Cutting Edges: Smart Sawing

Innovations in band saw systems create smoother cutting machines to meet the needs of busy metal fabricators.

Posted: April 19, 2022

Double your production speeds and feeds and decrease down time when changing saw blades thanks to longer product life, as well as other technology advancements to sawing systems.

Innovative High-Performance Blades Speed up Company’s Cutting Times Three-Fold

When International Mold Steel (IMS) of Hebron, Ky., moved into its new 56,000-square-foot facility in 2019 it not only doubled its capacity but also increased its capacity for sawing systems. IMS runs saws from HE&M Saws and AMADA to produce a variety of tool steels to different markets, performing processes such as aluminum die casting, stamping, forging, and parts and machine applications.

IMS invited blade companies in for blind blade testing to evaluate blades that would allow the company to cut faster and move more products for their customers.

Through Saw Systems, Inc., a WIKUS distributor, IMS was introduced to a representative from WIKUS Saw Technology Corp. (Addison, IL), a world-leading band saw blade manufacturer. WIKUS was the only company to sit down with IMS to learn their needs and how WIKUS’ saw blades could provide solutions. (One blade company never even returned IMS’ calls or email requests.) “Wikus stood alone customer service wise where everyone else took a back seat,” said Paul Britton, president, IMS.

The WIKUS team recommended to IMS the Futura, a high-performance bestselling band saw blade; and the Skalar Premium M42, which offers high performance and extra blade life. Longer blade life results in fewer blade changes and less down time.

WIKUS’ coated blades were “what we were looking for and they outperformed everyone,” said Dave Whitley, senior saw supervisor, IMS. “We are cutting two times faster — three times faster in certain circumstances.” IMS currently uses the blades in HE&M sawing systems.

WIKUS is constantly innovating and developing solutions to provide a comprehensive range of band saw blades designed for specific customer applications. The company offers three levels of bi-metal product options so customers can select the solution that best suits their needs, resulting in cost reductions and increased productivity. The blades provide consistent and dependable reproductivity during series production.

“The first blade we tested was on our plate saw and the reason we did that was because we were cutting two cuts a day at about six hours per cut,” Britton said. “And we looked at our projections and what we needed and that wasn’t going to get it done for us. For anything under three inches thick we needed three hours a cut, max. And that is what these WIKUS blades gave us. We were able to cut our product under three inches in under three hours. Basically, we doubled our production in a single day on one saw.”

IMS next tested WIKUS’ blades on “our bigger machines that cut big block,” Whitely said. “And we doubled, if not tripled, our production out the door to pieces that were 32 square.” From that point, IMS decided to run every machine with WIKUS’ coated blades. “They outperformed every blade we put on the machines,” Whitley said.

Britton said IMS has benefited from using WIKUS’ saw blades by experiencing longer blade life, and improvements in their processes and productivity. The cost for blades went up a little bit; however, the company’s speeds and feeds have doubled, and even tripled. “For us, processing, we have gotten stuff out the door a heck of a lot faster than what we did before,” Whitely added.

HBE Series Available in Seven Models from 10 inches to 41 inches of Cutting Capacity

The HBE series of saws from Behringer Saws, Inc. (Morgantown, PA) are known for unparalleled speed and accuracy, making them one of Behringer’s most popular offerings. The HBE is a rigid, fully enclosed automatic bandsaw with solid cast iron bow-frame construction. This cast iron, produced in our foundry in Germany, is designed to dampen vibrations and contributes significantly to both cut quality and blade life of the saw. The rigid cast iron construction also maintains consistency so you never worry about strength or durability.

Engineered with safety, energy efficiency, and affordability in mind, the HBE series is excellent for applications from aluminum to stainless steel, single bars to bundle cutting, and everything between. Available in seven models from 10 inches to 41 inches of cutting capacity, they boast a variety of features making it more than “just a saw.” The ball screw servo-driven feeding gripper assures the industry benchmark in both tight and repeatable length tolerances, minimizing waste with very short remnant pieces. Precision guiding systems ensure the right cut every time, and electrically controlled chip brushes remove chips for better blade life, cut quality and cleanliness. Material feeding capabilities make maneuvering your payload a breeze. These features are just a part of what gives Behringer its legendary reputation.

