Smart Finishes: Surface Preparation and Finishing

Thanks to advancements, the steps involved in surface prep and finishing processes are fewer, and products are more versatile and safer.

Posted: April 19, 2022

Industry-leading companies are constantly improving the quality and durability of their surface prep and finishing products to ensure their products last longer. Enhancements include the ability to use just one disc for a variety of process steps. The longer product life saves your operators time by reducing steps, as well as lowering their fatigue during the finishing process.

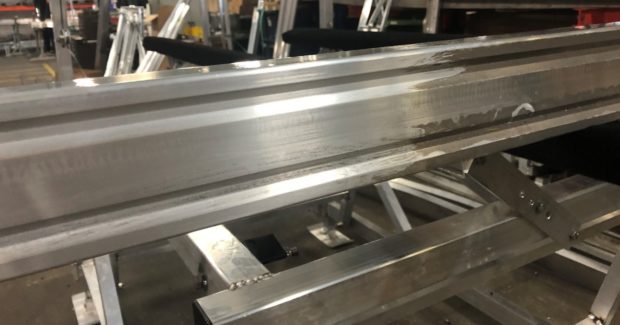

Ceramic-Hybrid Cloth Allows for Grinding and Finishing with One Disc

PLANTEX SUNFIRE CERAMIC dual-grain disc with 5/8”x 11 hub allows users to grind, blend and finish with only one disc.

CS Unitec Inc. (Norwalk, CT) has recently introduced the new PLANTEX® SUNFIRE® CERAMIC dual-grain disc with 5/8”x 11 hub that allows users to grind, blend and finish with only one disc. The disc’s 40/60 combination grit grinds like a 40, blends and finishes like a 60, saving considerable working time and extending its service life on all metals (including steel, stainless, titanium, aluminum and bronze). The SUNFIRE’s patented multigrain ceramic-hybrid grit structure provides aggressive material removal as well as controlled blending and finishing.

The disc’s ceramic-hybrid cloth flaps are adhered to a PLANTEX hemp-based backing plate. The backing plate, composed of 70% natural hemp fiber, is stronger, more versatile and safer than traditional backing plates. SUNFIRE’s high-strength construction enables longer run times, while its flexible backing plate more easily conforms to the surface of the workpiece. Suitable for a wide variety of applications, including working in tight spaces, the disc is easily trimmable and can be used to the abrasive’s last fraction of an inch. Ultimately, these discs run safer – they are fiberglass-free and produce no harsh fumes, airborne fibers or sharp pieces.

Available in 4-1/2” and 5” diameters, each disc can remove up to 9 pounds of material.

New Line of 1.3 HP Air Tools Feature Right Angle Grinders and Sanders

Dynabrade, Inc. (Clarence, NY) introduces a new line of 1.3 hp air tools. These new high quality air tools are available as a Right-Angle Disc Sander and a Right-Angle Depressed Center Wheel Grinder.

Available in 4”, 4-1/2” and 5” diameters, the tools are excellent for fast stock removal, metal clean up prior to welding, removal of weld beads and various material removal applications. The Depressed Center Wheel Grinder is available in either 12,000 rpm or 13,500 rpm. The grinder is ideal for use with Type 27 Grinding Wheels. The 1.3 hp Disc Sander, available in 12,000 rpm, is for use with a wide variety of coated abrasives.

The tools feature a governor assembly for maintaining rpm under load. Also included is a safety-lock throttle to prevent accidental start-up and a spindle lock for fast, easy abrasive/wheel change. A two-position side handle for left or right-hand use is included. This vibration-dampening handle also reduces vibration to the operator’s hand. This line of air tools was also designed with a wick lubrication system, which extends gear life when the tool is properly lubricated with gear oil. Also included is a 360° rotational exhaust for directing the exhaust away from the operator. The Depressed Center Wheel Grinder also includes a safety guard and wheel flange kit. Made in the U.S.A.

