Helios Introduces the 90-W Configuration of the Hera 90 Gear Hobbing Machine

The Hera 90-W’s hobbing length covers nearly the max loadable part length, which eases the hobbing of long shaft parts with gears on opposite ends.

Posted: April 12, 2022

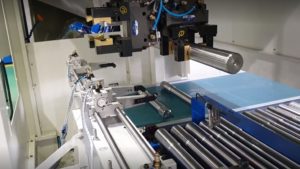

“Manufacturers have found the Helios Hera 90 CNC hobbing machine to be an extremely cost-effective, high-quality platform for 21st century gear production,” said David Harroun, Vice-President of Helios Gear Products. Evolving the Hera 90’s range of options, Helios proudly introduces the 90W configuration. This offers gear manufacturers an extended machine bed and axial travel, making the machine an ideal solution for long-shaft, small diameter workpieces. Manufacturers of powertrain shafts for small- to medium-vehicles will be interested in this machine, especially those workpieces with multiple, timed splines and/or gears.

The Hera series has been in development for over 15 years, and it continues to address the demanding hobbing needs of North American manufacturers. With Helios domestic support, the Hera 90W adds a valuable offering to the machine line by equipping manufacturers with a high-quality, low-cost, quick-delivery, domestically supported solution for long-shaft horizontal hobbing. The Helios Hera 90W is rated at 3 module (8.5 DP) for parts up to 90 mm (3.54 in) diameter. The 90W can be configured to optionally load parts up to 600 mm (23.62 in), 700 mm (27.56 in), or greater lengths. Furthermore, the machine’s axial travel (hobbing length) covers nearly the maximum loadable part length. This enables easy hobbing of long shaft parts with gears on opposite ends — especially when the gears must maintain a timed relationship. For shorter workpieces, the machine’s versatile tailstock design clamps workpieces as close as 200 mm (7.68 in) measured from the work spindle face. Other standard features of the Helios Hera 90 are included with the 90W: Fanuc CNC, complete dialog programming, 6,000 rpm hob head, high-helix cutting (for worm hobbing and milling), 160 mm (6.3 in) hob shift, bevel gear cutting, and more.

“Gear manufacturers looking for a truly versatile, future-proof hobbing machine must consider the Helios Hera 90W,” said Adam Gimpert, President of Helios. The machine’s features are industry-leading for its class: the highest part qualities can be produced for the hobbing process, turnkey solutions are surprisingly affordable, and the machine is domestically supported by Helios Gear Products with decades of proven gear hobbing expertise. Manufacturers will be hard pressed to find a better alternative.