Mixed-gas Laser Cutting Opens up Possibilities for Thick Steel Fabrication

Laser cutting with pre-mixed assist gas has been gaining traction as a fair compromise between cutting with oxygen and increasing the laser power output.

Posted: April 19, 2022

THE CUTTING EDGE

For metal fabricators working with mild steel in sheet thicknesses greater than ¼ inch, it’s long been understood that laser cutting will require the use of an oxygen assist gas and because of that, the cut parts will have an oxide layer adhered to them that will most likely need to be removed somehow. Why this is true is not immediately apparent, but it’s common wisdom among steel processing shops, nonetheless. The fact is that the chemistry of mild steel makes it resistant to the intense heat of the laser beam; a lot of this comes down to the particular iron and carbon content of the grade of steel being processed.

When using an inert gas, such as nitrogen, as the assist for laser cutting, the melting of the metal is managed entirely by the energy of that laser beam coupling or fusing with the material: The gas flow is only serving to blow the melted metal away from the cutting path. We see a different reaction when we look at mild steel because of its natural resistance to heat input. As the thickness of the mild steel increases, it becomes more difficult for the laser energy to rapidly melt through the material. At a certain point (depending on the type of laser source in use) the laser can no longer heat and melt the material fast enough to make a clean-cut edge. Slowing down the cutting process at this point doesn’t help because it creates uneven heat transfer into the material, causing deep gouges and heavy dross formation on the cutting edge.

On the other hand, when processing steel with oxygen-assist gas, we get an advantage from the interaction of the laser energy, oxygen and iron. As the steel melts under the intense heat of the laser, the flowing oxygen interacts with iron molecules in the material to produce iron oxides. The combination releases energy as an exothermic reaction: More heat is rapidly released into the cutting kerf as iron bonds with oxygen. This reaction generates enough extra heat to act as booster for the melting process, allowing the laser to power through the tough steel and produce an even cutting edge. However, as we already know, this generation of iron oxides in the cut results in parts with an iron oxide layer adhered to them. When welded over, this layer will tend to increase porosity and decrease the strength of the weld. It also has a nasty habit of flaking off when painted over, taking the paint coat with it.

Advantages of Laser Cutting with Pre-mixed Assist Gas

Although there are common methods for dealing with this edge condition (deburring machines, sandblasting, tumbling, and acid baths to name just a few), no fabricator really wants to have to do this. So, for a long time in the industry there has been a push toward higher power laser sources that can pump more wattage into the steel, increasing the thickness that can be processed with inert nitrogen and reducing the number of parts that need oxide removal. Because clean-cut edges are still the ideal goal, and higher laser powers can bring some other advantages besides processing thicker steels with N2, it’s unlikely that this trend will end any time soon. That said, there is an alternative process which has been gaining traction as a fair compromise between cutting with oxygen and increasing the laser power output: laser cutting with pre-mixed assist gas.

Manufacturers of laser processing equipment have long been interested in the effects of altering the gas composition and flow characteristics upon the laser-cutting process. One particular method, which was developed a few years ago and is now gaining popularity, is using a mixture of approximately 97 percent nitrogen and 3 percent oxygen as the assist gas for laser cutting of mild steel. This process behaves very much like a nitrogen cutting process; however, the addition of a small amount of oxygen increases the available energy in the cut. This mixture allows for the cutting speed to increase compared to cutting with nitrogen at the same laser power (as much as 30 percent faster linear feed rate) and at the same time, it reduces burr formation, resulting in a better-quality cut edge in thicker mild steels. Additionally, the extra energy of this gas mixture compared to pure fusion cutting with nitrogen allows the range of possible thicknesses we can process with our available laser power to increase. Materials that would once have needed oxygen can now be processed with mixed gas at a higher speed and with excellent quality.

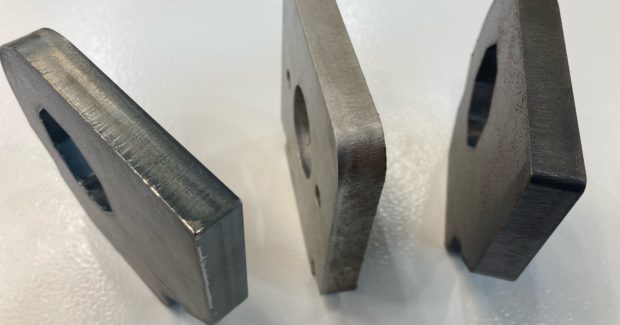

Considering all the advantages of mixed-gas laser cutting, what are the drawbacks? For one thing, it should be remembered that this is not technically a fusion cutting process although it behaves very similarly. Iron oxides are generated when cutting with mixed gas and the resulting cut edge will have an oxide layer. The oxide layer produced by mixed-gas cutting is generally thinner and more strongly adhered than the oxide layer produced by oxygen cutting; in some cases, this may mean the mixed-gas edge can be welded or painted over without any additional treatment of the edges. This does depend on the requirements of the parts in question, and in many cases, it can still be necessary to clean oxides off the parts cut with mixed gas.

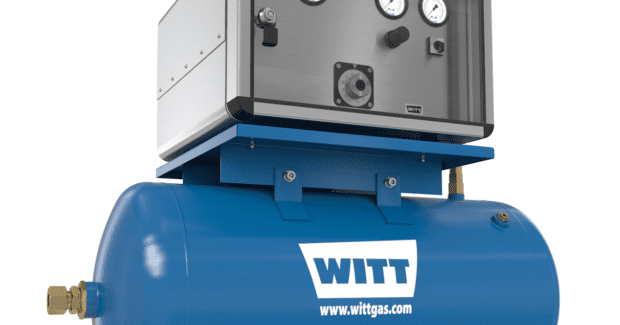

It is also necessary to invest in some equipment to support this process, however the capital cost is reasonably low. A pre-mixing device is required to provide an accurate mixture of gas to the laser-cutting machine, but the purchase and operational cost of the mixers is comparable to an industrial air compressor and the payback for the right applications is extremely quick.

All in all, mixed-gas laser cutting is a promising solution for fabricators working with a steady diet of mild steel plate, and fortunately for laser users looking to get into mixed-gas cutting, standardized solutions are available from the machine tool manufacturers that make this an easy add-on for most laser-cutting machines.