Portable Beveling Tool up to 50 Times Faster than Hand Grinding

ESCO Tool (Holliston, MA) introduces a battery powered end prep tool that can bevel a torched-off pipe or tube end and replaces hand grinding for a precision fit up to enhance weld quality. The Tube Weasel Battery MILLHOG® is a fully portable right angle drive I.D. clamping end prep tool that is self-centering and can bevel, face and counterbore simultaneously. Ideally suited for process piping repairs on tube and pipe from 0.750” I.D. to 3.00” O.D., it is up to 50 times faster than hand grinding and provides repeatable results for precision fit up.

The Tube Weasel Battery MILLHOG uses the secure EscoLock™ blade lock system and provides chatter free operation. All clamping components including the draw rod are heat treated and provide the strength to rigidly secure the tool on the I.D of the pipe or tube. The 6.2 Ah battery is rechargeable using 120/220 VAC.

Clean Stainless Steel TIG Welds and Surfaces to Perfection

Fronius USA LLC (Portage, IN) offers the newest generation of Fronius MagicCleaner, available in two models. This advanced electro-chemical cleaner delivers the perfect finish on stainless steel TIG welds and surfaces, helping welders meet the highest standards of aesthetics and hygiene. In addition to beautifully polished TIG welds, this robust machine can also mark workpieces with logos or serial numbers. With the MagicCleaner it is easy to restore the protective layer over welds and stainless-steel surfaces. Clean and passivate workpieces in a single step.

Both the MagicCleaner 150 and MagicCleaner 300 supply the cleaning pad with electrolyte. This eliminates the need for dipping into open containers of cleaning fluid. The included pads and brushes penetrate corners and gaps, ensuring optimal cleaning with minimal use of materials. Electro-chemical cleaning is significantly more resource-efficient than conventional pickling in chemical baths and does not attack the material, as sandblasting does.

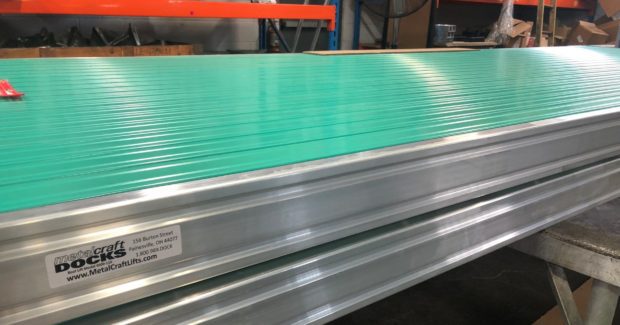

Scan and Spray: Programming Free Powder Coating

Gema USA Inc. (Indianapolis, IN) introduces the next generation of dynamic contour detection with a high-powered duo of advanced precision technologies — the high-load ZA16 Vertical Reciprocator Axis and the UA05 Gun Axis with 3D Scanner — that together offer the best in programming-free automated powder coating. With a superior combination of new laser scanners, improved software, and the latest axes, now the thinnest or most uniquely shaped objects can be precisely detected and coated.

Gema’s Dynamic Contouring solutions offer greater flexibility without any reprogramming, while correctly positioning each powder gun for automatic coating of parts. Faster 3D scanning allows for quicker line speeds, finer definition of complex geometries, and expansion of your application capabilities. With the “Scan & Spray” process developed by Gema, users achieve improved coating quality and consistency with increased first coat transfer efficiency. The target distance from the gun nozzle to the coating object adjusts automatically and measurably reduces both overspray and powder consumption.

Another advantage of Gema’s Dynamic Contour Detection is its unlimited scalability, covering small objects to XXL parts. This scalability and the resulting greater application flexibility, make Dynamic Contour Detection an ideal alternative to classic coating concepts and robot applications. For companies aiming for higher automation and increased productivity, without any programming effort, Dynamic Contour Detection is an ideal solution.