A Fully Automatic Scissor Style, Mitering Band Saw

The C-510MNC is one of Cosen Saws International, Inc.’s (Charlotte, NC) most sought-after machines in the fabrication marketplace. It is a heavy-duty horizontal machine that comes complete with an extensive list of features and optional accessories. Like other Cosen SNC series machines, the C-510MNC has the capability of indexing material up to 999”and provides storage of up to 100 jobs. It is equipped with a 1-¼” blade and a 5 hp motor. Great for shops that have production runs of straight or miter cutting, the C-510MNC can achieve cutting angles of up to 60 degrees and has cutting capacities of 14” round and 13” x 20” rectangular.

An automatic horizontal scissor style, mitering band saw:

- Allows for straight cutting and miter cutting from 0-to-60 degrees

- Hydraulic cylinder supports the saw head with ball joint

- Gearbox designed to accept high lateral pressure (no thermal distortion)

- Inverter blade drive system allows infinitely variable blade speeds

- 7” HMI touchscreen

- Adjustable flood coolant system

- Motor driven, synchronized wire blade brush

- Carbide blade guides and bearings provides additional blade support

- Rigid cast-iron guide arms

- Automatic hydraulic blade tensioning device

- Cast-iron hydraulic vise

- Save-A-Blade feature

- Precision feed pressure and feed rate dual valve system for optimal cutting performance

- Computer controlled multiple indexing up to 999” max length

- Compatible with Cosen’s Q-Cut QR reader software for easier job input

Dual Column Band Saw from HE&M Features Several Enhancements

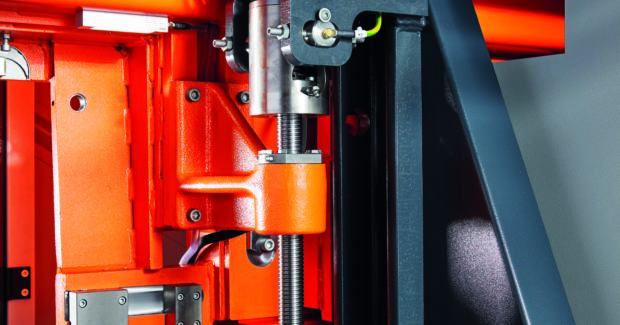

HE&M Inc.’s (Pryor, OK) DC22A is a dual column band saw designed for cutting exotic metals like Inconel and tool steels like D2. The saw uses a 2” blade with a cutting capacity of 22” W x 22” H. This new saw was designed with improvements that create a smoother cutting machine, greatly improved blade life, and make maintenance easier. The saw’s columns are now constructed of structural tubes rather than the fabricated columns on older models, creating a stouter arm configuration. The column chains have been replaced with linear rails for less arm side-play. The results are increased stability of the arm on the DC22A.

The saw has a twin ball-screw bar-feed that is servo-driven creating faster cycle times and is more accurate in positioning the material. This allows for improved efficiency and more accurate part lengths. The feed stroke is 0-to-48” with multiple indexing for longer part lengths. The bar-feed also has the option to add a third holding vise and full-capacity top clamp for additional clamping during material indexing and cutting process.

The DC22A control console has HE&M Saw’s new and enhanced Smart Saw® controls with a 9″ Omron touch screen. This new control platform is Industry 4.0 ready and compatible with MTConnect® to improve process flow and allow interaction with the equipment. HE&M Saw has invested in newer technology and integrated these advancements into its controls and systems. As a result, sensors and software are helping keep track of maintenance items and diagnosing issues faster, saving and optimizing labor resources to give customers better return on investment. The touch screen controls are clean and simple to make programming and running automatic jobs easy; and previous jobs can be saved and reloaded any time.

HYDMECH’s Newest Vertical Band Saw, the V-21/26APC

A heavy-duty vertical band saw, HYDMECH’s (Woodstock, Ontario, Canada) V-21/26APC efficiently cuts both solid and structural material and is extremely versatile for many different types of sawing applications. Featuring a large 26″H x 21″W capacity, 10 hp motor, and 1-1/2″ blade, the V-21/26APC is a reliable choice for all automated vertical metal cutting applications.

The V-21/26APC miters from 60 degrees left to 60 degrees right. Mitering is programmed with digital angle display and head tilt is controlled hydraulically. Saw head has a 4-degree-cant allowing for efficient cutting and improved blade life. Featuring a 60” bar feed, the V-21/26APC indexes material quickly and accurately, up to 60” or 120” optional in a single stroke. The shuttle carriage moves on linear bearings and is driven by a rack and pinion servo motor.

