Total Chip Solution Reduces Volumes up to 90 Percent; Increases Recycle Value

Jorgensen now serves manufacturers as a single source for total metalworking chip and coolant processing systems.

Posted: May 12, 2022

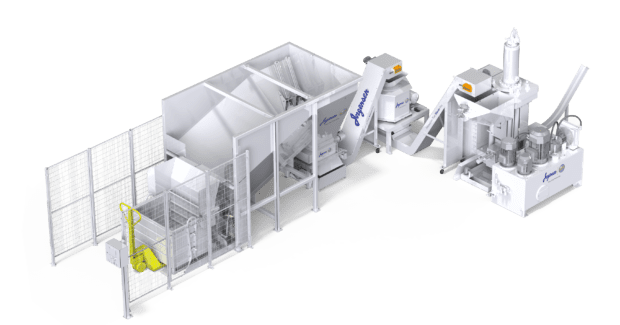

(Mequon, WI) — As a result of its recent partnership with S.F.H., Jorgensen Conveyor and Filtration Solutions now serves manufacturers as a single source for total metalworking chip and coolant processing systems. With standalone or fully integrated systems that transport, shred, wring and briquette chips and sludge, manufacturers can reduce chip volumes by as much as 90% and significantly increase their chip recycling value.

The volume reduction of aluminum, magnesium, copper, brass, steel and other types of metal chips represents a significant cost savings in labor, disposal, transport and storage. Jorgensen/SFH single and double-shaft shredders efficiently reduce chip size in preparation for centrifuging or briquetting. The volume reduction resulting from implementing a shredder also lessens the frequency of bin removal from a machine, giving a shop’s employees additional time to focus on other more productive work. Jorgensen/SFH offer a variety of shredder size options constructed per a customer’s material and desired chip output needs.

For maximum extraction of coolants and/or cutting oil, chip wringers from Jorgensen/SFH provide continuous, automatic operation at extremely low costs. Once collected, used coolant or oil can be processed through one of Jorgensen’s filtration units and is put back into the coolant system for reuse. In terms of chips, a lower moisture content also further increases their recycling value.

Jorgensen/SFH chip compactors collect chips directly under conveyors or in centralized treatment areas. Chips and fines enter the press then are compacted under hydraulic pressure to form solid briquettes and separates out residual coolant fluids for reuse. The compactors are a robust, space-saving solution for briquetting a variety of ferrous or non-ferrous metals in the form of chips, sludges or dust.

To easily and efficiently move chips from the manufacturing process through to shredding, wringing and briquetting, Jorgensen/SFH engineers conveyors to a customer’s exact application specifications, ensuring a proper fit and lasting solution. The company offers a wide variety of conveyors, all of which ensure long working lives and low required maintenance.