Gel Removes Soil, Rust, and Heat Tint/Weld Burn

Madison Chemical (Madison, IN) offers TreadBrite™ Edge Gel cleaner that removes soil, laser scale, rust, and heat treat scale, including heat tint/weld burn by simultaneously cleaning and brightening the surface through an etching process. This viscous gel contains a balanced blend of surfactants and acids, and is designed for use on aluminum, mild steel, stainless steel and copper. It is ideal for fabricated metal surfaces, especially where L series stainless is used and post-weld clean-up is required, where an exposed metal edge has been aggravated by CO2 laser cutting, or in areas where sulphurized cutting oils and metalworking fluids have damaged stainless steel surfaces.

The cleaner is ideal for cleanup of severely fouled press brakes or other fabrication equipment, including removal of all class I rouges and many class II and class III rouges.

New Abrasive Process Solutions Program Solves Wide Range of Grinding and Finishing Challenges

Saint-Gobain Abrasives (Worcester, MA), one of the world’s largest abrasives manufacturers, offers the new Norton Abrasive Process Solutions (APS) Program. The program helps customers determine the optimal grinding or finishing solution for the application at hand, ranging from simple to complex, off-hand or automated, and for metal fabrication, production grinding and virtually any abrasives operation. The program provides access to 30 different machines and a new state-of-the-art APS Robotic Automation Cell, which is at the core of the program located at the Higgins Grinding Technology Center in Northborough, Mass. The APS team provides abrasive process development, optimization, automation and in-house testing. Services encompass the testing and optimization of new abrasives, improving quality and/or throughput, and trying entirely new and customized processes.

The program is an extension of the customer, where tests can be conducted so that customers do not have to re-assign limited in-house resources and pause their own production.

The APS Automation Cell’s industrial robot has a 210-kg load capacity. The robot is fitted with an end-of-arm gripper to allow for part-to-media processing, as well as tool changers that use traditional hand tools to perform abrasive-to-part processing.

The cell can deliver abrasive-to-part and part-to-abrasive applications, wet/dry processing and uses a full range of abrasives such as coated, non-woven, thin wheel, bonded and superabrasives. Equipped with a verified turnkey solution, manufacturers can then contact an automation system integrator to implement the solution, which avoids costly trial and error at the integrator level.

Self-centering Honing Tools Conform to Bore Surface to Provide Even Surface Finish

Osborn’s (Richmond, IN) ATB™ NovoFlex™ is a self-centering tool that will conform to the bore surface providing a consistent, even surface finish over the life of the tool. Because of its round, abrasive beads fastened to the ends of flexible filaments, it will provide an “edge break” not possible with conventional honing stones.

ATB NovoFlex honing tools are available for hole diameters ranging from 0.196-to-8.000″. Grit is available in silicon carbide and aluminum oxide in sizes from 60-to-320 grit for your application. Typical applications include honing, creating cross hatched surface pattern for oil retention, cylinder port area deburring and eliminating inside flashing. These brushes are ideal for reaching into holes and crevices where other brushes cannot.

Osborn’s small diameter ATB NovoFlex tools are designed with round, abrasive beads fastened to the end of flexible nylon filaments sized to address smaller applications such as brake cylinders, hydraulics and valve guides. The longer brush length of Osborn’s heavy-duty ATB NovoFlex tool tackles tough honing projects with efficiency.

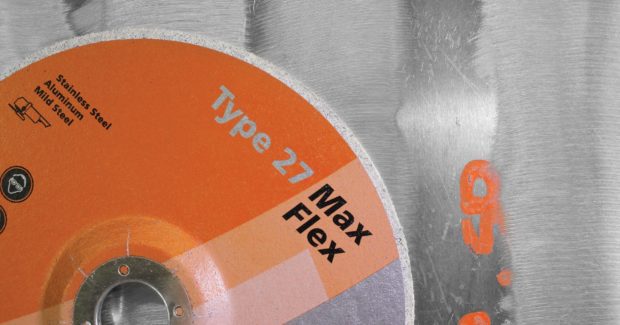

Blending Wheel for Reducing Finishing Steps

Rex-Cut Abrasives’ (Fall River, MA) Type 27 Max Flex blends and finishes flat and contoured surfaces in one step. Providing a wide surface contact area for optimum blending control and a uniform finish, these abrasive discs can grind, blend, and finish light welds in one step or blend and finish scratches after aggressive grinding applications.