This model features an 8.5” color touch screen controller. No flipping from screen to screen, the control is interactive with messages to guide the operator and reduce the learning curve. It’s user friendly, graphical icon programming for miter cutting, making programming angles simple for the operator.

HYDMECH is a world leader in metal band saw and cold sawing solutions. Its innovative solutions are geared to meet the practical needs of the aerospace, automotive, and metal fabrication sectors, among others.

www.hydmech.com/products/v-21-26apc

One For All: An Appealing All-Rounder for Saw Users

With its KASTOwin sawing machine series, KASTO Maschinenbau GmbH & Co. KG (Achern, Germany) has developed an all-rounder. The fully automated band saws feature a wide range of applications, from machine and tool manufacture to the steel trade, automotive and aerospace engineering sectors. The saws also have an unequalled range of standard features and thus offer ideal value for the money.

The KASTOwin series consists of five fully automated band saws that cover cutting ranges from 330-to-1,060 mm. In addition, the machines are universally suitable for use with several types of steel. This series offers a flexible solution for numerous applications; and each line is designed with the same construction, while the components used are largely identical. As such, KASTO offers the saws at considerably lower prices than comparable products.

All KASTOwin band saws feature a frequency-controlled drive that enables cutting speeds of 12-to-150 meters per minute. For all machine sizes, the saw band is hydraulically tightened and looped around hydraulic band guides. High-energy efficiency results from the trimming of both the hydraulic power unit and the drives. Additionally, KASTOrespond is a new system that senses the saw frame feed movement via the ball screw spindle. The tractive forces on the tool are converted into corresponding feed movements via a software program. A screw conveyor ensures the safe, clean removal of chips. The material clamping vises with retraction unit guarantee reliable processes in automatic operation. The offcut length is just 35 mm, while the shortest possible section length is 10 mm.

KASTOwin saws also feature the touch screen SmartControl unit, which monitors and controls all relevant sawing and order parameters. Each KASTOwin saw is available with two different band widths. In addition, KASTO offers an extensive range of accessories for its machines. The KASTOwin also offers a moveable material support table for heavy workpieces and in a special version for machining tubular material. The high-performance bandsaw KASTOwin pro AC 5.6 is optimized for bimetallic and carbide blades. This helps reduce tooling costs and increases production speed and efficiency; depending on the type of blade, cutting times can be reduced by 50% or more.

New Durable 3X Power Blade Series Triples Cutting Performance

The L.S. Starrett Co. (Athol, MA), a global manufacturer of precision hand tools and gages, power tool accessories, saw blades and more, has launched a new series of 3X Power Bi-Metal Reciprocating Saw Blades featuring teeth that cut more efficiently, enabling users to make up to three times the number of cuts than conventional blades, and are engineered for use on corded and cordless saws.

The line includes blades for cutting wood, metal, multiple materials and heavy-duty cutting. Metal cutting blades are available in 4″, 6″ and 8″ lengths, in 14, 18 or 24 TPI, and have a straight shape. Multi-material cutting blades cut metal and other materials and are available in 6″, 9″ and 12″ lengths, in 6–10, 10 and 10–14 TPI, and have a tapered or straight shape. Also offered is a 12″, 10–14 TPI tapered blade that is ideal for cutting car bodies. King Cut™ 3X Heavy-Duty blades feature heat-treated teeth with a super-aggressive pitch set designed to slice through virtually any material. King Cut 3X Power Blades are available in 6″, 8″, 9″ and 12″ lengths, in 6-10, 10-14 and 18 TPI, and feature a straight or tapered shape.

1318 Band Saw Model Continues as Wellsaw’s Bestseller Since 1985

The Wellsaw (Kalamazoo, MI) 1318 band saw is ruggedly built to cut straight for years in the roughest environments. A true industrial duty machine and made in Michigan, the company stocks every part for every saw it has built all the way back to 1930.

The 1318 Model features push-button feed for simple operation that requires no special training. The blade tensioner is pre-calibrated and needs no guess work. Sawing force can be pre-set to a limit to eliminate overfeeding. This is valuable in trade schools and shops with many operators.