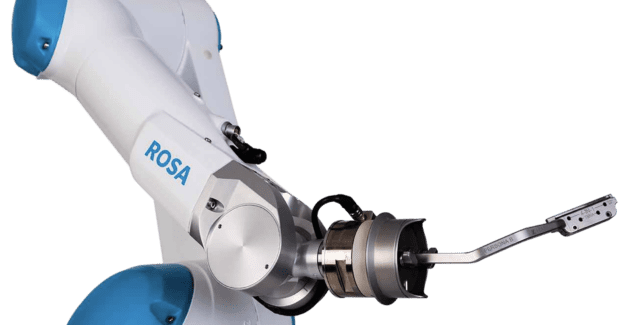

Novanta was attracted to many aspects of ATI Industrial Automation’s production portfolio, particularly opportunities within the robotic surgical segment of the medical industry. For the past few years, ATI Industrial Automation has developed force/torque sensors for use in surgical robots, which is a rapidly growing market.

“Beyond the product synergy of the two companies there was definitely a strong alignment or synergy of high-quality engineered solutions to high growth markets,” said Evan Haley, Director of Global Sales for ATI Industrial Automation. With the combined cultures and missions of the organizations the goal is simple: “We want to be the best in class and win with our customers,” Haley said. “That is key.”

Currently, ATI Industrial Automation continues to hire employees and has more than 400 plus workers. Novanta is headquartered in Bedford, Mass., with global locations. ATI Industrial Automation is busily converting former office space to create shipping space at its new-ish building, which opened three years ago. The shift allows the company to move its existing shipping space to create new space for manufacturing activities.

Solutions Engineered for Robotic Productivity

ATI Industrial Automation was started by a small group of engineers who formerly worked for the LORD Corp., a manufacturing and technology company. In 2010, the company transitioned to an Employee Stock Ownership Plan (ESOP). Robert Little, one of the founders and the president of ATI Industrial Automation, was the company’s primary owner along with the company’s employees, before the purchase by Novanta.

ATI Industrial Automation’s product line began with the production of six-axis force/torque sensors and eventually migrated toward robotic automation, producing robotic end-effectors. The company’s main product lines include: robotic tool changers, six-axis force/torque sensors, and automated material removal tools, Haley said.

Regarding the robotic end-effector products, simply put, an end-effector is a tool mounted to the axis 6 flange of a robot, and it can be used to couple with other tools or may be the tool used in the application. “In our case, the robotic end-effectors we make are typically mounted to the robot and couple to another tool that the robot is using,” Haley said.

“For example, a tool changer could be used to change multiple types of robotic tooling, such as a material removal tool and a material handling tool in a metal finishing application.”

A robotic tool changer has two pieces: the robot side and the tool side. The robot side connects to the robot and the tool side connects to an item such as a welding gun. Haley provided an example of spot welding in automotive manufacturing. The user can be doing a spot weld on to the car or part of a component on that car and will need to drop off the welding gun to a fixed location. The robot side of tool changer remains mounted to the robot, next the robot moves to pick up a new tool by coupling the master to the new tool side. This allows the robot to pick up that tool and continue working. “So, our tool changers are enabling our customers to use a single robot to multitask,” Haley said.

The robotic tool changers come in two main groupings: standard series for small payloads ranging from 1-to-200 kilos. The heavy-duty line handles payloads from 200-to-2,000 kilos. “We have a strong portfolio of tool changers,” Haley said. “All are capable of handling the payloads that our customers, working in numerous industries, need to be able to pick up in a repeatable and reliable manner each and every time.”

ATI Industrial Automation’s original product line and mainstay is the six-axis force/torque sensors. The device measures the outputting forces and torques from all three Cartesian coordinates (x, y and z). A typical use would be the insertion of a drive shaft by a robot into a transmission. The force/torque sensor guides the robot while inserting the shaft. If the shaft makes contact with the transmission housing, the sensor will provide force feedback data to the robot and the robot will move in the appropriate direction to free the drive shaft and allow the process to continue and successfully complete the insertion process.

“I believe the force/torque sensor line has the strongest synergy with Novanta regarding the robotic surgical market,” Haley said. When using a six-axis force/torque sensor combined with the haptic and vision systems of a surgical robot, the surgeon is granted the sense of sight, touch, and feel which allows them to perform sensitive procedures with successful outcomes. This results in less invasive surgeries, more accurate incisions, and faster recovery times with less risk to patients — not to mention less risk to the surgeons and the hospitals.

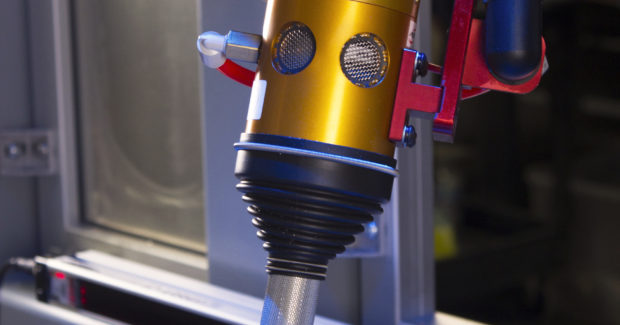

Haley said ATI Industrial Automation’s third main product line, robotic material removal tools, are ideal for use in a variety of industries. For example, in metal fabrication whether it is in a foundry, automotive or aerospace components or anything where metals require finishing. “We have developed a line of tools that work with either radial or axial compliance and work with a robot to do a specific task on a specific material,” Haley said. “And we partner with great companies like 3M to help us find ways of providing the best finishing media for the customer’s application so they get the best results possible.”