Compared to flap discs, Max Flex provides a consistent metal removal rate and surface finish throughout the life of the wheel. Due to the cotton-fiber construction, Max Flex has a very long product life.

Conforming to the weld as it runs, Max Flex minimizes the amount of passes it takes to get to a desired finish. The wide surface contact area prevents gouging of the base metal and leaves a #4 finish on stainless steel.

Max Flex can be used at a 45° angle for an increased metal removal rate or a 30° angle for a better surface finish. Suited for stainless steel, carbon steel, mild steel, aluminum, brass and exotic metals, Max Flex is available in 4-1/2”, 5”, 6”, and 7” diameters in either 36 or 54 grit.

High-quality Edges Without Post-processing

Ergonomic edge preparation tools from TRUMPF (Farmington, CT), the TruTool TKA 1500 and TruTool TKA 700, assist edge preparation for painting, welding or applying any type of coating. The tools can produce polished metal chamfers on both straight edges and inner or outer contours, as well as radii of up to four millimeters. Designed to offer zero emissions and no flying sparks, the edge trimmer tools offer outstandingly high productivity combined with simple, ergonomic operation.

Metalworkers, steelworkers, agricultural and earth moving equipment manufacturers among others use TRUMPF’s edge preparation tools to produce clean, oxide-free edges. They are the tools of choice for chamfering metal sheets, for instance, to prepare them for powder coating, painting or the application of weld seams. They are also used to round off sharp edges and remove burrs, reducing the risk of injury to workers. Angles of 30, 45 and 60 degrees can be produced in mild steel, stainless steel and aluminum depending on the requirements in each case.

The edge trimmer will allow you to create custom bevel lengths of up to 15 mm with 30-, 45- and 60-degree angles. You can adjust the desired bevel length without tools. Consistently achieve quality edges — that means no reworking for you. This is because the cutting process is extraordinarily fast and keeps the materials from oxidizing or deforming.

TRUMPF has equipped its TruTool TKA 1500 and TruTool TKA 700 with multi-edge cutters that guarantee a long service life — perfect for mild steel, aluminum and stainless steel. The operator can choose between different multi-edge cutters depending on whether they wish to apply a straight edge or a radius, opting for either three or four cutting edges.

The TruTools come with a powerful 2600/1700-watt motor. The ‘soft start’ system ensures that the tool always starts up smoothly and slowly, not with a jolt. An overload protection feature prevents the motor from overheating even in continuous use, while an integrated safety feature prevents the tool from starting up accidentally following an unexpected power cut.

Avoid Spatter and Rework with Premium Anti-Spatter Solution

The hassles, costs, and delays caused by spatter are well known in the metalworking industry. The main causes of these imperfections are typically poor surface preparation and incorrect equipment settings.

The adherence of spatter to a base material is a time-consuming challenge frequently faced by welders. It is visually undesirable and can lead to part assembly interference.

There are different solutions to preventing weld spatter from building up and causing quality and productivity issues.

Manual cleaning with hammers and chisels for example is a labor-intensive task that causes the most delays and disruptions while highly contributing to operator fatigue.

Grinding or sanding can be an effective method to removing spatter, but they can just as easily damage the surface of your metal and disrupt production. This damage is often costly and time consuming, having to rework the piece and restore it to its desired finish.

There’s a faster, easier, and safer process.

The WALTER Surface Technologies’ (Windsor, CT) E-WELD 4™ is a premium anti-spatter solution meant to protect your workpieces and is guaranteed not to cause weld porosity. It eliminates the need for this costly rework by forming a barrier on the material minimizing the adherence of spatter to the base metal making it easy to remove after welding. The non-toxic, non-flammable and silicone-free formula does not contaminate the weld pool, and also retracts in the presence of heat, leaving the welding area liquid free. This contributes to the reduction of weld porosity or weld cracks.

It’s also an excellent corrosion resistance which makes it ideal for ferrous alloys and corrosion sensitive parts.