Promising Future

Haley said, “ATI Industrial Automation’s team is constantly innovating to produce better and faster products while reducing costs whenever possible. As new technologies and/or new manufacturing concepts are introduced globally within the many industries we serve, our team partners with customers to develop the next generation of products.” In some cases, Haley noted, “We go to our customers before they are even looking for that technology, so they can investigate the technology and gain an advantage. ATI’s engineering groups collaborate with customers to fine tune and/or customize our products so customers can take part in that new technology or new concept in order to remain competitive and meet their goals.”

ATI Industrial Automation’s engineering groups and leadership teams are also hard at work supporting their customers by providing solutions to navigate the impactful short-term changes at work in the manufacturing sector. For example, overcoming hiccups in the global supply chain, as well as boosting production efficiencies in the evolving electric vehicle sector.

While there are any number of reasons behind the challenges within the supply chain, one issue is the incredibly high demand for products and not enough labor to produce them. “Automation combined with robotics is going to help companies meet their demands and increase that throughput and provide a higher quality and repeatable process that gives you a better product in the end,” Haley said. “That should ideally, in time, make you more profitable and allow you to reinvest in your business. And at the same time provide a safer working environment.”

Haley said ATI and Novanta’s products are well positioned to provide their customers with solutions. “We have really done a lot to ramp up hiring and building faster, better, and finding new ways to get product out the door sooner,” he said. “We too suffer from those same supply chain challenges that everyone else is suffering from, so we understand the challenges our customers are faced with.”

ATI Industrial Automation’s team is also working closely with traditional automakers as these manufacturers transition from producing internal combustion engines to electric vehicles. “We are also partnering with automotive startups such as Rivian, Lucid and Tesla to help them meet their production requirements,” Haley said. “The short-term solutions will evolve into long-term processes as these automotive companies work to reach electrification goals set in the next decade. One of the biggest challenges everyone is facing right now is the speed of deployment of these new EV Programs as the automotive OEMs shift from ICE vehicles to EV vehicles into their new and existing production lines.

“As an example, GM launched 12 programs last year, which is an incredibly high number in a single year and the amount of work generated by these programs is just tremendous,” Haley continued.

Further, electric vehicles require changes in materials, such as the use of more aluminum to support the need for lighter-weight vehicles. “There are alternative ways of joining material where ATI makes very specialized products that helps customers utilize our tool changer to be successful,” Haley said. “Very particularly designed tool changer utility modules enable for flow drill screwing, self-piercing rivets, adhesive dispensing, high-current welding, and more.” These joining process changes support the production of lighter-weight electric vehicles so “they can travel farther and more efficiently,” Haley noted.

Haley noted that in general, the future of metal fabrication and manufacturing is great with expansion in industries such as aerospace and automotive. “The use of robotics and automation is key to our success,” Haley said. “It is crucial that companies within the Americas spend more and focus more on robotics and automation to help achieve their goals and bring business back to the Americas that allow us to compete on a global stage.”

Haley continued, “ATI and Novanta will continue to research those markets for future technologies and concepts that will improve ATI products and help our customers win.”

Customers as Partners

ATI Industrial Automation works hard at innovating and improving its products to better serve its customers. “We really want to try and give the customer the best possible product that we can and we want to do it at the fairest possible price with the highest level of quality,” said Evan Haley, Director of Global Sales for ATI Industrial Automation. “That is so important.”

Haley said the ATI team views its customers as partners. Moreover, while there are naturally tiered levels of customers regarding spending, the company treats their customers the same when it comes to fairness. “Our team truly understands that what we do is important to individual customers no matter the scale of business,” Haley said. “We are constantly developing new tool changers or associated components for the tool changer product line, new force/torque sensors and new material removal tools. We have a tremendous amount of projects in the pipeline.”

Understanding the True Cost of Automation to Realize ROI

When small- and medium-sized metal fabrication shops begin exploring the possibility of incorporating automation into their processes, the two fundamental issues center on financials, and understanding the full scope of work required to automate processes.

For example, research will find collaborative robots (cobots) range from $25,000 to $50,000, which seems very reasonable; however, this typically does not represent the total cost of implementing an automation project. Projects mostly like require additional guarding, assessments, and the possible addition of conveyors and other pieces of equipment. Experts and robot integrators should be contacted to assist in developing a robot cell or full automation cell. “There is a lot you need to understand from the mechanical aspects to the electrical aspects to the programming aspects,” said Evan Haley, Director of Global Sales for ATI Industrial Automation. Tapping into the resources of dedicated professionals ensures the successful deployment of robotics and automation in metal fabrication shops to ensure a significant return on investment in a reasonable amount of time. Profitability and increases in throughput will follow.